Real-time online individualized heat-exchanging intelligent temperature control system of mass concretes

A large-volume concrete and intelligent control technology, which is applied in the fields of temperature control, construction, and infrastructure engineering using electric methods, can solve the problem of coordinated control of temperature in multiple dam sections of a dam, no interconnection of equipment, temperature and flow data heavy workload etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Real-time, online personalized control is realized by water control in concrete water cooling, and the specific implementation plan is as follows:

[0048] (1) The interpolation numerical temperature measuring device 1 installed on the outlet pipe of each group of cooling water pipes;

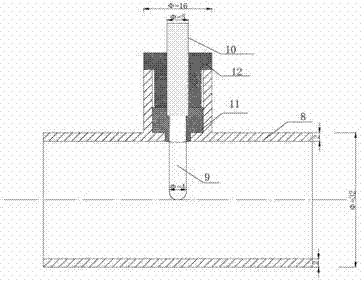

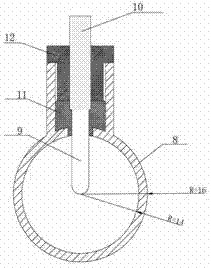

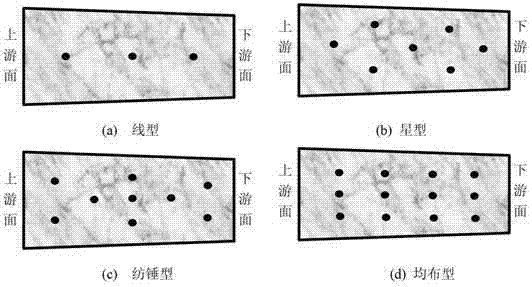

[0049] (2) The digital temperature sensor 2 pre-embedded in each point of the concrete block during pouring, the sensor embedding method see figure 2 ;

[0050] (3) The integrated flow temperature control device 7 for real-time collection and control of the water temperature and flow rate of the water pipes is installed on the water inlet pipe of each group of cooling water pipes. A control device that integrates the meter 5 and the interpolation value temperature measuring device 1 together.

[0051] (4) Intelligent control box 3, the control box equipment includes PLC and multi-channel temperature acquisition instrument, and uploads the real-time collected data to the server 4 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com