Variable geometry volute device

A volute, geometric technology, applied in engine components, machines/engines, internal combustion piston engines, etc., can solve the problem of not achieving effective engine matching, and achieve the effect of improving turbine air intake efficiency, easy control, and meeting performance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

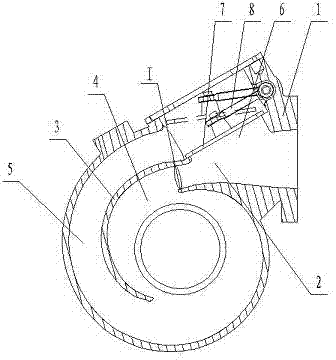

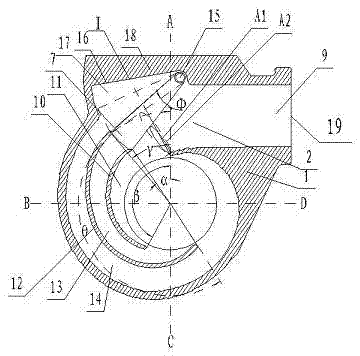

[0055] Example 1, such as figure 2 As shown, a variable geometry volute device includes a turbine volute 1, a volute inlet flow passage 2 is provided inside the turbine volute 1, and a volute inlet flow passage 2 is provided on the turbine volute 1 Connected volute air inlet 9;

[0056] The volute inlet flow passage 2 is provided with a first aerodynamic partition 10, and the first aerodynamic partition 10 divides the volute inlet flow passage 2 into a volute inlet inner flow passage 11 and a volute inlet outer flow passage. , the volute air intake outer flow channel is located on the circumferential outside of the volute air intake inner flow channel 11, and the cross-sectional area of the volute air intake outer flow channel is larger than the sectional area of the volute air intake inner flow channel 11 ;

[0057] A second aerodynamic baffle 12 is provided in the volute air intake outer flow channel, and the second aerodynamic baffle 12 divides the volute air intake ...

Embodiment 2

[0083] Example 2, such as Figure 5 ,Such as Image 6As shown, on the basis of Embodiment 1, the cross-sectional shape of the intake regulating valve 7 can also be designed as a rectangular structure, from the center of the intake regulating valve shaft 15 to the end of the intake regulating valve 7 near the volute inlet 9 The ratio of the distance L1 to the total length L0 of the air intake regulating valve 7 ranges from 1 / 4 to 1 / 2.

[0084] The two ends of the air intake regulating valve 7 are inclined-plane structures respectively, and the inner wall 16 of the volute and the first pneumatic partition 10 are respectively provided with mating surfaces matching the two ends of the air intake regulating valve 7 .

[0085] According to the cross-sectional shape of the air intake control valve when it is a rectangular structure, the value of the first critical area A1 at the throat of the turbine volute in the low-speed working condition is the largest, and the third critical ar...

Embodiment 3

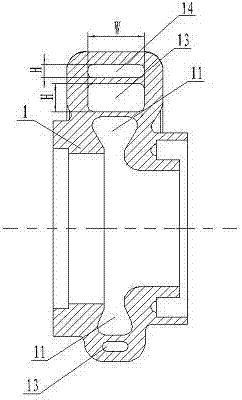

[0087] Example 3, such as Figure 8 As shown, on the basis of Embodiment 2, the cross-sectional shape of the air intake regulating valve 7 is designed to be a rectangular structure, and the air intake regulating valve shaft 15 is arranged at one end of the air intake regulating valve 7 close to the first aerodynamic partition 10 .

[0088] The end of the intake regulating valve 7 away from the intake regulating valve shaft 15 has a slope structure, and the inner wall 16 of the volute is provided with a mating surface that matches the intake regulating valve 7 .

[0089] Such as Figure 8 , Figure 9 As shown, the working principle of this embodiment 3 is the same as that of embodiment 1, and the working process of the engine in low-speed working conditions and high-speed working conditions is the same as that of embodiment 1, the difference is that when the engine is in the range of medium-speed working conditions , the air intake adjustment valve shaft 15, driven by the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com