High-load super transonic axial gas compressor aerodynamic design method

A technology of axial flow compressor and aerodynamic design, applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., can solve problems such as difficulty in suction pipeline layout, decrease in blade strength, increase in number of blades, etc., to reduce design difficulty, Efficient turning and reducing the effect of absolute Mach number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0024] Specific implementation mode one: as Figure 1~1 As shown in 1, the aerodynamic design method of the high-load super-transonic axial-flow compressor described in this embodiment is realized through the following steps:

[0025] Step 1. High-load aerodynamic design of moving blades:

[0026] The rotor blade is designed with high load and large rotation angle. Under the premise of axial air intake, the outlet of the rotor blade can be axially aligned with the airflow direction (see Fig. 7); at this time, the rotation angle of each section of the rotor blade is equal to the relative airflow angle of the inlet (relative to speed and axial angle), the size of each section rotation angle θ max The value of can be determined by the formula (1); considering the relationship between the inlet axial velocity and the peripheral velocity, the airflow rotation angle on each section of the moving blade can reach 50-65 degrees; at this time, the twisting speed on each section is equa...

specific Embodiment approach 2

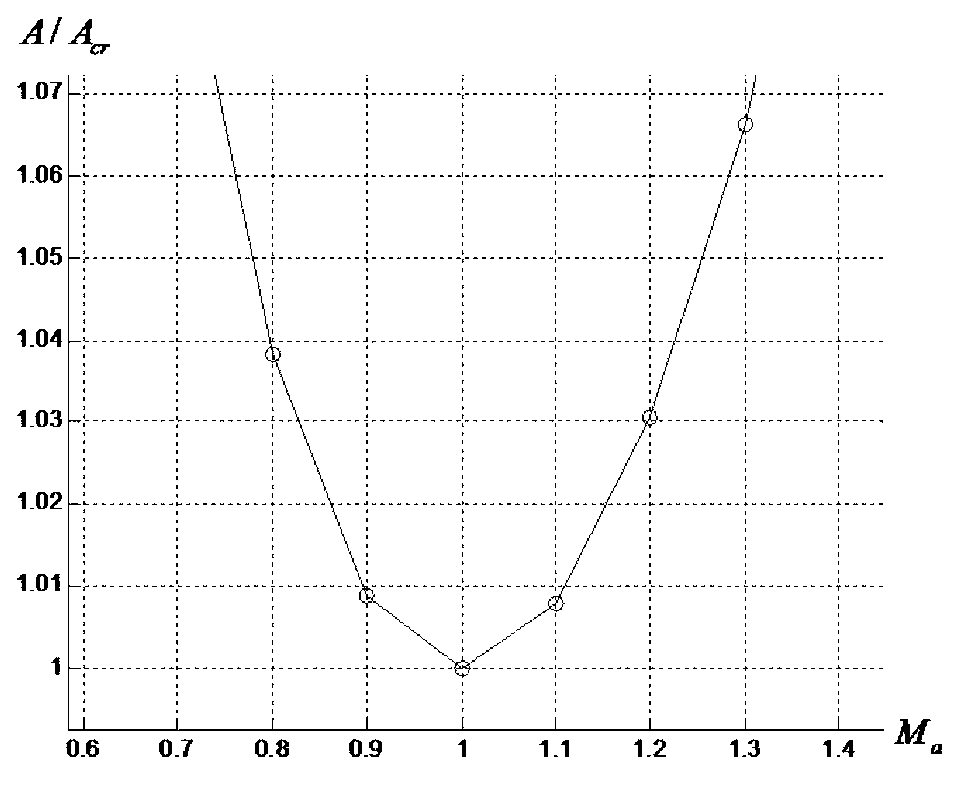

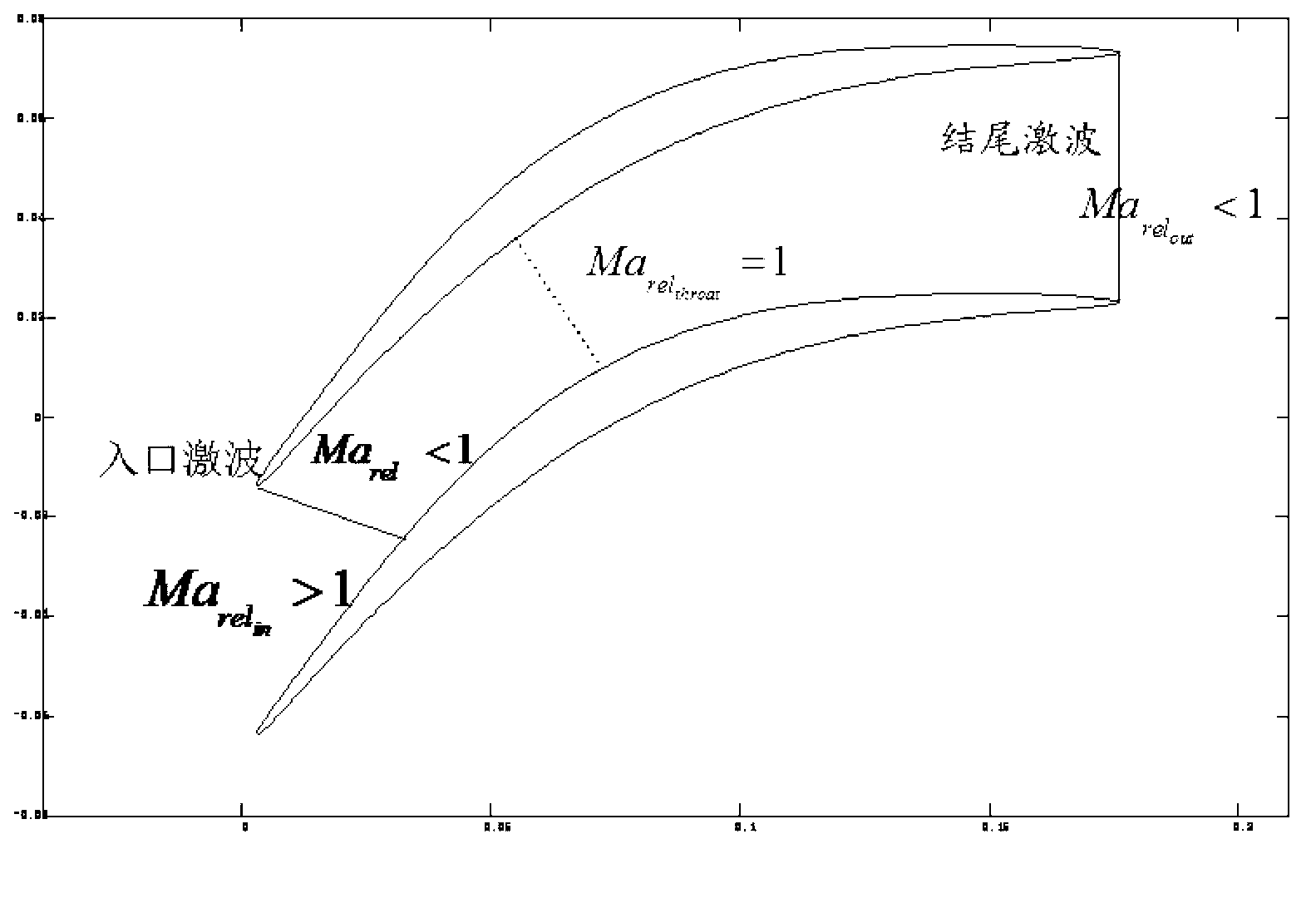

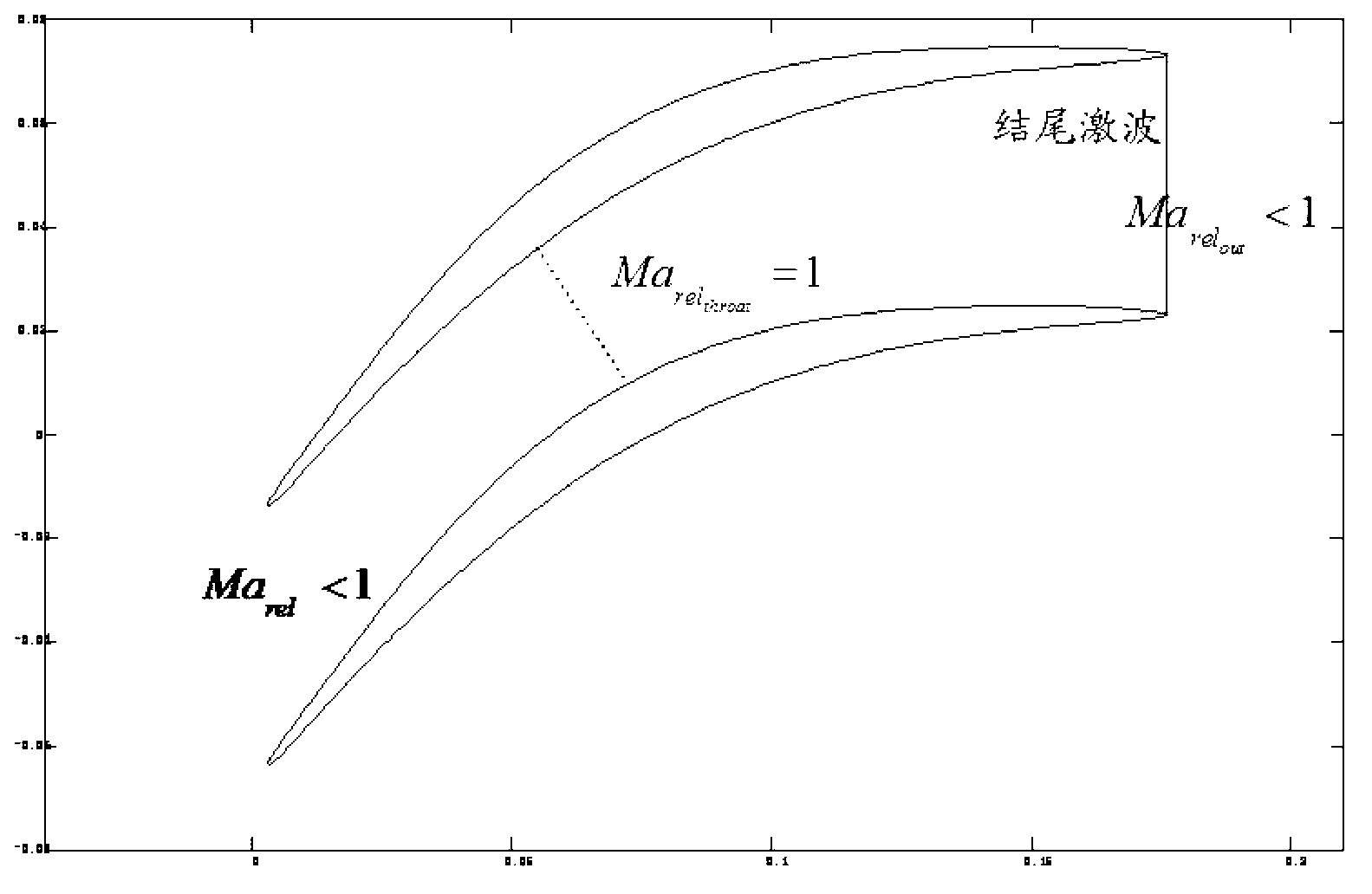

[0033] Specific implementation mode two: combination figure 2 (or image 3 ), Figure 4 and Figure 5This embodiment will be described. Under the condition that the circumferential speed of the moving blade remains constant, the high-load aerodynamic design of the moving blade is carried out by increasing the blade cascade rotation angle. In the case that the incoming flow at the rotor blade inlet is axial air intake, the maximum rotation angle of each section can be calculated by formula 1. At this time, the relative velocity direction of the rotor blade outlet airflow is along the axial direction. The design of the hub can then be combined with the rim, see Figure 4 , so that the meridian flow channel shrinks greatly, and the area of the flow channel decreases. After points C and D, the meridian flow channel tends to be flat, and at this time, the total flow area obtained from the cross-sectional airfoil of each elementary level increases. In addition, in order to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com