Direction self adjusting ventilating cowl

A ventilation cap and self-adjusting technology, applied in ventilation systems, space heating and ventilation, heating methods, etc., can solve the problems of low conversion efficiency and large initial investment, saving energy, improving efficiency, and excellent selective moisture permeability The effect of capacity and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

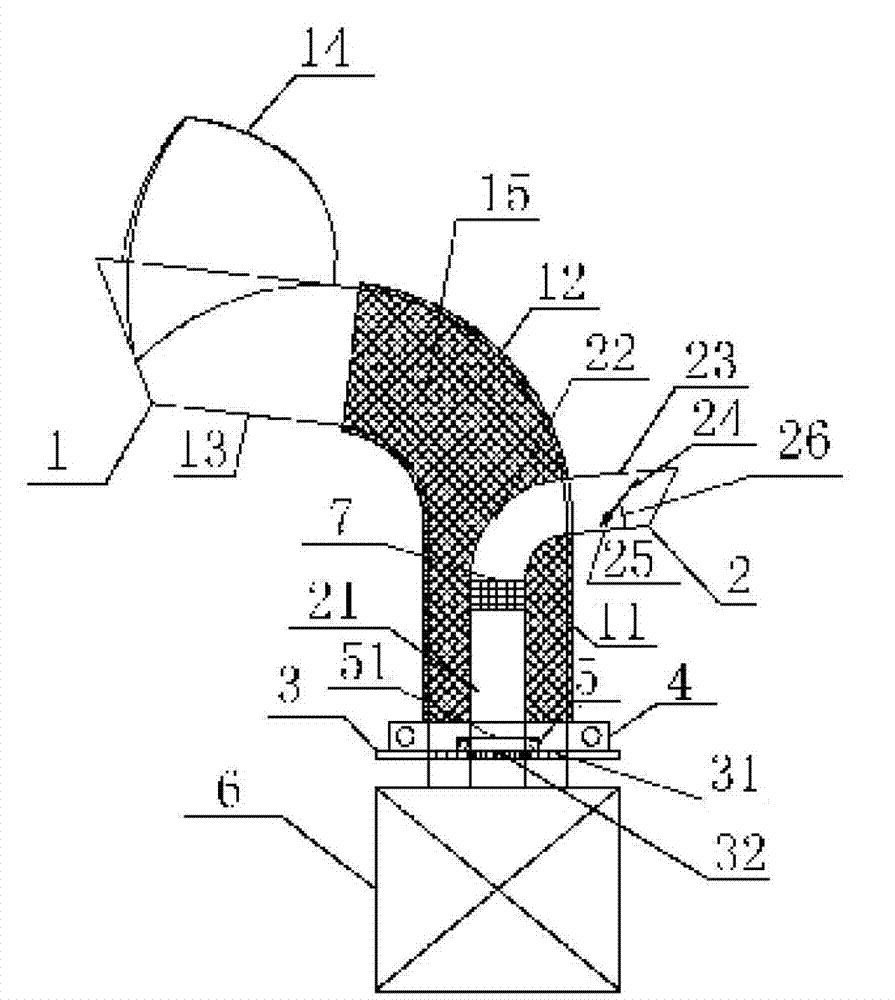

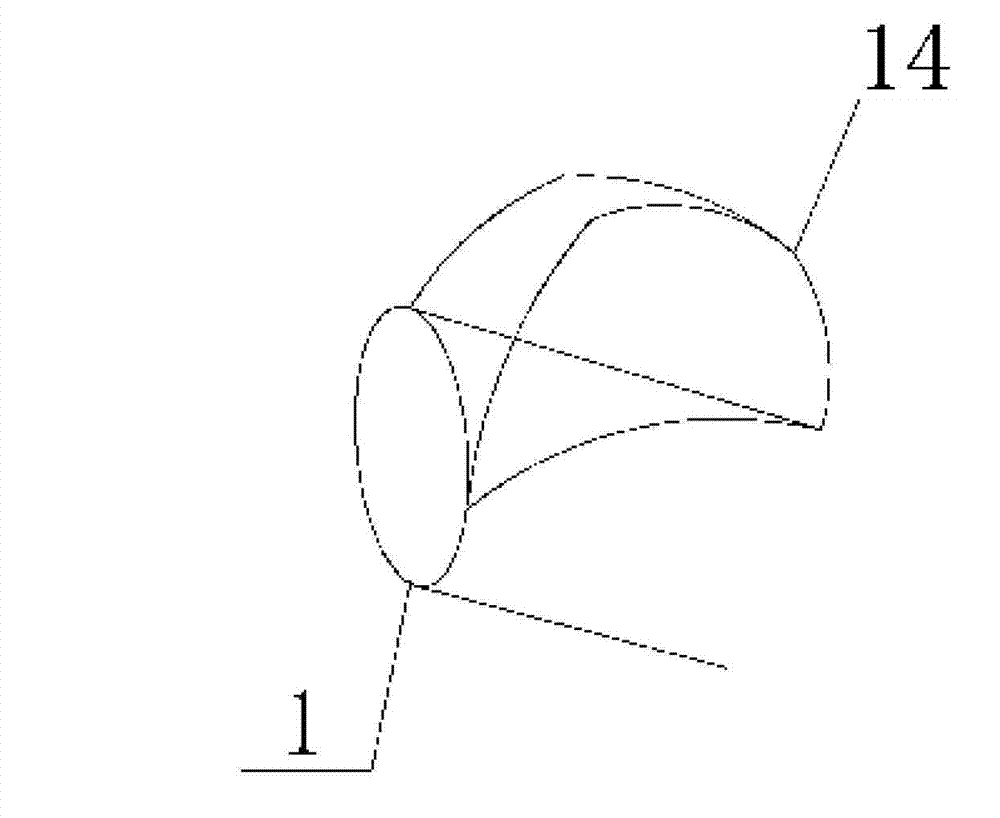

[0023] The specific structure and working process of the present invention will be further described below in conjunction with accompanying drawings.

[0024] As shown in the accompanying drawings, the ventilation cap of the self-adjusting direction of the present invention includes an exhaust pipe 1, a vertical exhaust section 11, a transitional exhaust section 12, a horizontal exhaust section 13, a wind cap 14, and a solar heat collection and heat storage material. 15. Air inlet pipe 2, vertical air inlet section 21, transitional air inlet section 22, horizontal air inlet section 23, baffle plate 24, rotating shaft 25, spring 26, bearing seat 3, vent hole 31, second vent hole 32, The first bearing 4, the second bearing 5, the inner hole 51, the total heat exchanger 6, and the air filter 7.

[0025]The bearing housing 3 can be fixed on the roof through threaded connection, and a full heat exchanger 6 is installed under it. The first bearing 4 and the second bearing 5 are fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com