Fatigue life calculation method for engine parts based on road cycle working condition

A technology of fatigue life and cycle working conditions, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problem that the fatigue life of engine parts cannot be effectively and uniformly calculated, and achieve the effect of speeding up work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

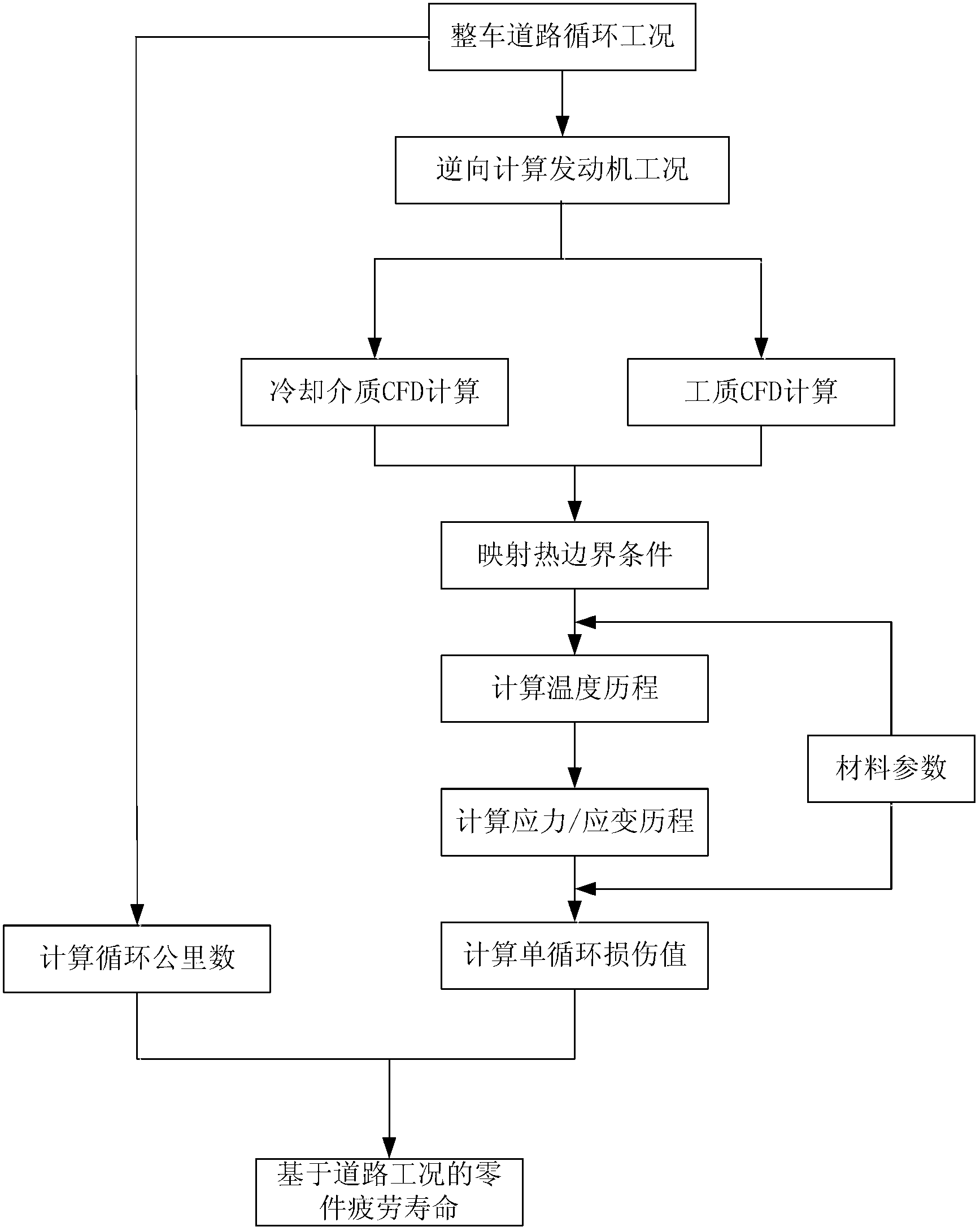

[0023] Such as figure 1 Shown is the flow chart of the present invention, taking the piston as an example of a high-temperature part, using the present invention to calculate its fatigue life, including the road cycle life of the whole vehicle and the bench test life.

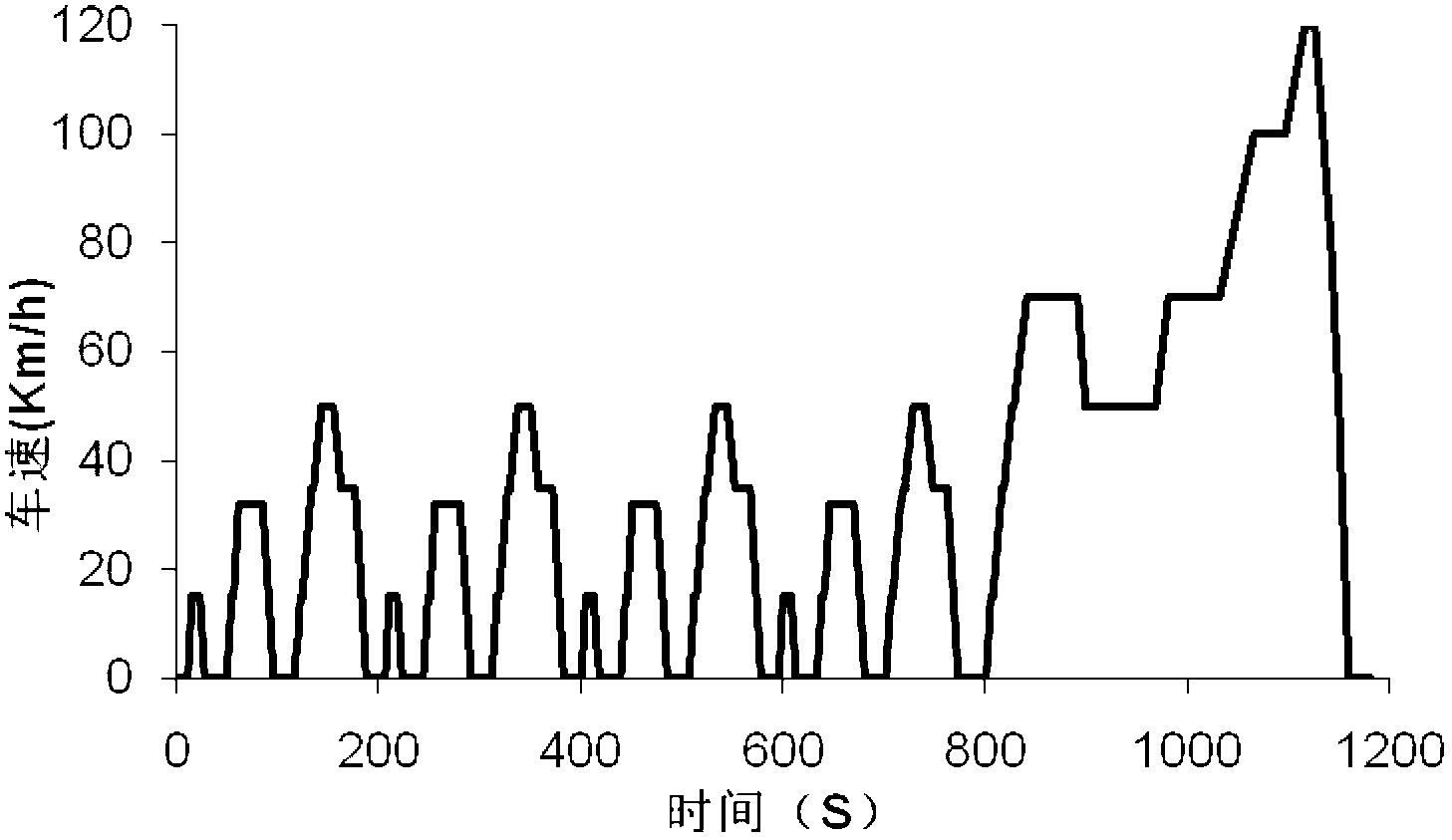

[0024] Such as figure 2 Shown is the European road cycle conditions, it can be obtained that the cycle time per cycle in the European road cycle conditions is 1180 seconds, and the mileage per cycle is 11.01Km.

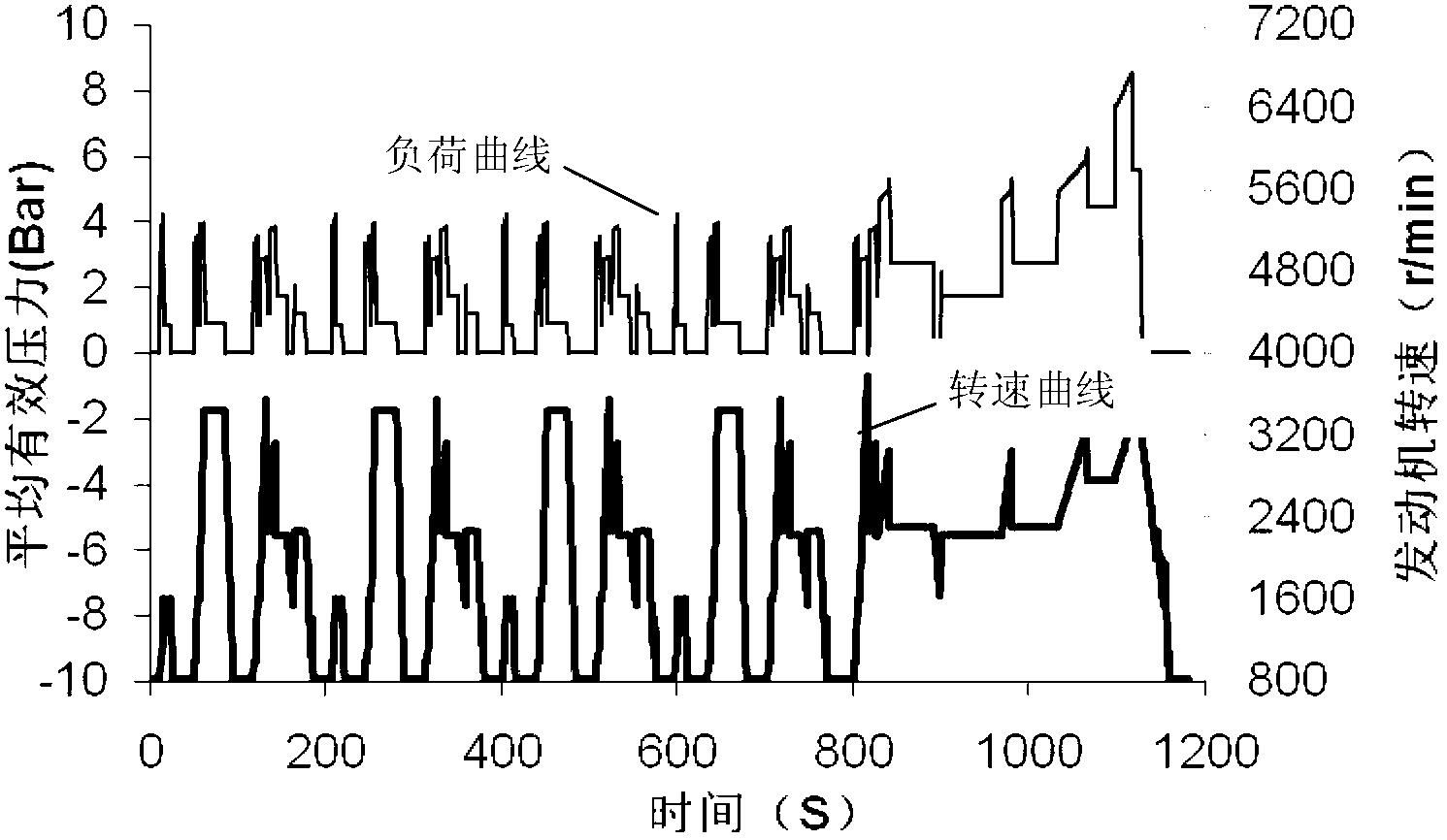

[0025] Calculate engine operating conditions according to road conditions, including speed n, engine mean effective pressure P e and engine effective power P me ;

[0026] Calculate the engine speed corresponding to each moment when the car is running on the road as Among them, n is the engine speed (r / min), u is the vehicle speed (m / s), i 0 main reduction ratio, i g is the gear ratio of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com