Wireless intelligent inspection method of warehouse and special robot

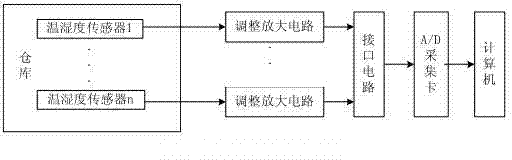

An intelligent inspection and robot technology, applied in the field of electronic technology applications, can solve the problems of arranging a large number of wires, inconvenient practical application, limiting the flexibility of sensors, etc., and achieves the effects of good real-time performance, easy installation and high measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

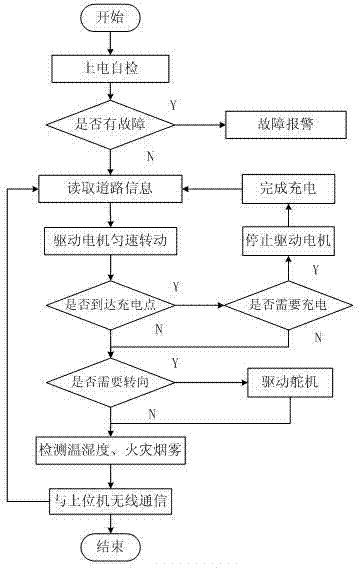

[0017] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

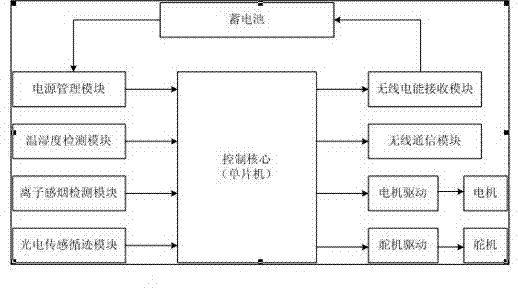

[0018] Refer to attached figure 2 , a wireless intelligent patrol robot for warehouses, including a control core module, a power management module, a temperature and humidity detection module, an ion smoke detection module, a photoelectric sensor tracking module, a wireless energy receiving module, a wireless communication module, a motor and its Drive, steering gear and its drive and battery, power management module, temperature and humidity detection module, ion smoke detection module and photoelectric sensor tracking module are connected to the control core module, and the output of the control core module is connected to the wireless power receiving module and wireless communication module , the motor and its drive, the steering gear and its drive, the output of the wireless power receiving module is connected to the battery, and the batter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com