Cable bending and molding device

A bending forming and cable technology, which is applied in the direction of line/collector parts, electrical components, circuits, etc., can solve the problems of low work efficiency, troublesome bending and forming, irregular forming, etc., so as to improve work efficiency and facilitate follow-up work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

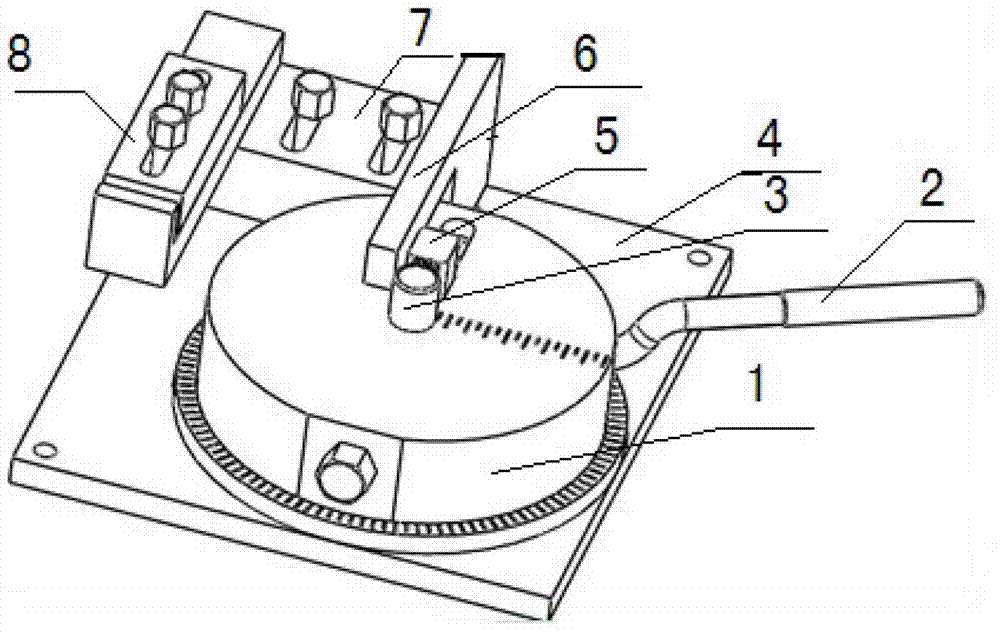

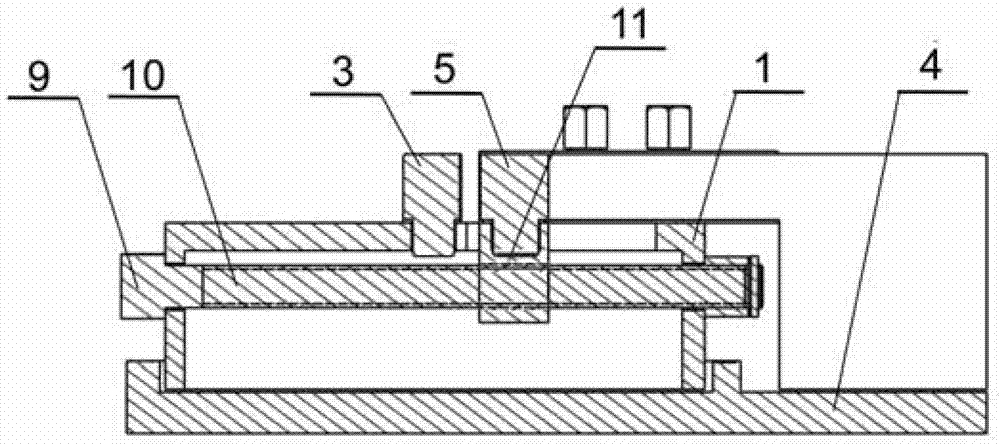

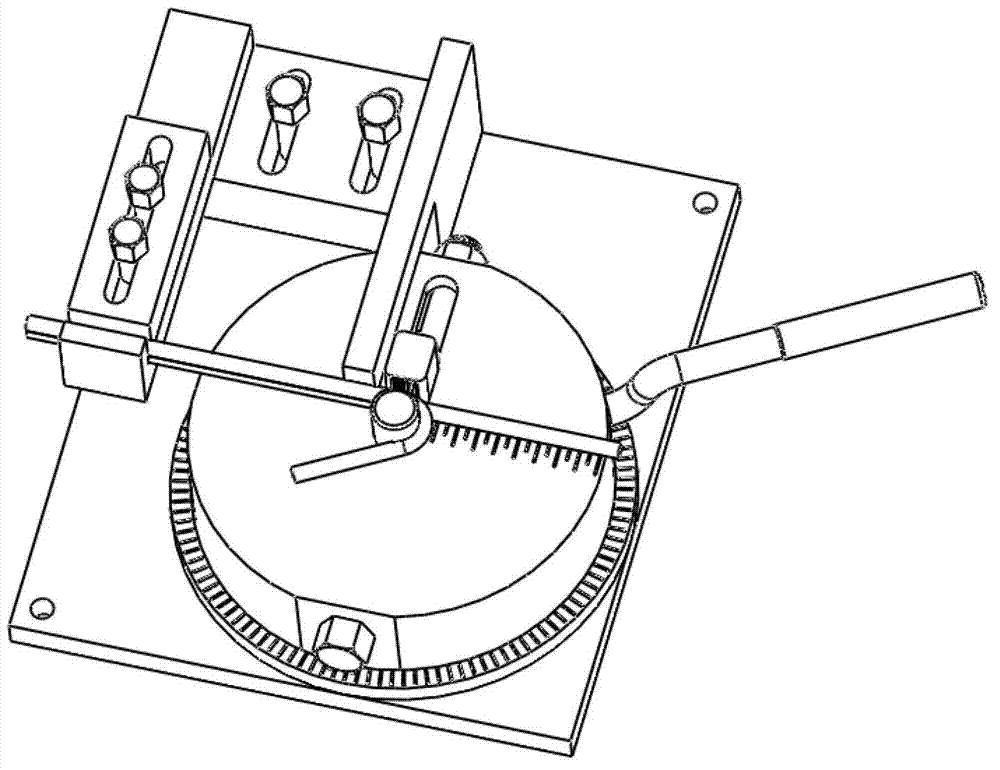

[0013] like figure 1 , figure 2 As shown, a cable bending forming device includes a base 4, a limit plate 7, a circular turntable 1, a turntable handle 2, baffles 6, 9, an operating nut, 10, a clamping screw, 11, and a nut slider Assemblies, the central forming mold 3 and the clamping block 5, the limit support plate 7 is fixed on the base 4, the limit support plate 7 is provided with a baffle plate 6 and a wire diameter adjustment plate 8, and the wire diameter adjustment plate 8 is provided with an adjustment The chute is equipped with fixing bolts in the adjustment chute, the circular turntable 1 is set in the circular groove of the base 4, the turntable handle 2 is fixed on the side of the circular turntable 1, and the center molding mold 3 is installed on the side of the circular turntable 1. In the center, the clamping block 5 is installed on the nut slider assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com