Embedded sine-profile permanent motor rotor

A permanent magnet motor, built-in technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of unstable operation and easy falling off of the motor, and achieve high efficiency and large salient pole rotation The effect of torque and motor running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

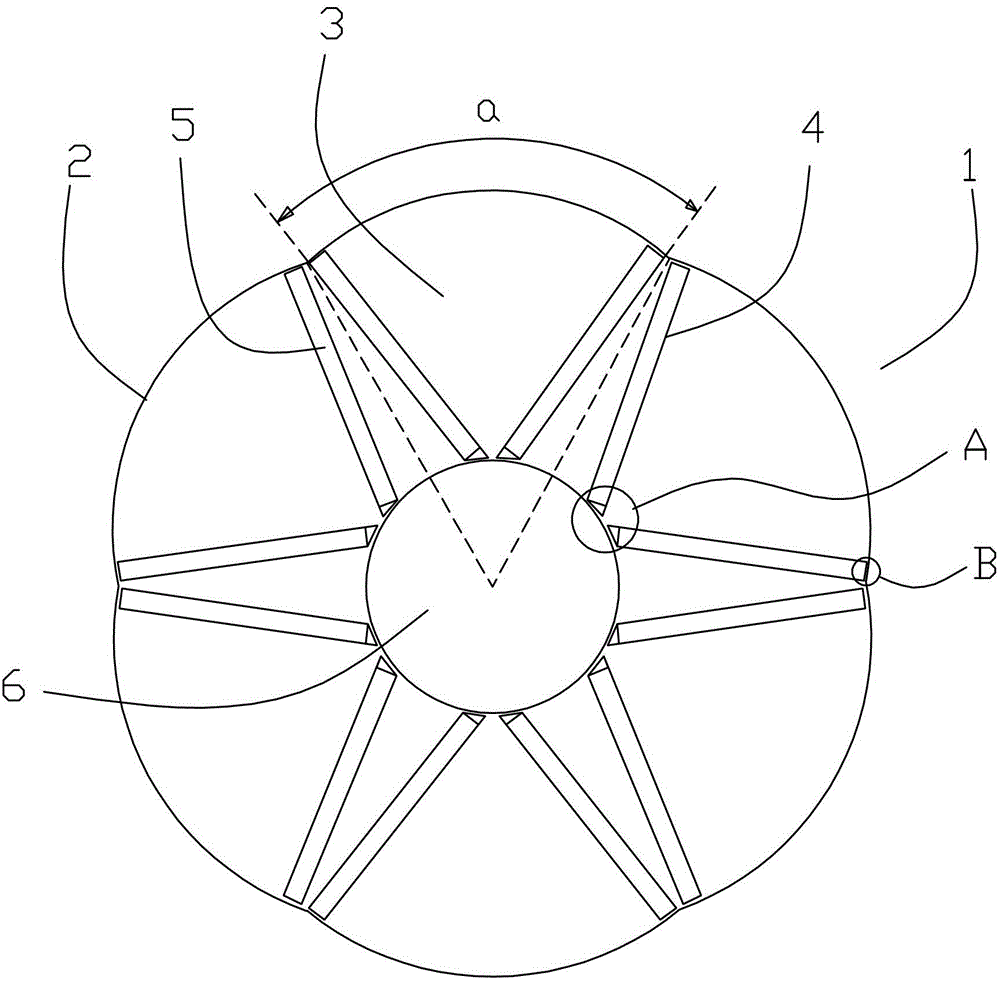

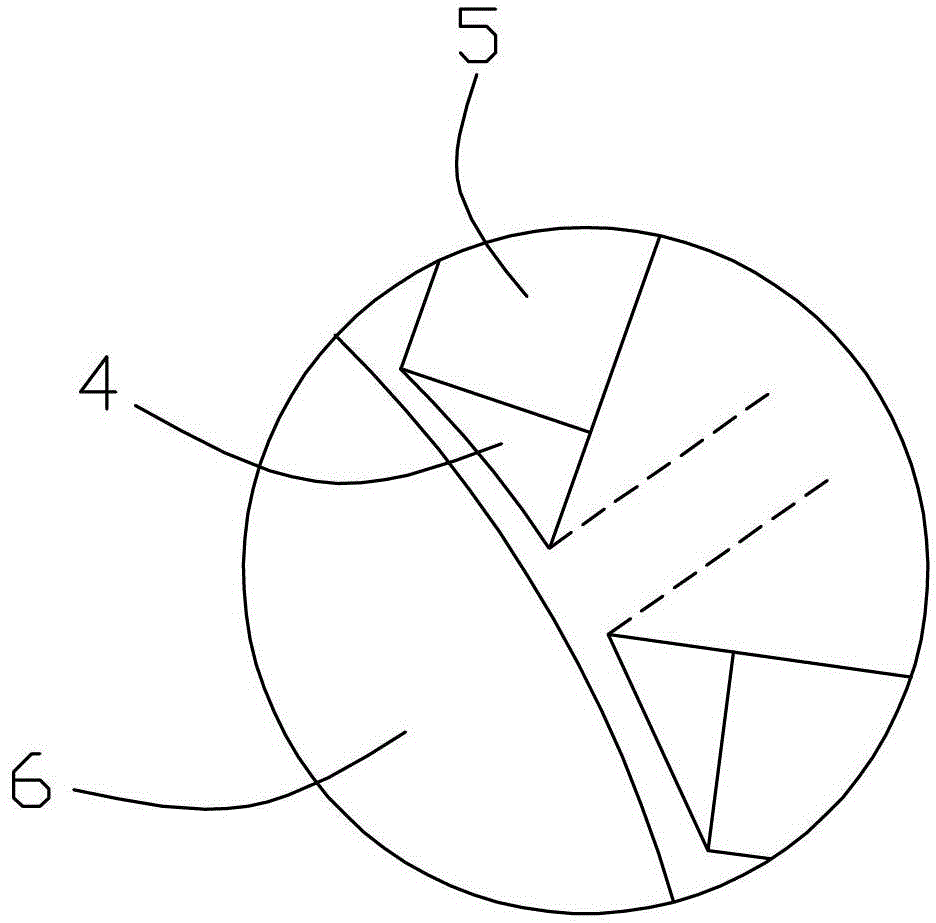

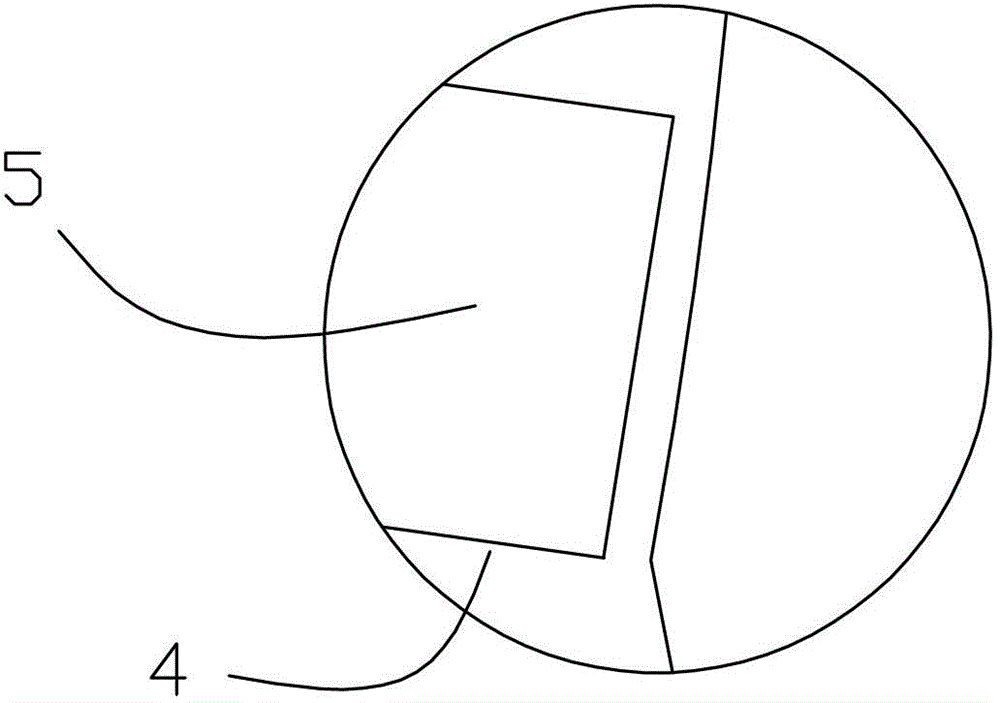

[0016] In this embodiment, an embedded sinusoidal surface permanent magnet motor rotor, such as figure 1 As shown, the surface of the rotor is provided with several continuously connected arc-shaped protrusions 2 around the axis and in the axial direction. A bump is used as an example for explanation. The rotor is divided into several equally divided areas according to the line connecting the intersection point of adjacent protrusions 2 and the rotor axis, such as figure 1 In the part indicated by the dotted line, the rotor is divided into 6 equally divided areas. In each area, two slot bodies 4 arranged in an inverted figure-eight shape are arranged respectively. The slot bodies are elongated straight slots. At the end, the two ends of the protrusion refer to the two end points where the protrusion intersects with the outer circle of the rotor. The inner ends of the two grooves are close to each other and arranged near the rotor shaft hole 6. The two grooves are symmetrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com