Device for thermally treating substrates

A technology for substrates and processing chambers, applied in the field of heat treatment inner chambers, can solve problems such as damage to sensitive components, and achieve the effect of simplifying costs and low-cost production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

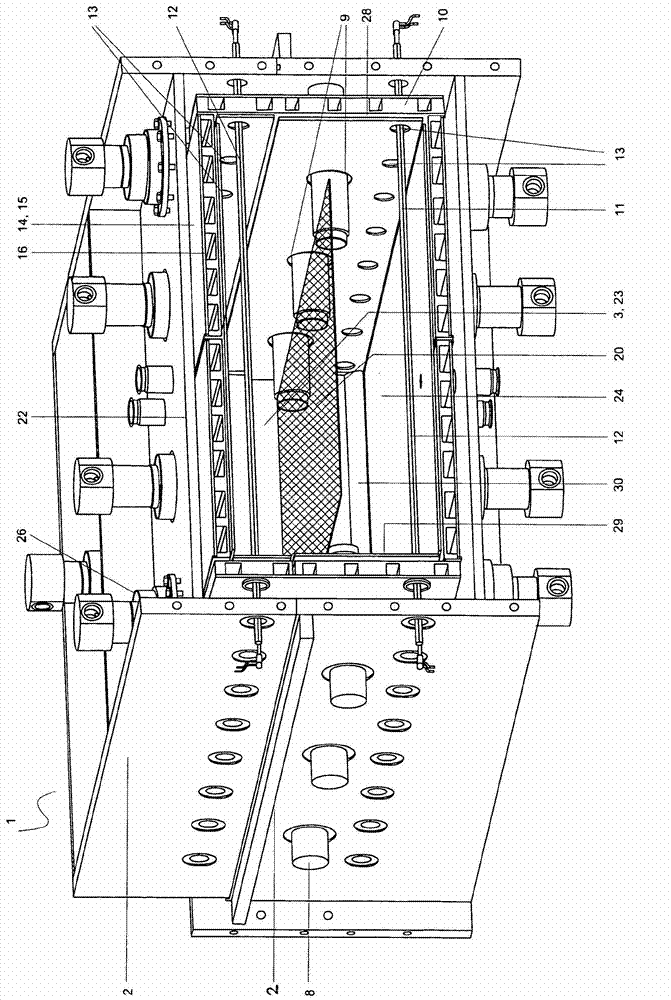

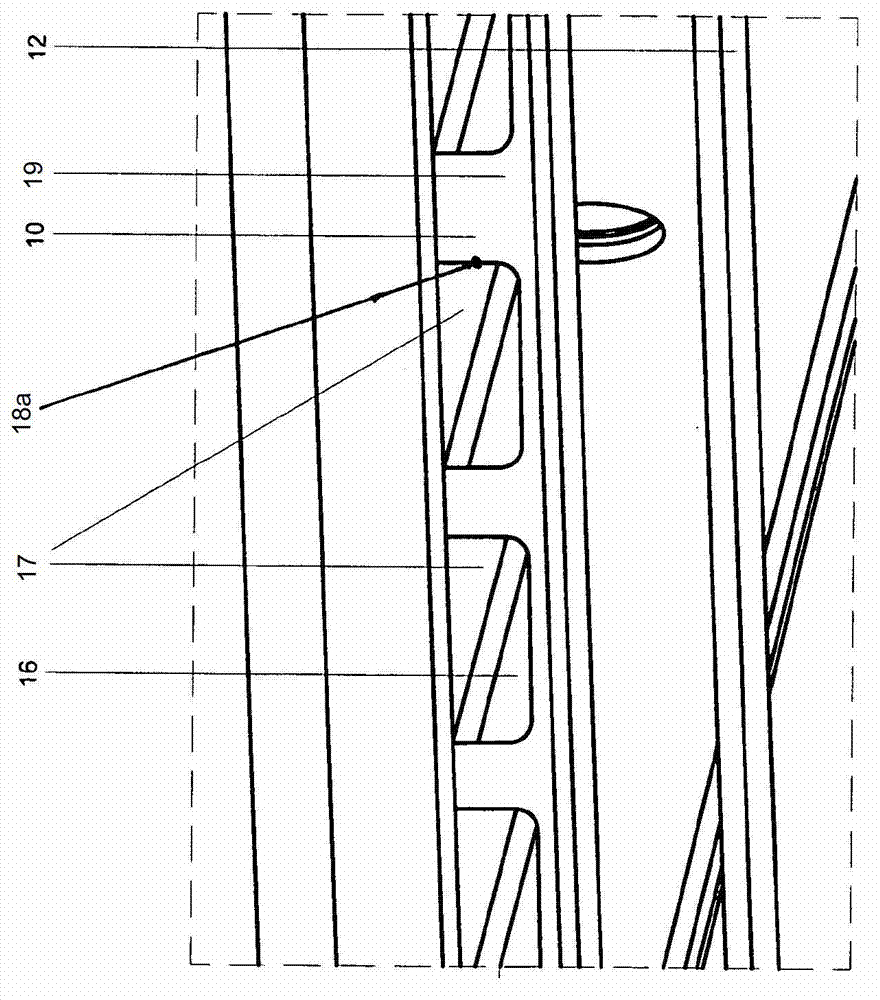

[0031] Mutually corresponding elements in the figures are marked with the same reference numerals. The figures represent embodiments schematically and do not repeat specific parameters of the invention. Furthermore, the drawings are only used to illustrate an advantageous embodiment of the invention, and it is not to be understood that the drawings limit the scope of protection of the invention.

[0032] figure 1 and 2 A perspective sectional view of a processing chamber 1 for thermally processing a substrate 20 is shown. The term "substrate" is to be understood here as any object to be treated, coated and / or coated, i.e. not only a (possibly pretreated) carrier material like this but also Support materials with single or multiple coatings are possible. exist figure 1 and 2 In an embodiment, the substrate is a flat workpiece, and the area of the workpiece may be between several square centimeters and several square meters.

[0033] Preferably, the substrate 20 can als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com