Supported nano nickel-based catalyst as well as preparation method and application thereof

A nano-nickel and supported technology, which is applied in the field of supported nano-nickel-based catalysts and their preparation, can solve the problems of easy fires caused by the operation of Raney nickel catalysts, high production costs of chloroquine side chain compounds, and loss of catalyst production. The effect of large-scale industrial production, simplified production operation process and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Another aspect of the embodiments of the present invention also provides the aforementioned method for preparing the supported nano-nickel-based catalyst, which includes: preparing the supported nano-nickel-based catalyst by co-precipitation and / or deposition-precipitation.

[0032] In some more specific embodiments, the preparation method may specifically include: mixing the mixed metal salt solution containing the main active component and the auxiliary agent, the lye and the metal salt solution of the carrier, the carrier oxide powder solution, the carrier Any one of the colloidal particle solutions is mixed, and then subjected to precipitation, aging, roasting and reduction treatment to obtain the supported nano-nickel-based catalyst.

[0033] Further, the lye is any one or a combination of two or more of sodium hydroxide solution, potassium hydroxide solution, sodium carbonate solution, and potassium carbonate solution, and is not limited thereto.

[0034] Further,...

Embodiment 1

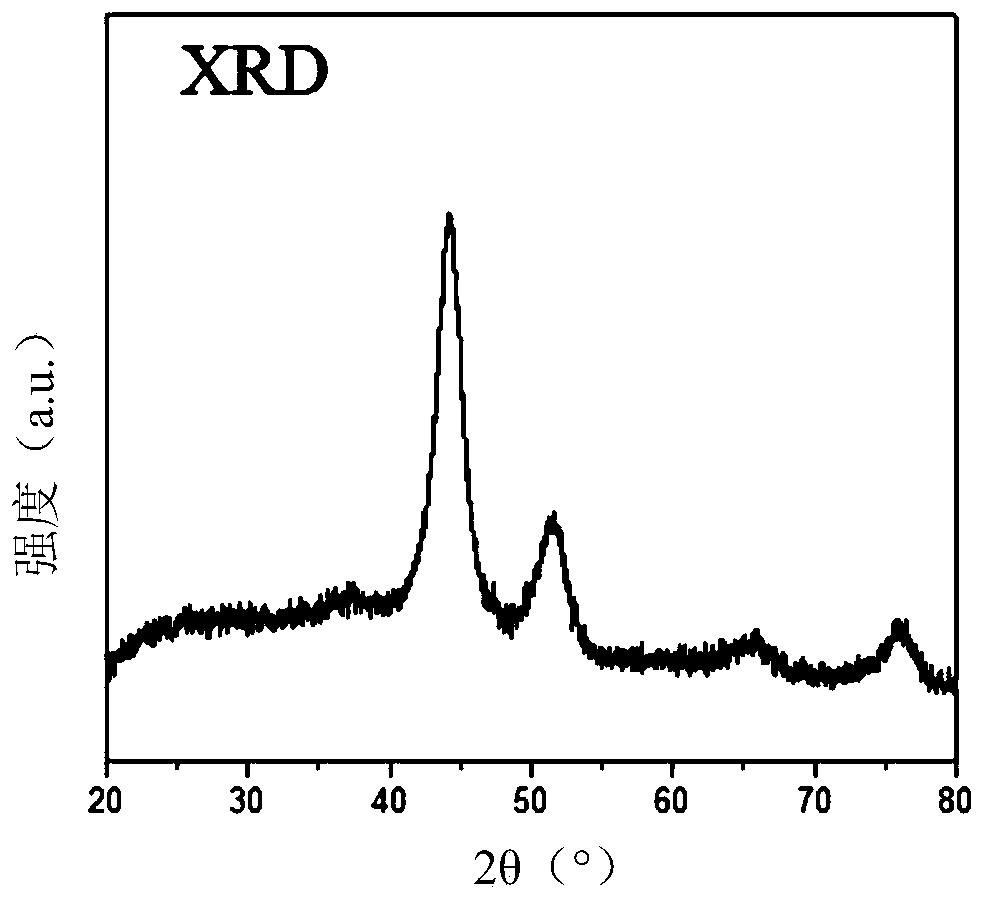

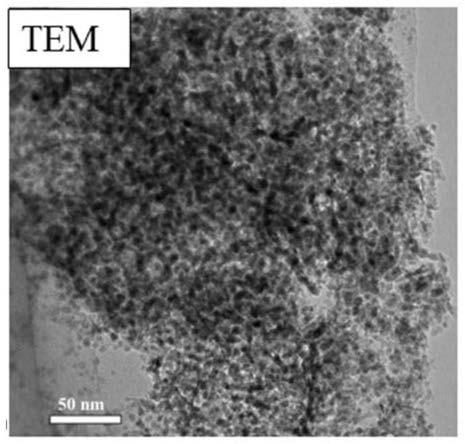

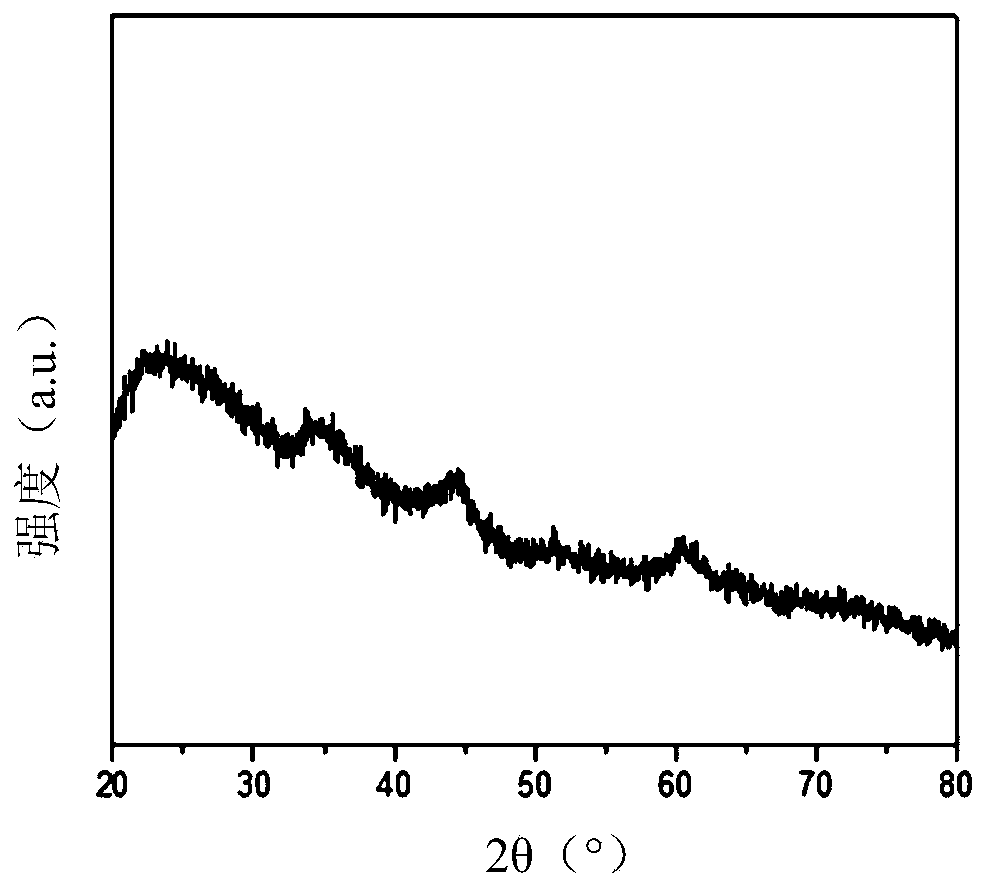

[0059] Embodiment 1: Preparation and characterization of supported nanometer nickel-based catalyst

[0060] The supported nano-nickel-based catalyst of the present invention is prepared by co-precipitation method, and the active metal nickel and the metal salt of the auxiliary agent are weighed in proportion at room temperature, and deionized water is added to prepare a catalyst with a total concentration of the active metal and the auxiliary agent salt of 0.1mol / L. Solution A; prepare NaOH concentration of 4mol / L, Na 2 CO 3 Concentration is the mixed alkali B of 1mol / L; Add the metal salt of carrier or commercially available oxide powder or colloid particle in proportion in reaction tank, add deionized water (addition amount is carrier metal salt or commercially available oxide powder or colloid 10 times the size of the particles) fully stir and mix evenly, then add salt solution A and alkali solution B dropwise to the reaction tank at the same time under rapid stirring, kee...

Embodiment 2

[0065] The preparation process and composition of the catalyst were the same as those of Catalyst 1, except that the concentration of metal salt solution A was 0.5moL / L, the catalyst was aged at 100°C for 2h, washed and dried, then calcined at 800°C for 2h, and reduced and activated at 750°C for 2h to obtain Catalyst 8. XRD characterization results show that the grain size of the reduction-activated catalyst is 6.2nm;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com