Glue overflow treatment method in non-illuminated area and water glue process using this method

A treatment method, non-illumination technology, applied in the direction of chemical instruments and methods, layered products, lamination auxiliary operations, etc., can solve the problems of cumbersome operation, low efficiency of side curing process, unsatisfactory curing effect, etc., to save investment, The effect of simplifying production operation mode and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only parts related to the present invention are shown in the drawings but not all content.

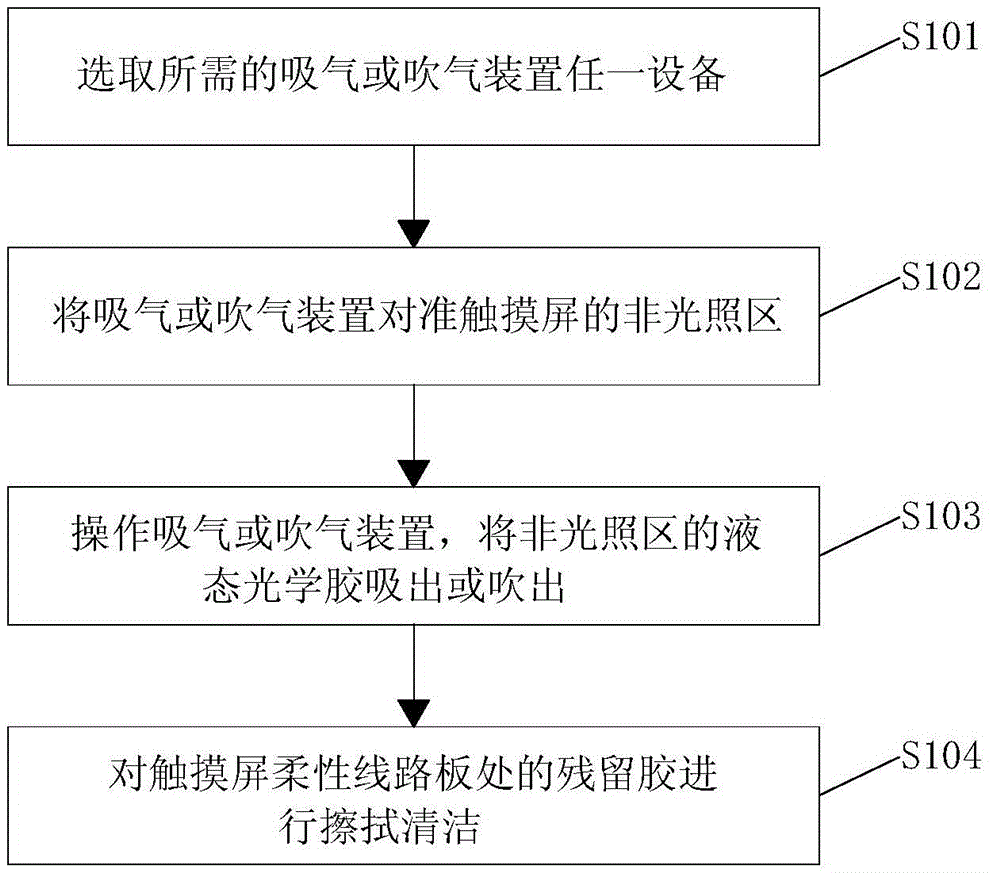

[0015] Please refer to figure 1 As shown, the non-illuminated area overflow glue treatment method in this embodiment specifically includes the following steps:

[0016] Step S101, select any one of the required suction or blowing devices. In this embodiment, the blowing device is an air gun.

[0017] Step S102, aiming the suction or blowing device at the non-illuminated area of the touch screen.

[0018] Step S103, operate the suction or blowing device to suck or blow out the liquid optical adhesive in the non-illuminated area.

[0019] It should ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com