Preparation method of large-size complex-shape high-transmittance lanthanum gadolinium zirconate transparent ceramics

A technology of lanthanum gadolinium zirconate and complex shape, which is applied to the preparation of lanthanum gadolinium zirconate transparent ceramics with large size and complex shape and high transmittance, and the preparation of transparent ceramic materials, and can solve the problem of large-scale and complex shape preparation in large quantities. The problems of lanthanum gadolinium zirconate transparent ceramics, small size and fixed shape samples, difficulty in large size and complex shape, etc., achieve the effect of easy industrialized mass production, environmentally friendly and non-toxic additives, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

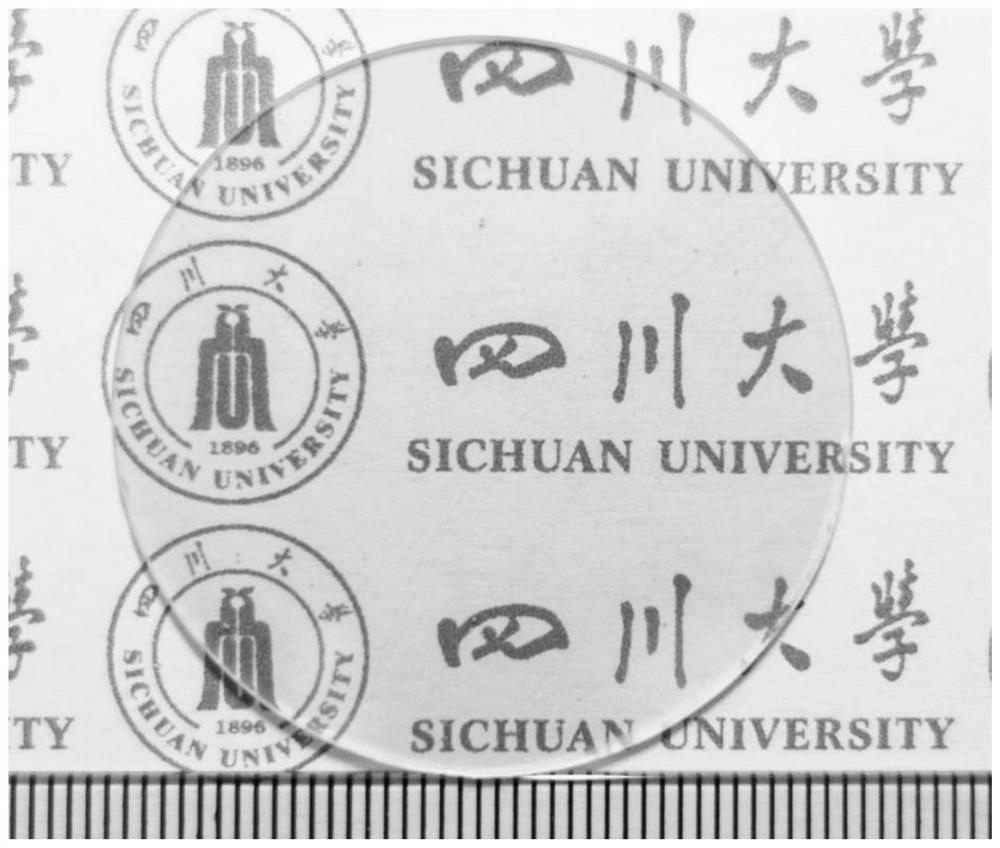

[0039] A large size and complex shape with high transmittance La 0.4 Gd 1.6 Zr 2 o 7 The preparation method of transparent ceramics comprises the following steps:

[0040] (1) Powder preparation: Add the raw materials zirconia, lanthanum oxide and gadolinium oxide powder into ethanol in a molar ratio of 4:0.6:1.4 and mix them evenly; mill the mixed solution with a 2mm ball mill whose mass is 25 times that of the raw material powders Put the balls together in a planetary ball mill at 250rpm for 24h, then place them in a drying oven and dry them at 60°C for 20h; after they are completely dry, grind the obtained solid particles and sieve them in a 200-mesh plastic screen, and then put them in a muffle furnace Calcined at 900°C for 3 hours in a medium air environment to obtain the precursor powder.

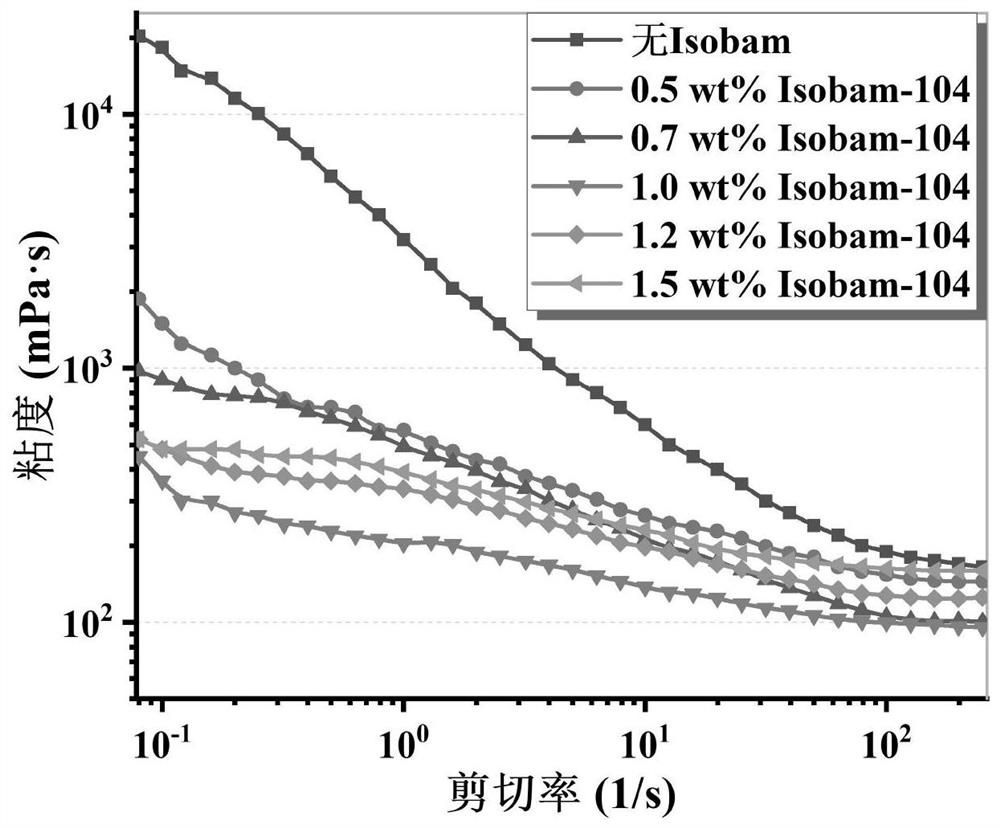

[0041] (2) Slurry preparation: the precursor powder of step (1) is mixed with isobutylene maleic anhydride copolymer (Isobam), ammonium citrate (TAC) and deionized water according...

Embodiment 2

[0046] A LaGdZr with large size and complex shape with high transmittance 2 o 7 The preparation method of transparent ceramics comprises the following steps:

[0047] (1) Powder preparation: Add zirconia, lanthanum oxide and gadolinium oxide powders into ethanol in a molar ratio of 4:1:1 and mix them evenly; mill the solution after mixing with a 2mm ball mill whose mass is 27 times that of the raw material powders Put the balls together in a planetary ball mill at 250rpm for 24h, then place them in a drying oven and dry them at 60°C for 20h; after they are completely dry, grind the obtained solid particles and sieve them in a 200-mesh plastic screen, and then put them in a muffle furnace Calcined at 900°C for 2 hours in a medium air environment to obtain the precursor powder.

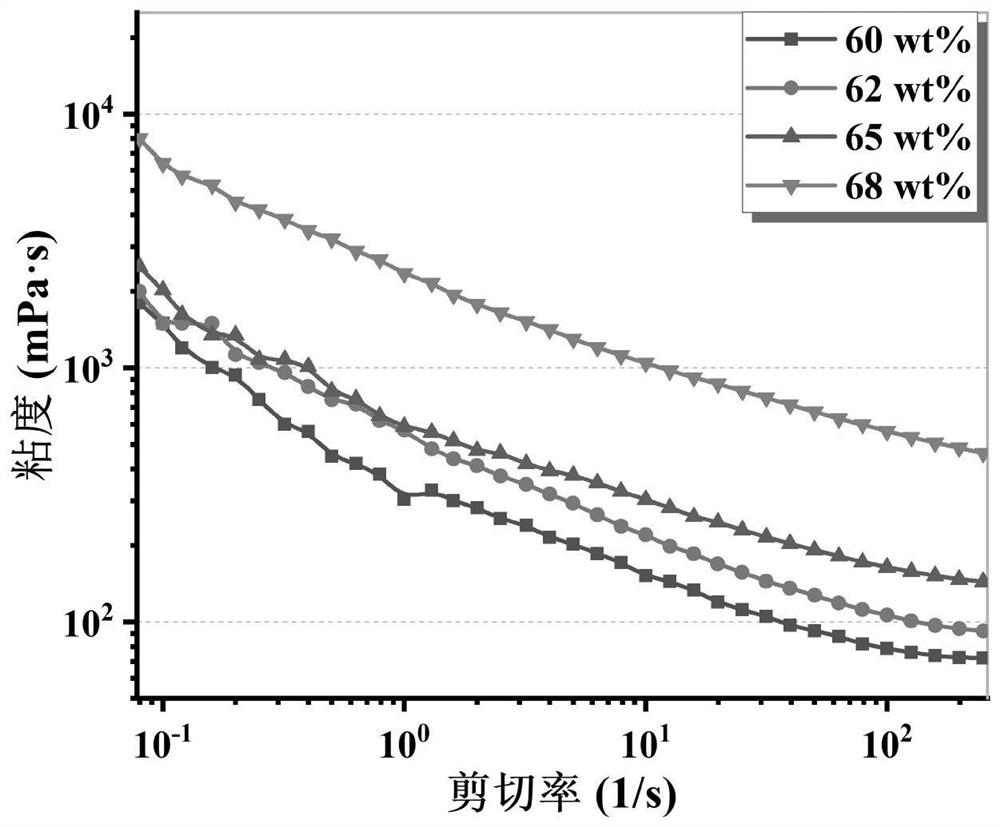

[0048] (2) Slurry preparation: the precursor powder of step (1) and isobutylene maleic anhydride copolymer (Isobam), ammonium citrate (TAC) and deionized water are in the mass fraction 65wt% in the sl...

Embodiment 3

[0053] A LaGdZr with large size and complex shape with high transmittance 2 o7 The preparation method of transparent ceramics comprises the following steps:

[0054] (1) Powder preparation: Add zirconia, lanthanum oxide and gadolinium oxide powders into ethanol in a molar ratio of 4:1:1 and mix them evenly; mill the solution after mixing with a 2mm ball mill whose mass is 27 times that of the raw material powders Put the balls together in a planetary ball mill at 250rpm for 24h, then place them in a drying oven and dry them at 60°C for 20h; after they are completely dry, grind the obtained solid particles and sieve them in a 200-mesh plastic screen, and then put them in a muffle furnace Calcined at 900°C for 2 hours in a medium air environment to obtain the precursor powder.

[0055] (2) Slurry preparation: the precursor powder of step (1) and isobutylene maleic anhydride copolymer (Isobam), ammonium citrate (TAC) and deionized water are pressed in the mass fraction of slurry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com