Systems for collecting and recycling winding waste

A waste and winding technology, which is applied in thin material processing, transportation and packaging, textiles and papermaking, etc., can solve the problems of collecting dust and fluff, co-discharging, and not disclosing cyclones, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

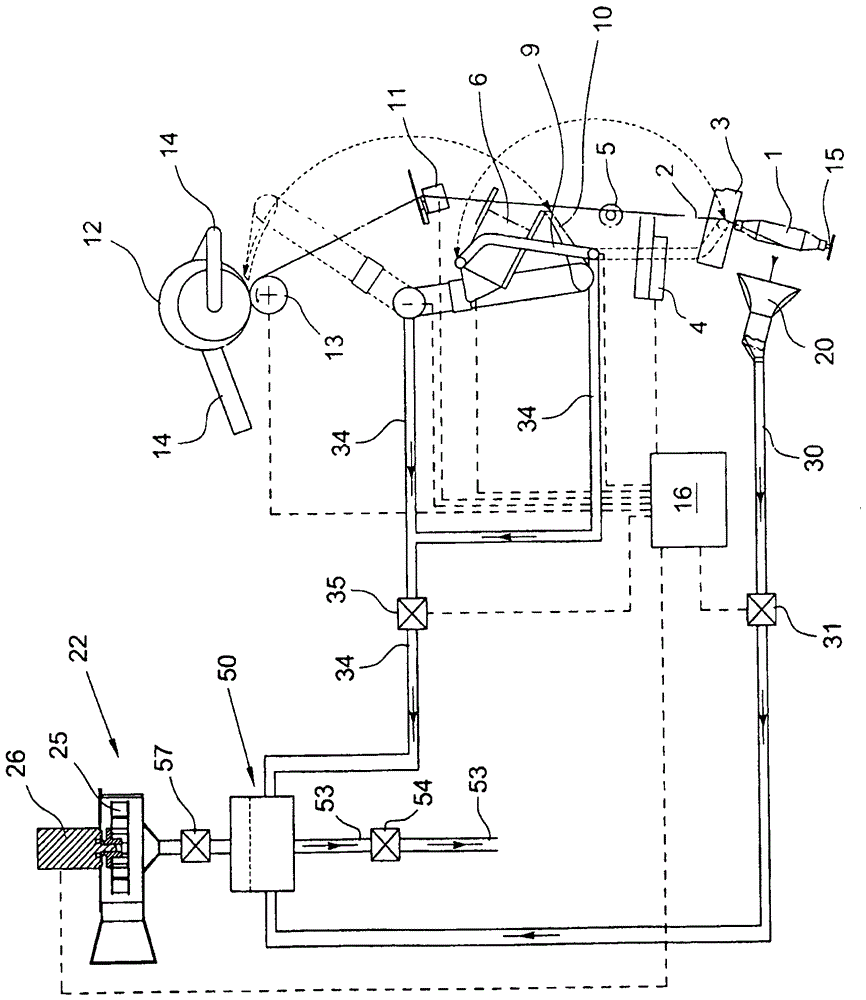

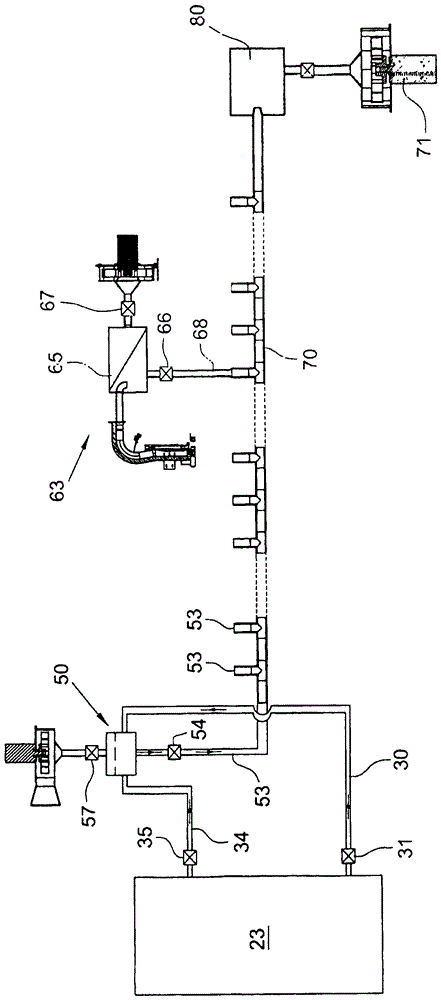

[0025] According to the present invention, the two tubes 30 and 34 of each winding station are connected to a common filter 50 used for each winding station individually, the filter 50 having the function of holding the material picked up and transported by suction In particular, the filter 50 maintains the "dust removal" impurities collected during the winding operation and the suction by the aspirator 22 when connected to the nozzles 9 and 10 and actuated under high negative pressure when the winding is interrupted. Suck both the removed yarn segments (so-called "fluff").

[0026] In each winding station, the individual filter 50 may be equipped with a single fine-mesh filtering section that retains all substances: impurities and fluff.

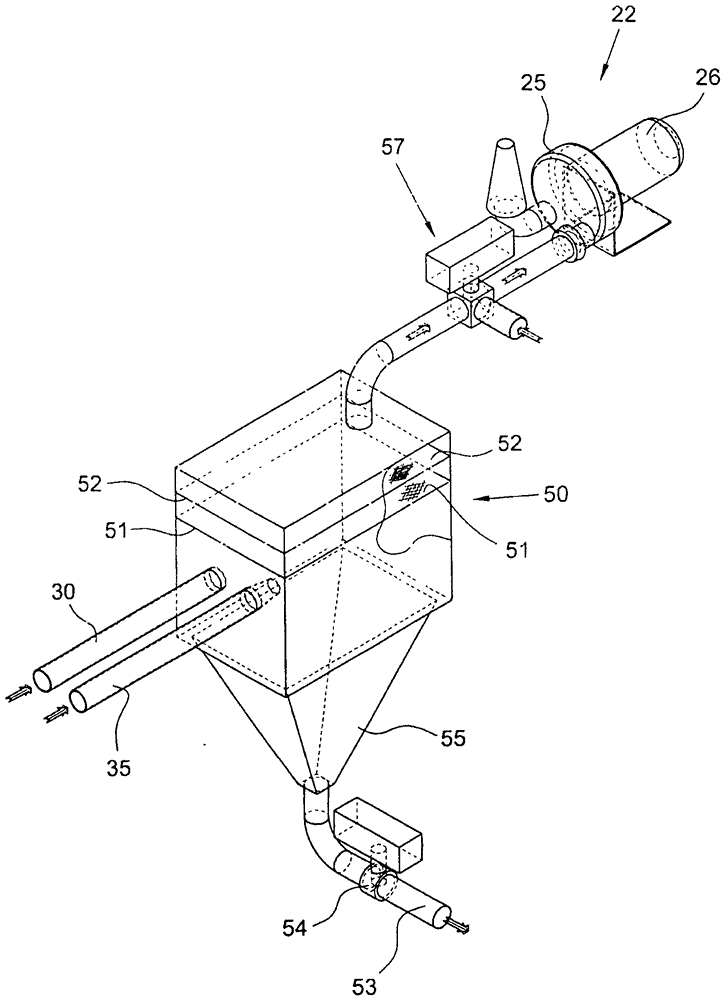

[0027] According to a preferred embodiment of the present invention, in the axial side view figure 2 As shown in the details, the single filter 50 includes two filter chambers connected in series, and includes a funnel 55 for collecting separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com