Anti-failure brake master valve

A brake master valve, anti-failure technology, applied in the direction of brakes, brake components, brake safety systems, etc., can solve the problem of not being able to give a timely and reasonable degree of power, poor emergency efficiency of traditional braking technology, loss of speed control and Parking and other problems, to achieve the effect of improving poor braking, strong social and economic benefits, and low loading costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

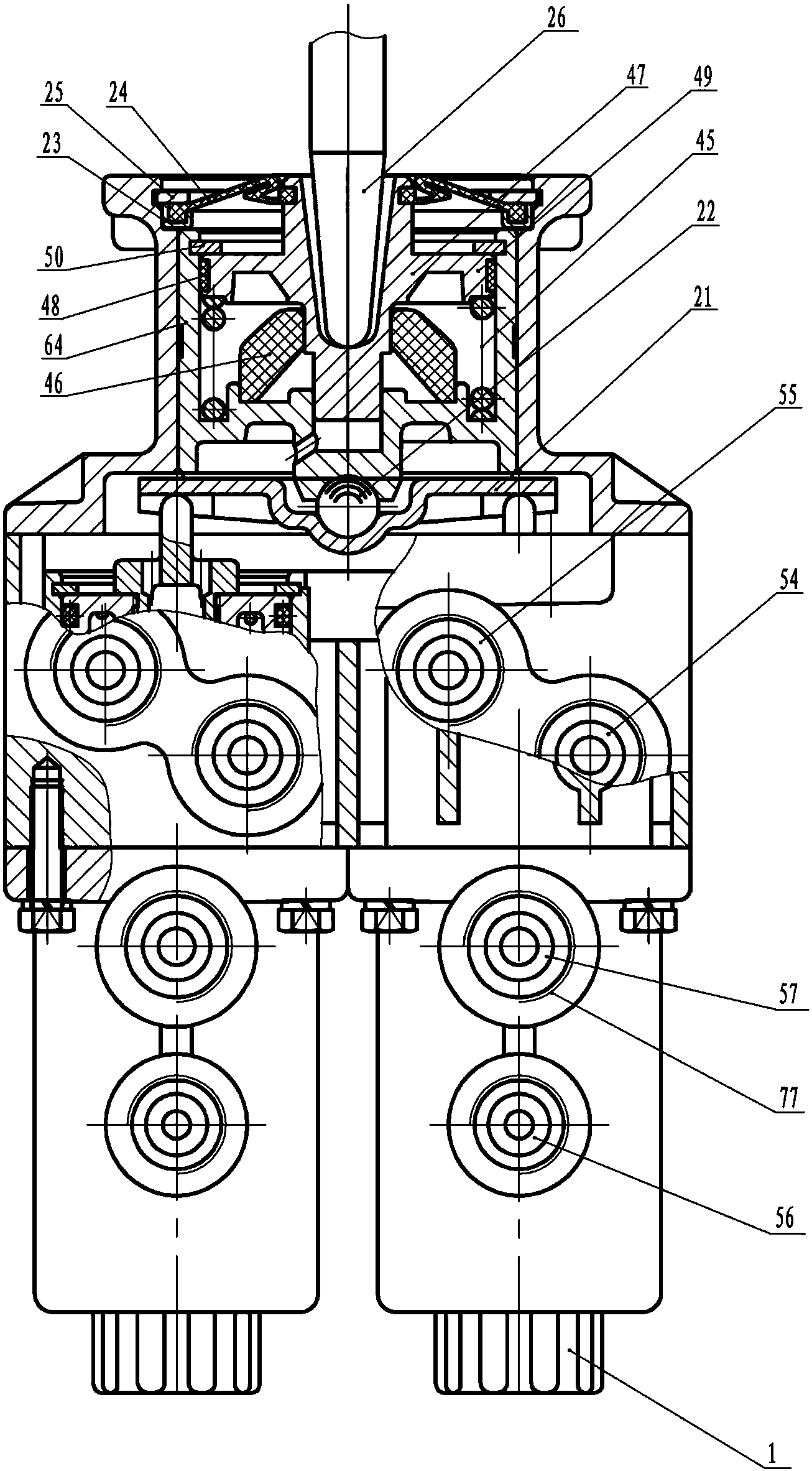

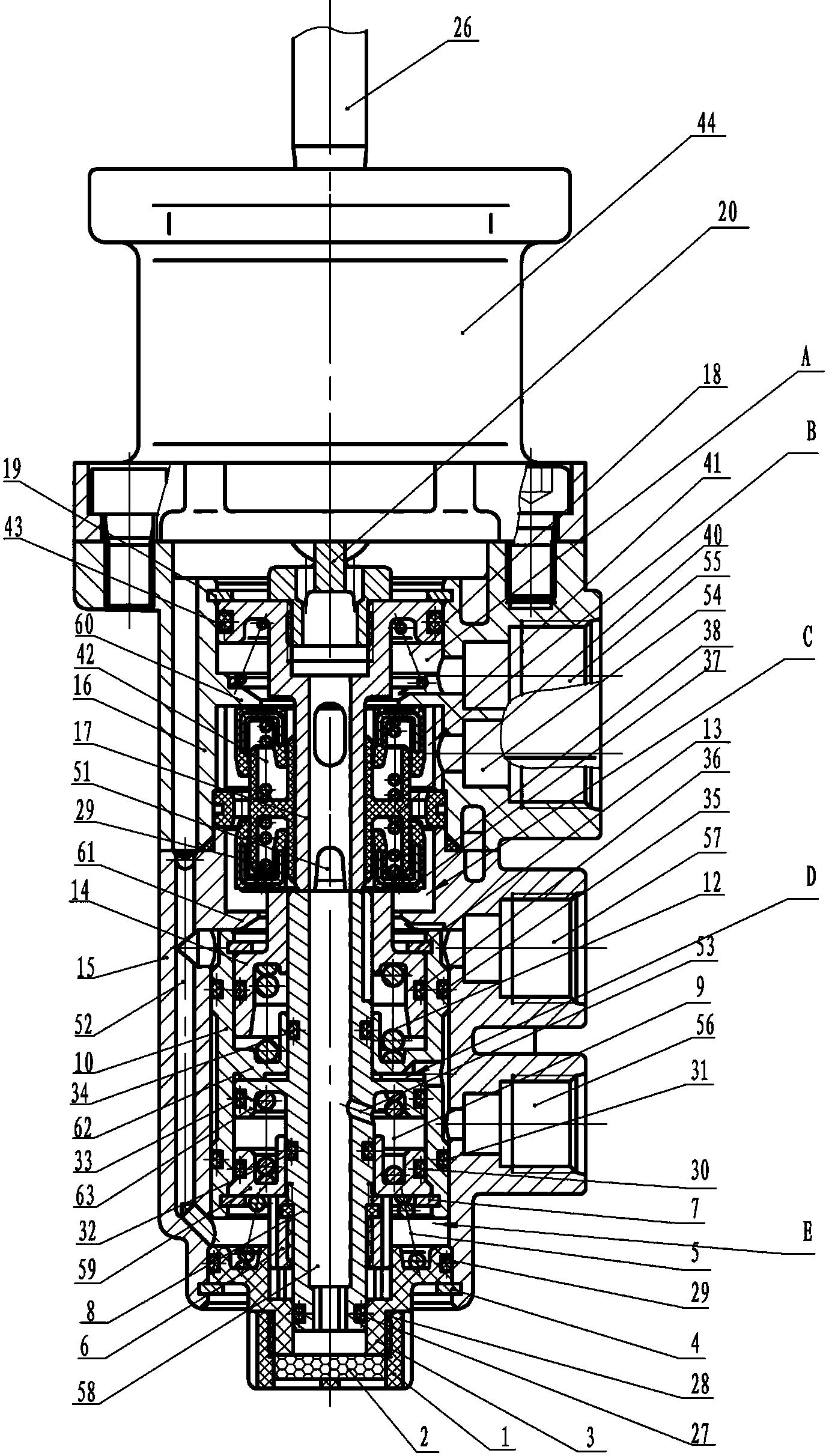

[0024] Embodiment 1: see figure 1 and figure 2 , The anti-failure master brake valve includes an upper valve body 44 , a middle valve body 16 and a lower valve body 15 which are sealed and connected sequentially from top to bottom.

[0025] figure 1 In the schematic diagram of the cross-sectional structure of the upper valve body, the upper valve body 44 is fitted with a valve seat 64, the valve seat 64 has a bottom plate, the center of the bottom plate protrudes downward, the lower part of the protrusion is the top, and the upper part of the protrusion is a groove. Vents are arranged on one side of the groove. The inner sealing sleeve of the upper end of the valve seat 64 is provided with a push rod seat 47, and a return spring 45 is connected between the peripheral edge of the push rod seat 47 and the valve seat bottom plate; In the bottom plate groove; the center of the upper end of the ejector rod seat 47 is provided with a ejector rod groove, and the ejector rod groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com