Device for liquefying and purifying natural gas

A technology of natural gas and gas-liquid separator, which is applied in the field of natural gas purification and liquefaction, can solve the problems of large area, large investment, large equipment investment, etc., and achieves small area, low investment, and large promotion and application value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

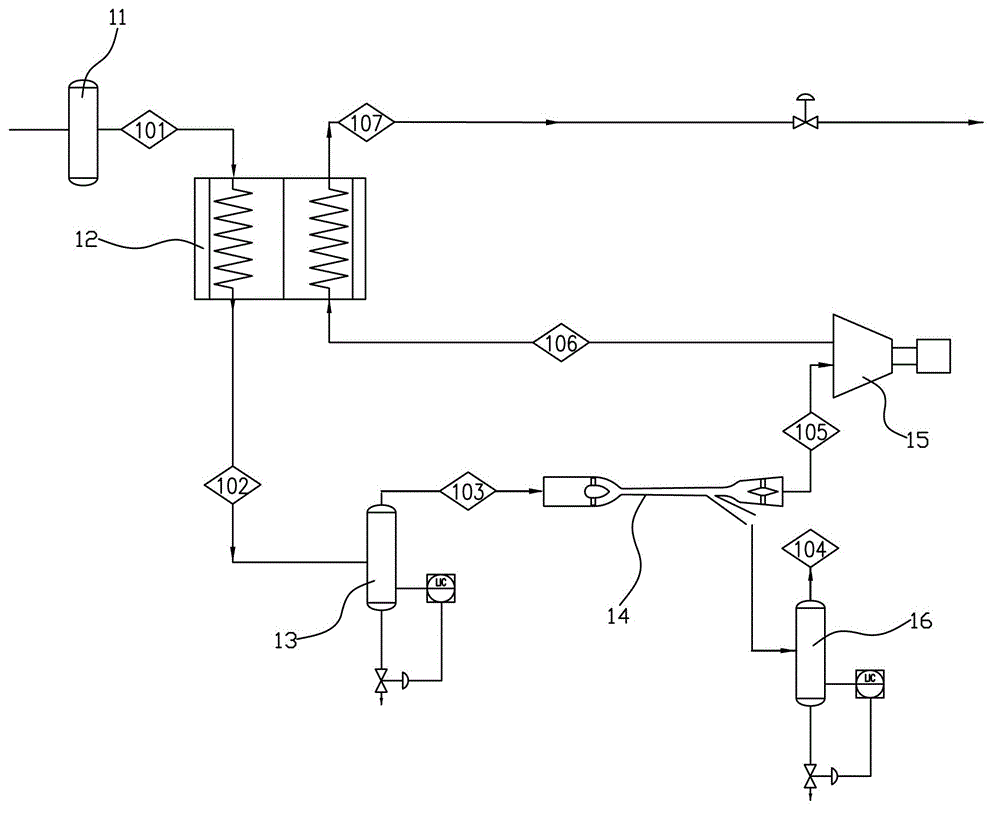

[0024] Such as figure 1 , 2 As shown, the device for liquefying and purifying natural gas provided by Embodiment 1 of the present invention includes a dehydrator 11, a heat exchanger 12, a first gas-liquid separator 13, a supersonic condenser 14, and an expansion refrigeration device 15 connected in sequence. The output end of equipment 15 communicates with the input end of heat exchanger 12;

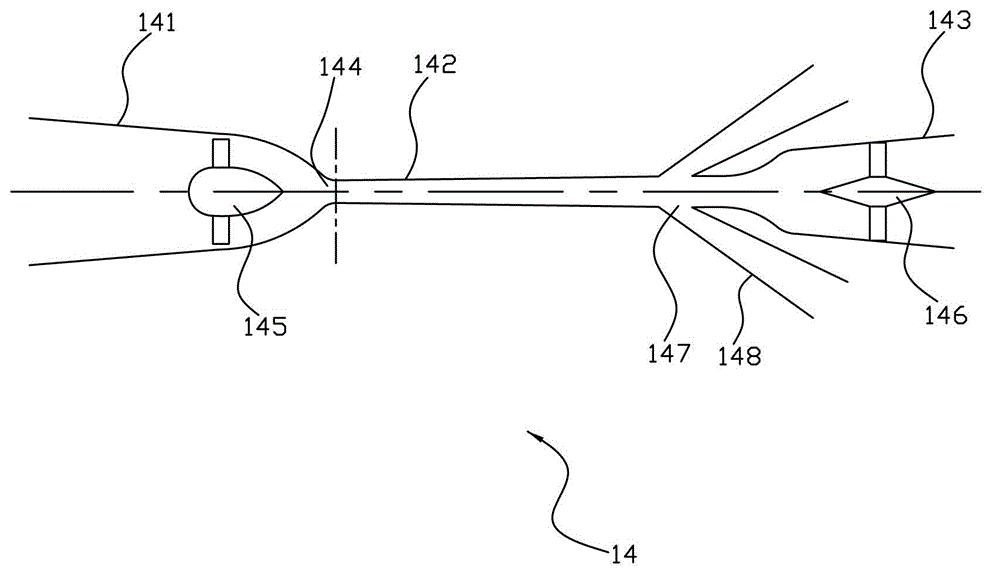

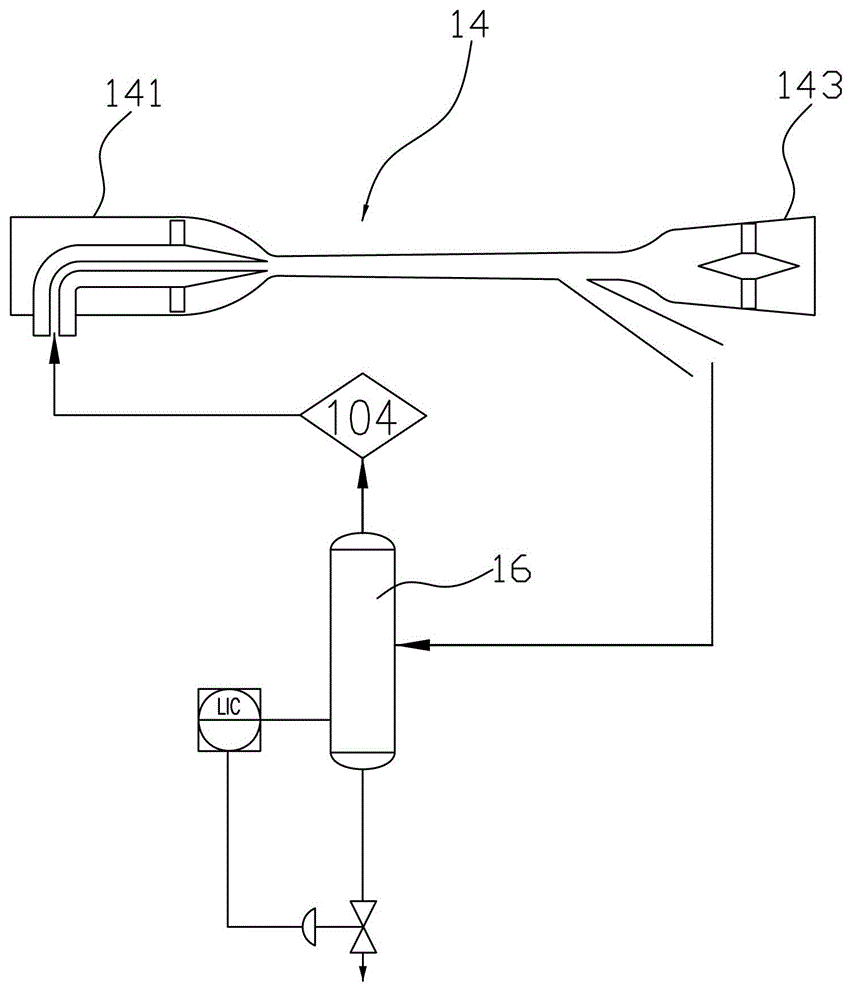

[0025] Wherein, the supersonic condenser 14 includes a constriction tube 141, a supersonic condenser tube 142 and a diffuser tube 143 which are connected coaxially in sequence from left to right. Throat 144, the supersonic condenser tube 142 extends from the narrow throat 144 from left to right and the cross-section gradually becomes larger, the cross-section of the diffuser pipe 143 gradually becomes larger from left to right, and a rotating mechanism 145 is arranged in the shrinkage pipe 141, and the diffuser A deflector 146 is provided in the pipe 143 , and at least one separation ...

Embodiment 2

[0035] Such as Figure 4 , 5 As shown, the device for liquefying and purifying natural gas provided by Embodiment 2 of the present invention includes a heat exchanger 22, a first gas-liquid separator 23, a supersonic condenser 24 and an expansion refrigeration device 25 connected in sequence, and the output of the expansion refrigeration device 25 is The end communicates with the input end of the heat exchanger 22.

[0036]Wherein, the supersonic condenser 24 includes a constriction tube 241, a supersonic condensing tube 242 and a diffuser tube 243 which are connected coaxially in sequence from left to right. Throat 244, supersonic condensing pipe 242 extends from left to right from narrow throat 244 and the cross section becomes larger gradually, and the cross section of diffuser pipe 243 gradually becomes larger from left to right. A deflector 246 is provided in the pipe 243 , and at least one separation outlet 247 is opened on the supersonic condenser pipe 242 , the separ...

Embodiment 3

[0043] Such as Figure 7 , 8 As shown, the device for liquefying and purifying natural gas provided by Embodiment 3 of the present invention includes a heat exchanger 32 , a first gas-liquid separator 33 and a supersonic condenser 34 connected in sequence.

[0044] Wherein, the supersonic condenser 34 includes a constriction tube 341, a supersonic condenser tube 342 and a diffuser tube 343 which are connected coaxially in sequence from left to right. Throat 344, supersonic condenser tube 342 extends from left to right from narrow throat 344 and the cross section becomes larger gradually, and the cross section of diffuser pipe 343 gradually becomes larger from left to right, and a rotating mechanism 345 is arranged in shrinkage pipe 341, and the diffuser A deflector 346 is provided in the pipe 343, and at least one separation outlet 347 is provided on the supersonic condenser pipe 342, and the separation outlet 347 is connected with a separation pipe 348, and the separation pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com