Broken yarn detection method based on video signal processing

A detection method and yarn breakage detection technology, which is applied in textiles, textiles, papermaking, looms, etc., and can solve problems such as false detection and detector influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

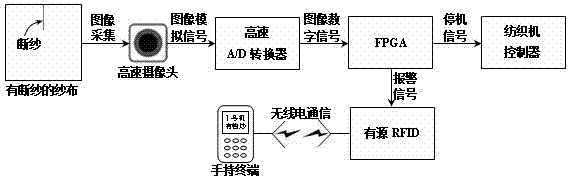

[0007] The gauze woven by the textile machine is generally a solid color (such as white). If there is no broken yarn, the gray value of the entire image collected by the camera is consistent. Once there is a broken yarn (usually a thread broken in the vertical direction), a certain The gray value of the image along the vertical axis is abnormal. This patent realizes broken yarn detection based on this principle.

[0008] Since the broken yarn detection has high requirements on real-time performance, and the loom will rotate when it is working, it is necessary to use a high-speed camera for image acquisition, otherwise it will easily cause ghosting and false detection. In order not to miss detection, the system must have high-speed data processing capabilities. Therefore, high-speed A / D converters are used to sample and analog-to-digital convert image signals, and FPGAs with fast running speed and strong parallel processing capabilities are used to directly process image in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com