Hydraulic actuation device for actuating positioning members in motor vehicle transmission

A technology for hydraulic transmissions, motor vehicles, applied in transmission control, fluid pressure actuation devices, elements with teeth, etc., can solve problems such as energy loss, spool valve leakage, occupation, etc., and achieve a higher level of fluid cleanliness. High, false activation prevention, compact size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example ;

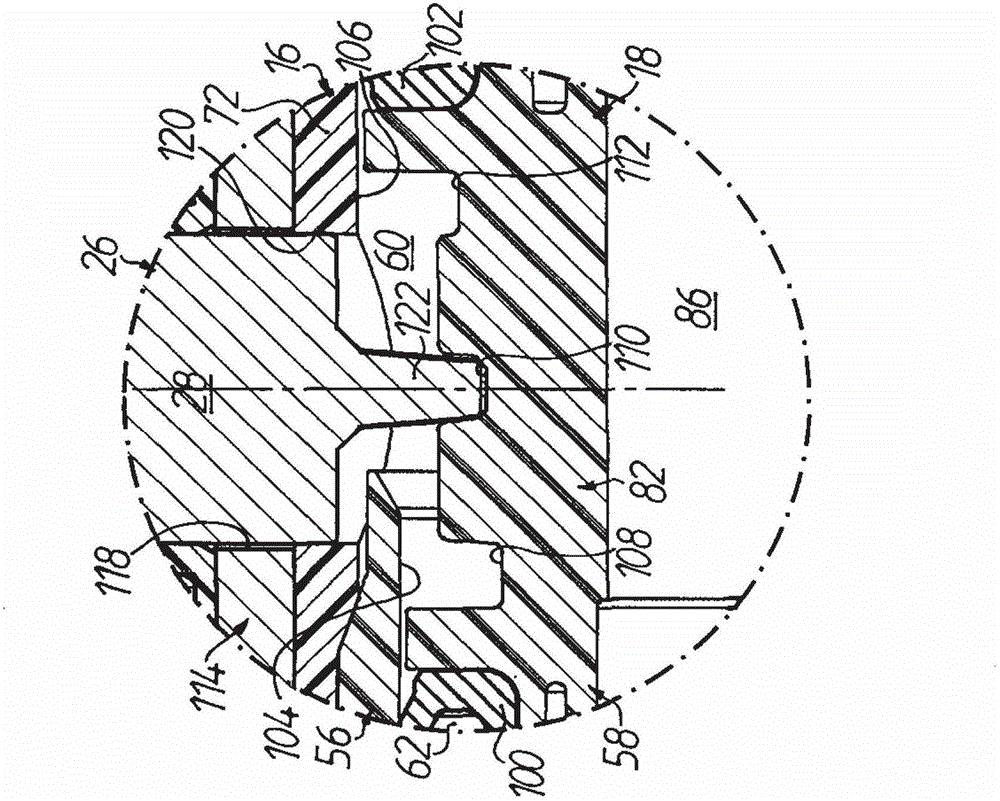

[0024] figure 2 shown as figure 1 Enlarged view of detail part II in , illustrating how the locking element of the stop device cooperates with the locking section on the piston of the piston-cylinder assembly. Radial groove formation of different groove depths;

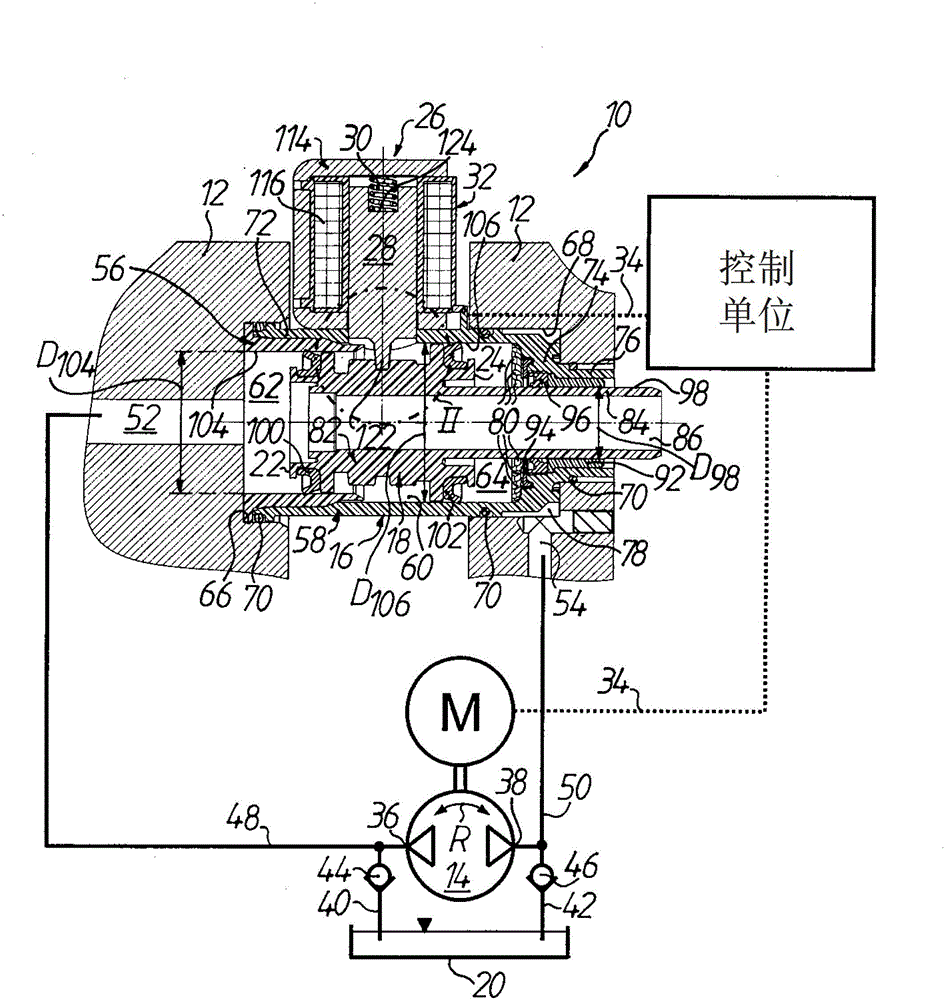

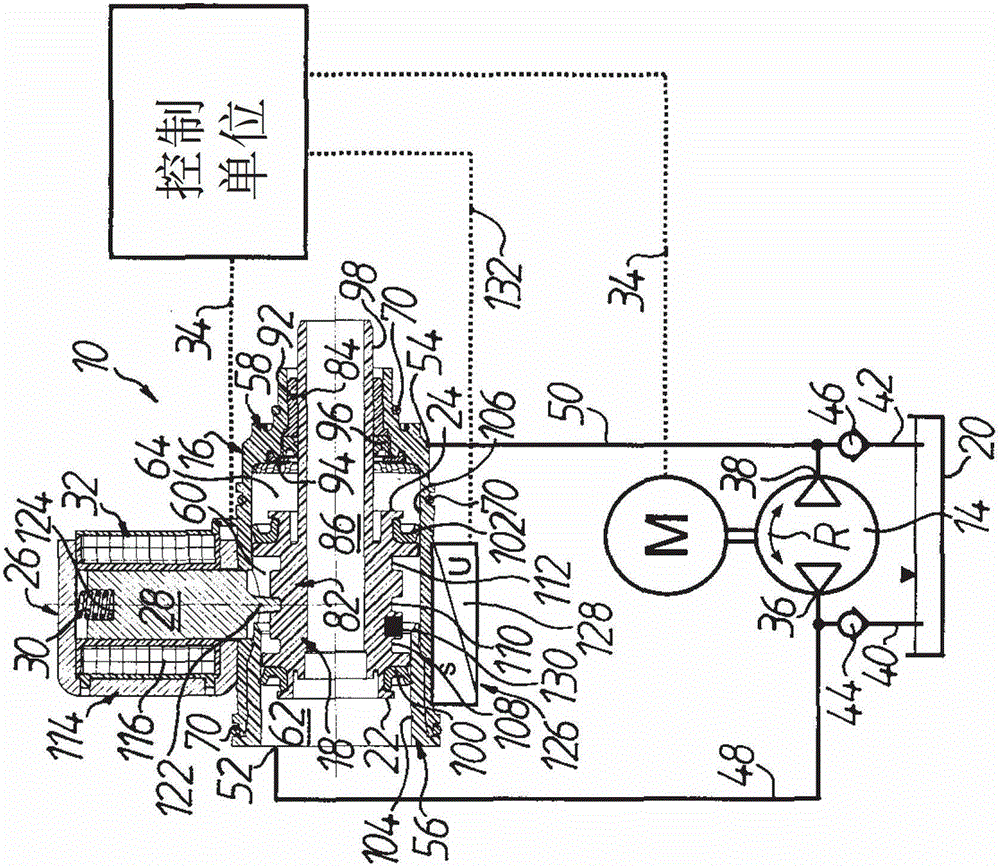

[0025] image 3 Shown is a circuit diagram of a variant of the hydraulic transmission according to the first embodiment, in which the radial grooves on the outer circumference of the pistons have the same depth, and sensor means for detecting the position of the pistons are additionally provided;

[0026] Figure 4 Shown is a circuit diagram of a hydraulic transmission for driving a plurality of positioning elements in a motor vehicle transmission, with a corresponding number of piston-cylinder assemblies hydraulically connected in parallel to a single pump, as according to Second embodiment of the present invention;

[0027] Figure 5 Shown is a circuit diagram of a hydraulic transmission with only one piston-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com