Anti-condensation system for groove type solar photo-thermal power generation

A trough solar and photothermal power generation technology is applied in the field of anti-condensation systems, which can solve the problems of heat dissipation and solidification of heat-conducting oil, and achieve the effects of preventing condensation, improving boiler efficiency and moderate price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

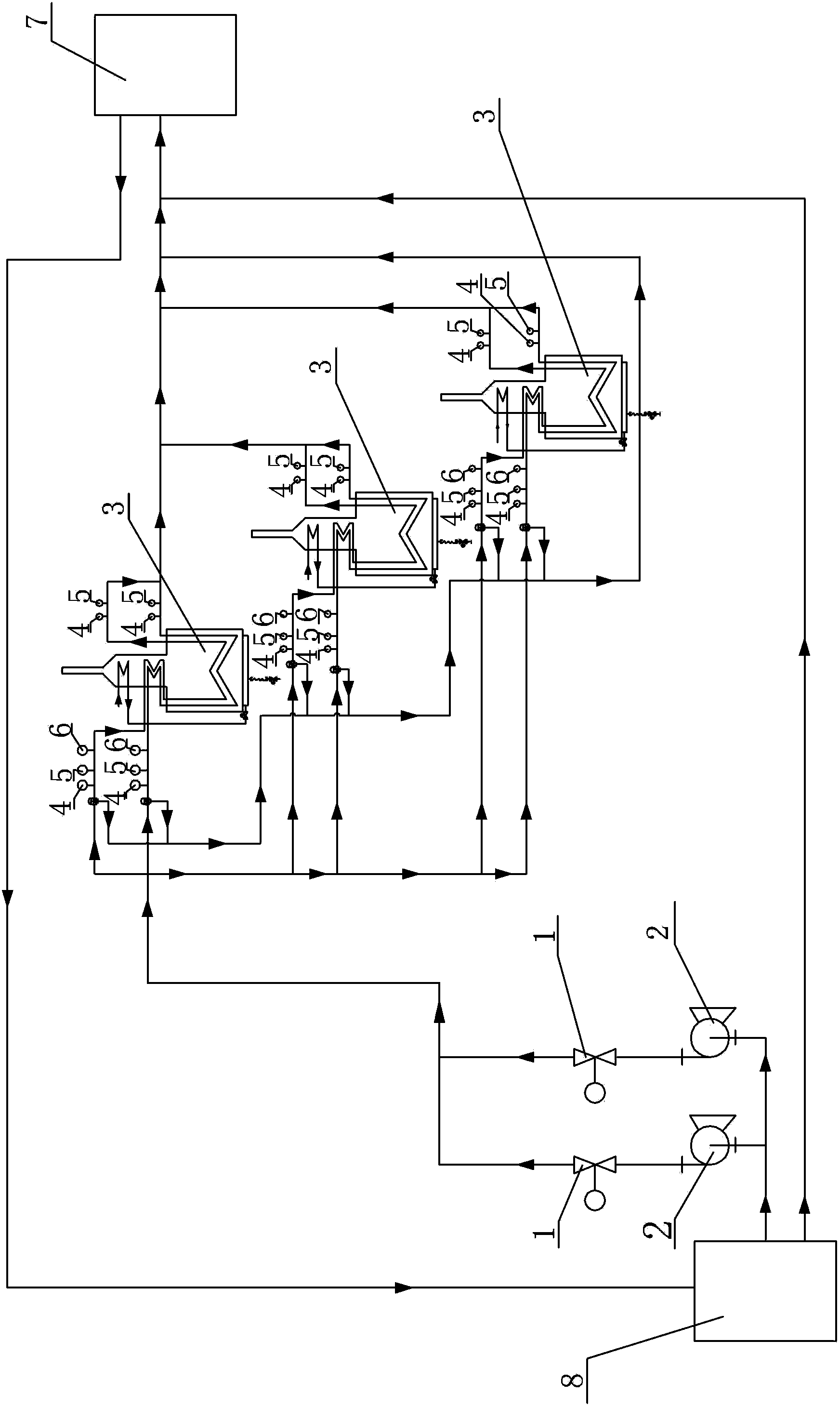

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment. In this embodiment, an anti-condensation system for trough solar thermal power generation includes at least two pump valve systems and at least three boilers 3, and each pump valve system includes a delivery pump 2 and a regulating valve. 1. The heat transfer oil input end of the transfer pump 2 in each set of the pump valve system is used to communicate with the heat transfer oil outlet port of the heat exchange system 8, and the heat transfer oil output of the transfer pump 2 in each set of the pump valve system end is connected with the heat transfer oil inlet port of the corresponding control valve 1, the heat transfer oil outlet port of the control valve 1 in each pump valve system is respectively connected with the heat transfer oil inlet port of each boiler 3, and the heat transfer oil outlet port of each boiler 3 The ends are respectively used to communicate with the mirror field 7 of t...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination figure 1 This embodiment will be described. The boiler 3 in this embodiment is a vertical gas boiler. With this setting, the system has high flexibility, and it is easier to control the flow in the tube, which can be used to compensate the inlet temperature of the mirror field. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination figure 1 This embodiment will be described. The control valves 1 in this embodiment are all electric control valves. With such a setting, the flexibility is high, and it is easier to control the flow in the pipe to meet the design requirements and actual needs. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com