Inward recess-proof capillary tube

A technology of capillary and anti-detachment groove, which is applied in the direction of fluid circulation arrangements, refrigeration components, refrigerators, etc., and can solve problems such as capillary tube wall invagination and capillary breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

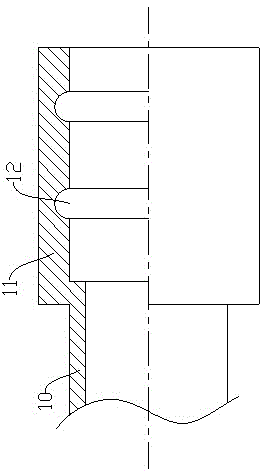

[0012] Examples, see figure 1 As shown: the anti-sag capillary tube includes a body 10, and an anti-falling groove 12 is provided on the inner side of the port of the body 10. In this way, when two capillary tubes are connected, they can be connected by putting the end of the capillary tube on the outside of one connecting short tube. Obviously, the anti-detachment groove 12 prevents the capillary from being disengaged from the connecting short tube.

[0013] Optimally, the cross-section of the anti-loosening groove 12 is arc-shaped. Such anti-loosening groove 12 is easy to prepare, for example, it can be formed by pressing after being supported by an abrasive tool.

[0014] Further, the port portion of the main body 10 is provided with an outer flaring opening 11 , and the anti-loosening groove 12 is located ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap