Panel switch installation structure, panel switch and installation method of panel switch

A panel switch and installation structure technology, applied in electrical switches, electrical components, circuits, etc., can solve the problems of the rear lugs falling off, the wiring cassette being troublesome, sinking into the wall, etc., to reduce the accuracy requirements, maintain the overall appearance, The effect of a good overall appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

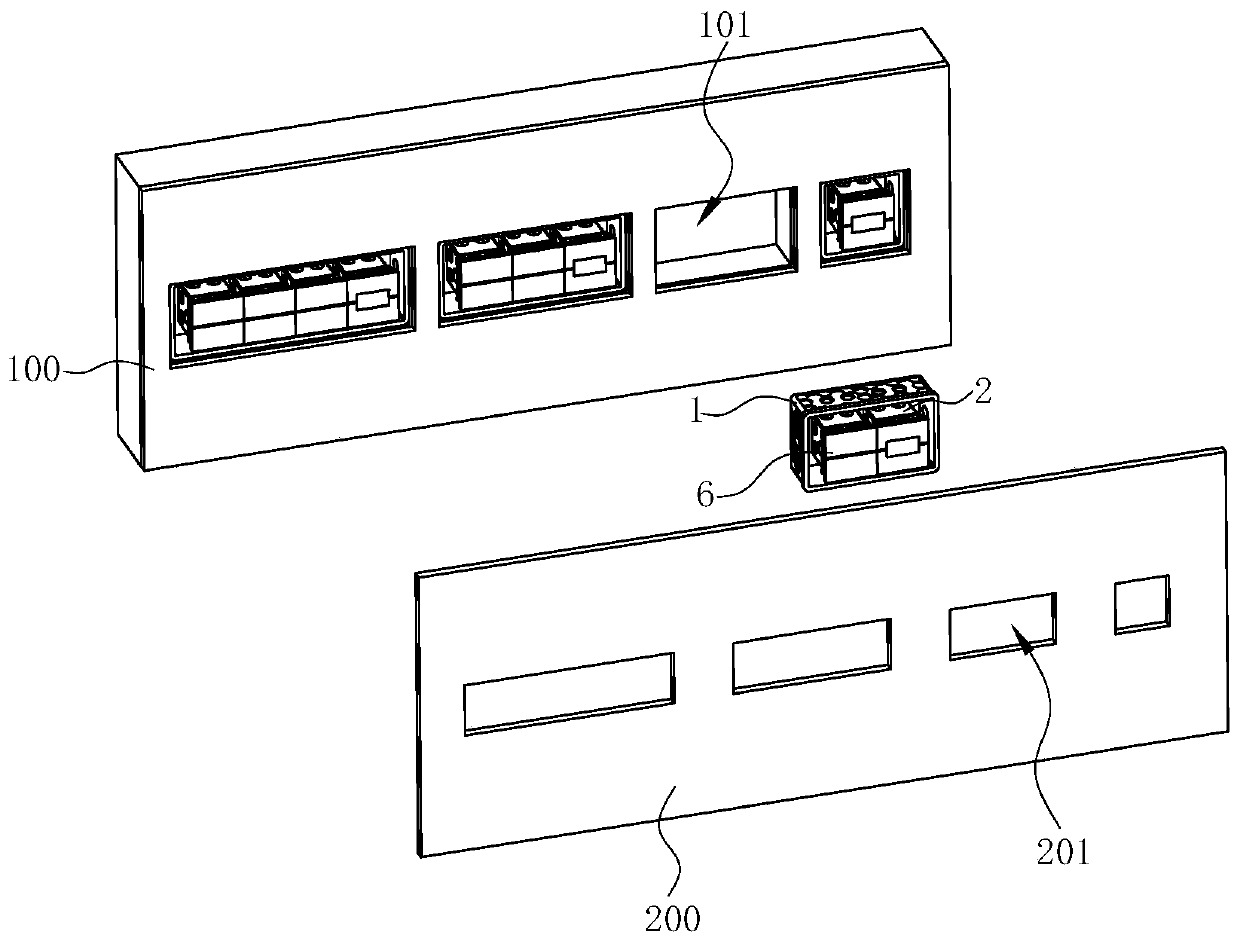

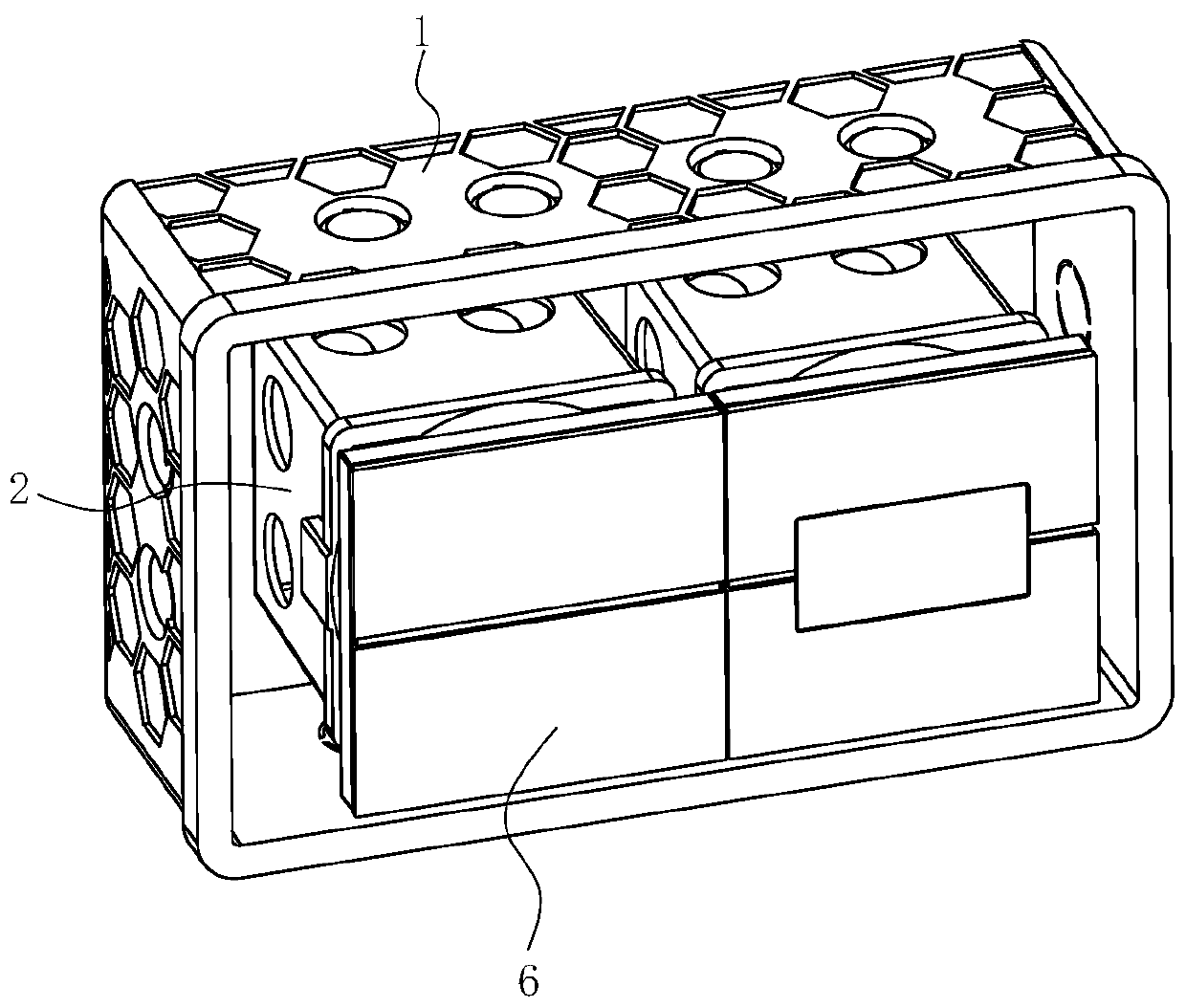

[0034] see image 3 , Figure 4 and Figure 6 , a panel switch, including a bottom box 1, a cassette 2, a spacer 3, a panel bracket 4, a panel base 5 and a panel 6. The above-mentioned bottom box 1, cassette 2 and spacer 3 constitute a panel switch installation structure.

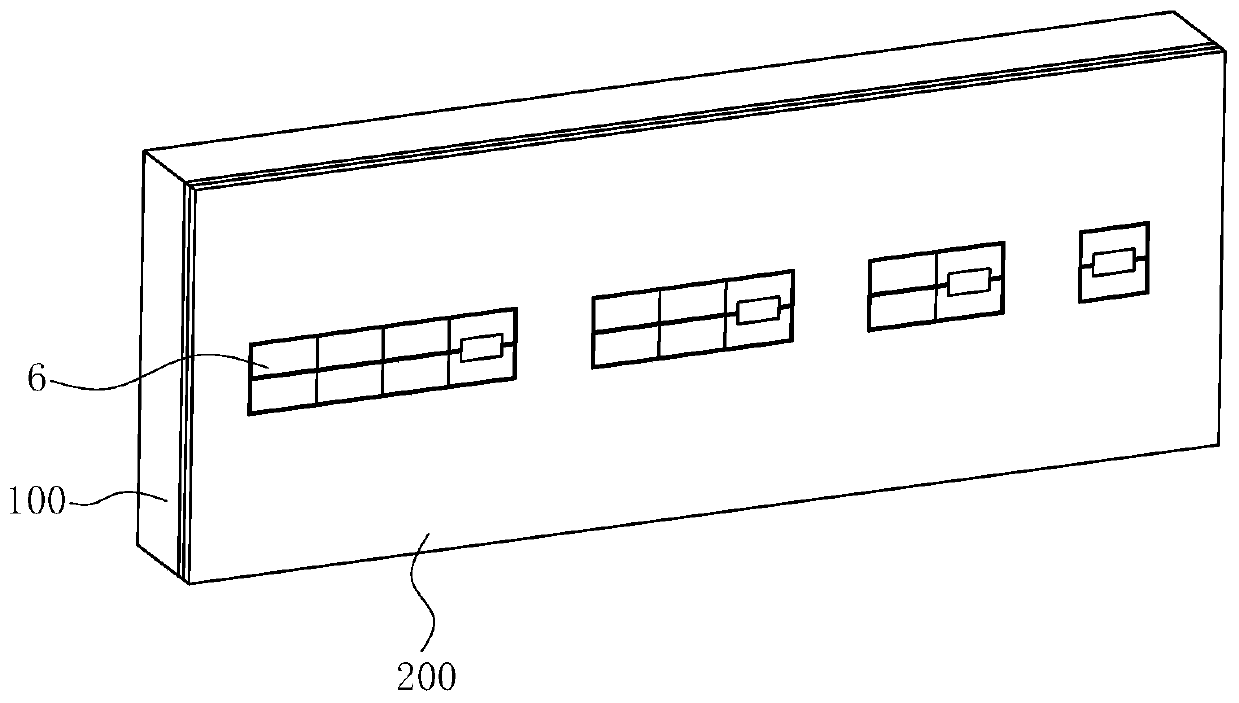

[0035] see Figure 1 ~ Figure 4 , the bottom box 1 is a hollow cuboid (including cube) structure, and its size can be selected according to the quantity and size of the panels 6 to be installed, such as figure 1 As shown, there are quadruple switches, triple switches, double switches, single switches, Figure 4The one shown in is a double switch, and different sizes can be made according to different needs. The bottom box 1 is in the shape of one side opening, including a first bottom surface 11 and four first side surfaces 12, the first bottom surface 11 is rectangular (including square), and the four first side surfaces 12 are arranged on the periphery of the first bottom surface 11, First through h...

Embodiment 2

[0052] see Figure 7 In this embodiment, the difference from the first embodiment above is that the shape of the spacer 3 is adapted to the outer peripheral shape of the accommodating cavity 53 of the panel base 5, and the side wall of the hollow hole 31 of the spacer 3 is formed with The protrusions 32 extending into the hollow hole 31 , preferably, the protrusions 32 are arranged on two opposite side walls of the hollow hole 31 , and each side wall is provided with two protrusions 32 . The protrusion 32 can clamp the panel base 5, so that the bonding area between the cushion block 3 and the panel base 5 is larger, so that after the panel bracket 4 and the cassette 2 are fixed by screws, the positions of the three are more stable.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap