Detonator blasting system based on electronic delay body

A delay body and electronic technology, applied in the direction of blasting, electric fuze, weapon accessories, etc., can solve the problems of system complexity and redundancy, lead pollution of chemical delay agents, etc., achieve the effect of maintaining simplicity and reliability, and eliminating chemical agent pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

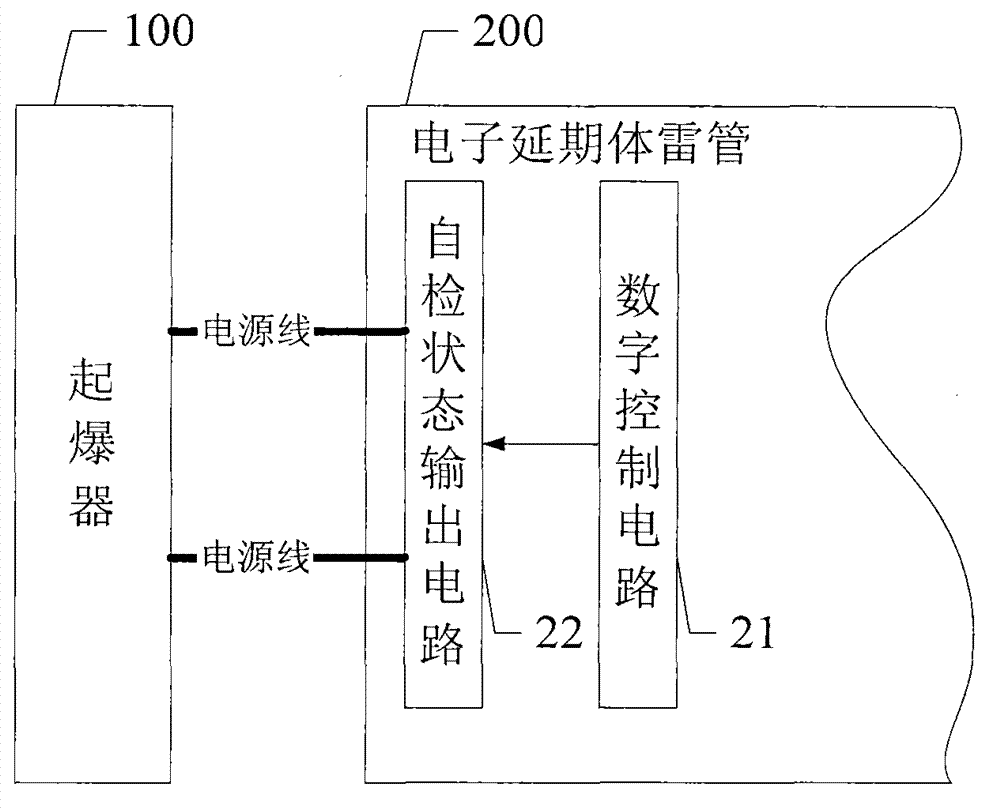

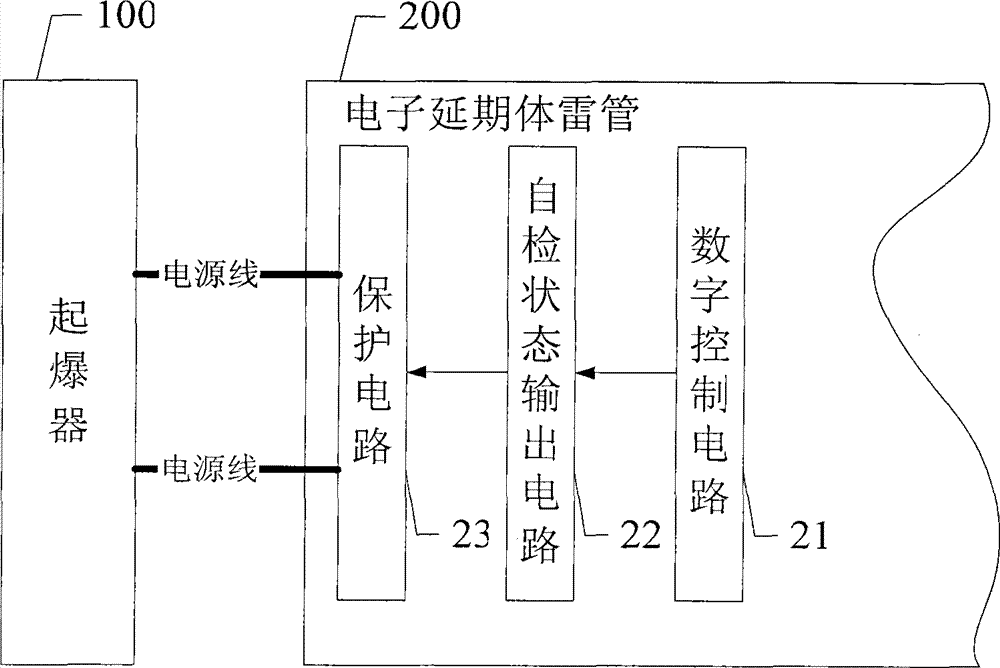

[0015] Such as figure 1 Shown is a schematic diagram of the composition of the detonator blasting system based on the electronic delay body of the present invention. The detonator blasting system based on electronic delay body includes a detonator 100 and an electronic delay body detonator 200 connected by a power line. During actual operation, each detonator 100 is connected to a plurality of electronic delay detonators 200 through networking. The electronic delay detonator 200 includes a digital control circuit 21 and a self-test status output circuit 22 .

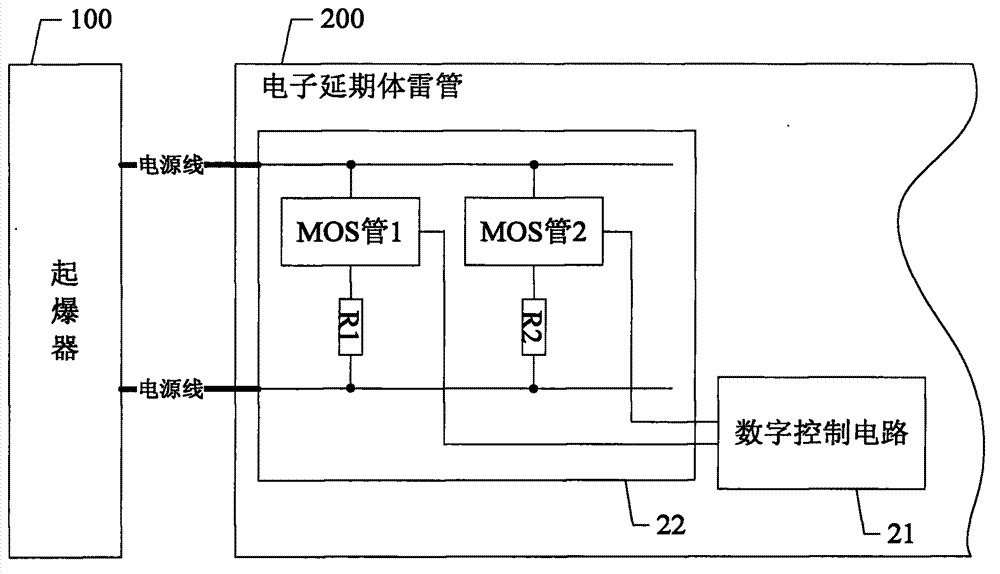

[0016] Such as figure 2 As shown, it is a schematic diagram of the composition of the self-test state output circuit and the connection relationship with the system of the present invention. The self-test state output circuit 22 is a component of the electronic delay detonator 200 , one end is connected to the detonator 100 through a power line, and the other end is connected to the digital control circuit 21 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com