Tension and compression-reversing coupling loading testing device for inspecting gas tube structure

A technology of loading a test device and an inflatable tube, which is applied in the direction of applying stable tension/pressure to test the strength of the material and the ductility of the test material to achieve the effect of reducing friction, wide application and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

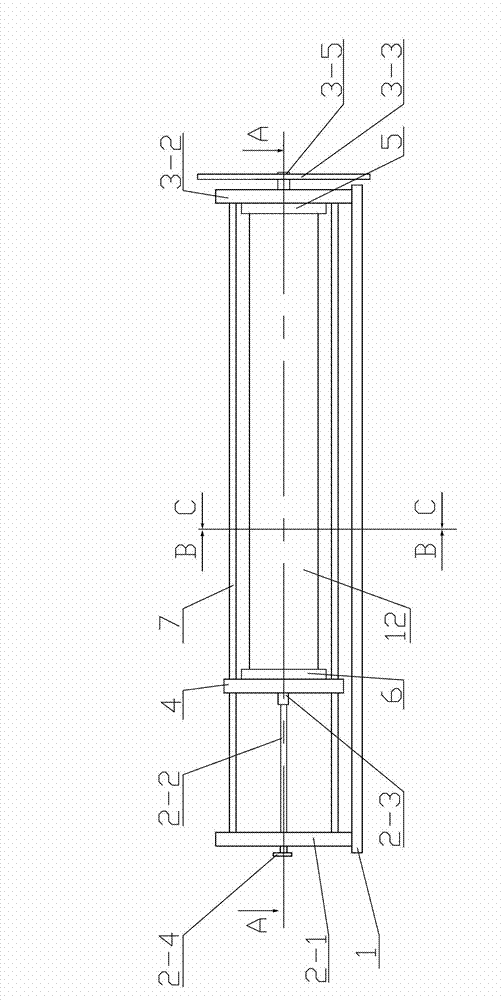

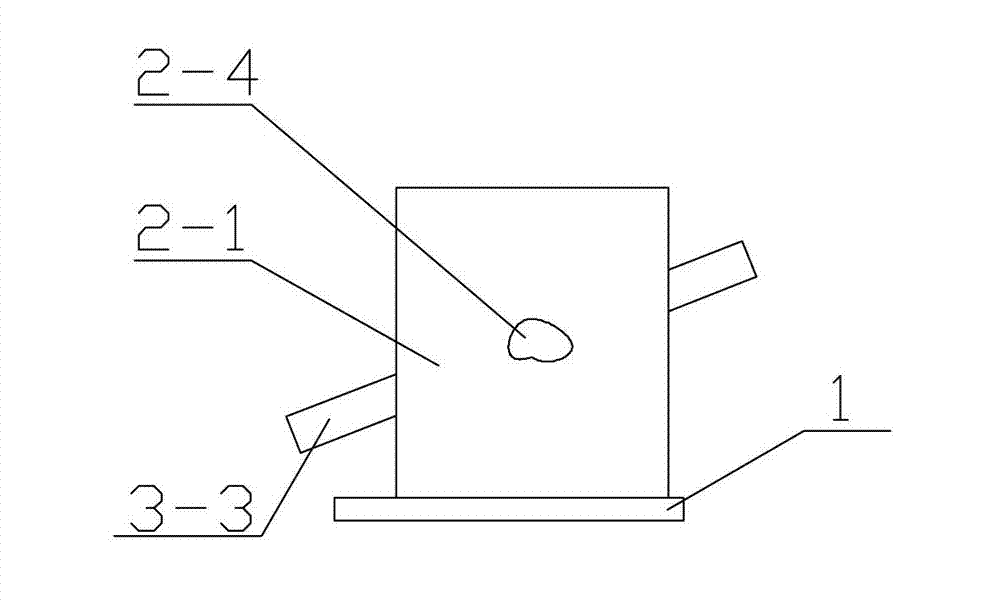

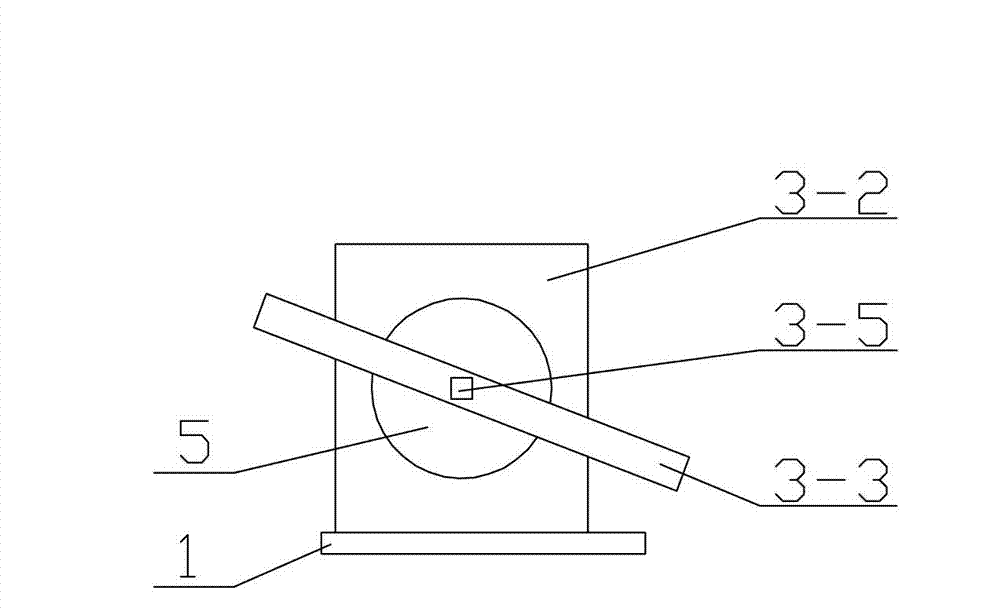

[0015] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 Describe this embodiment, the test device in this embodiment includes a fixed platform 1, a tension and compression loading system 2, a torsion loading system 3, a movable baffle 4, a first end cover 5, a second end cover 6 and four Support bar 7, the fixed platform 1 is set horizontally, the tension and compression loading system 2, the torsion loading system 3 and the movable baffle 4 are all arranged on the fixed platform 1, and the movable baffle 4 is vertically arranged on the tension and compression loading system 2 Between the torsion loading system 3, the tension and compression loading system 2 includes a tension and compression loading fixed baffle 2-1, a lead screw 2-2, a load cell 2-3 and a handle 2-4. 3 includes a torsion dial 3-1, a torsional loading fixed baffle 3-2, a torsional loading ro...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 To describe this embodiment, the torsion dial 3-1 in this embodiment is an annular dial, and a pointer 11 is provided at the midpoint of the top of the torsion loading fixed baffle 3-2. Install the ring dial on the inside of the torsional loading fixed baffle 3-2 (that is, the side of the inflation tube 12) and set it concentrically with the roller 3-4, and the ring dial and the first end cover rotate synchronously, and the pointer 11 is located at the torsion loading fixed At the center position of the top of the baffle plate 3-2, the twist angle of the inflatable tube 12 can be read by the position of the pointer 11 on the twist dial 3-1. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 To describe this embodiment, in this embodiment, the four third through holes 10 are all located at the four end corners of the movable baffle 4 . The third through hole 10 provided in this way can make the distance between the inflatable tube 12 and the support rod more reasonable, which is beneficial to the inflatable tube 12 to accurately obtain the data of its tension-compression-torsion coupling loading through the present invention. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com