Transformer

A transformer and heat sink technology, applied in the field of transformers, can solve problems such as poor power supply quality and no access to the third harmonic, and achieve the effects of improving external heat dissipation, reducing costs, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

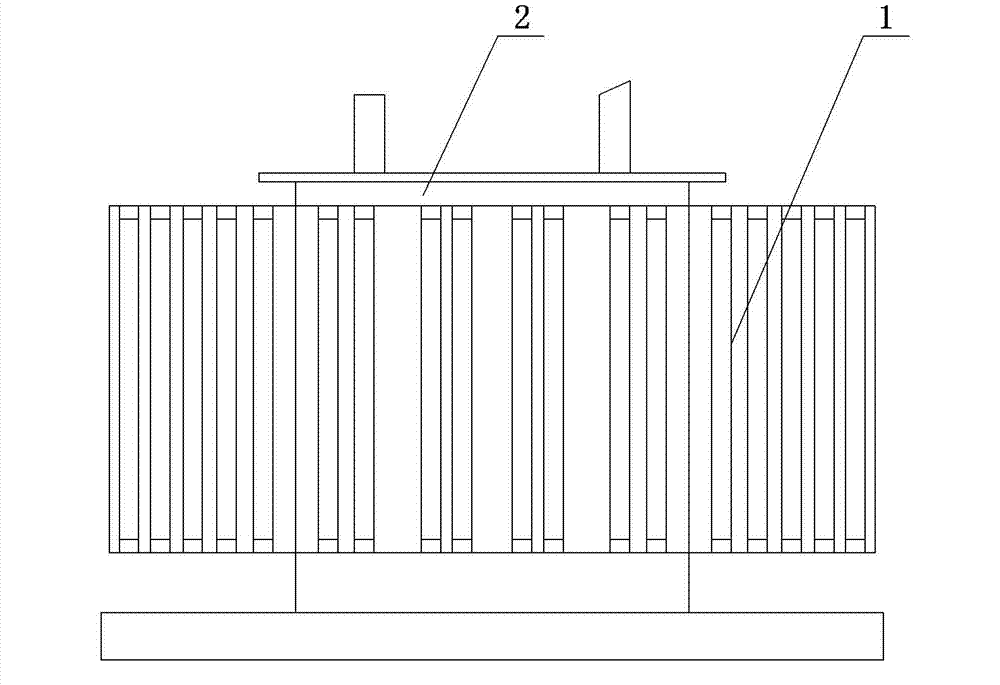

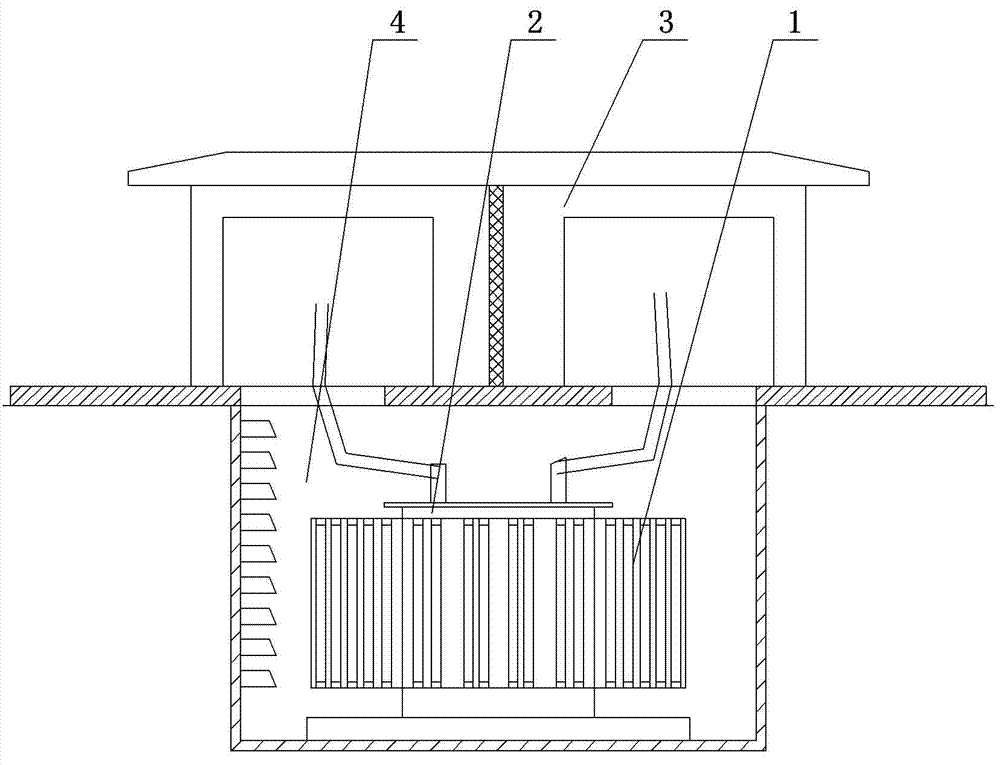

[0030] As shown in the figure, the present invention includes a transformer main body 2 and a radiator 1 surrounding the transformer main body 2. The transformer main body 2 is arranged in a box in the middle of the radiator 1. There is a main cavity between the inner wall of the box and the main body of the transformer, and the outer wall of the box and the main cavity. There is a cooling cavity between the inner walls of the radiator; transformer oil is arranged in the main cavity, and water is arranged in the cooling cavity.

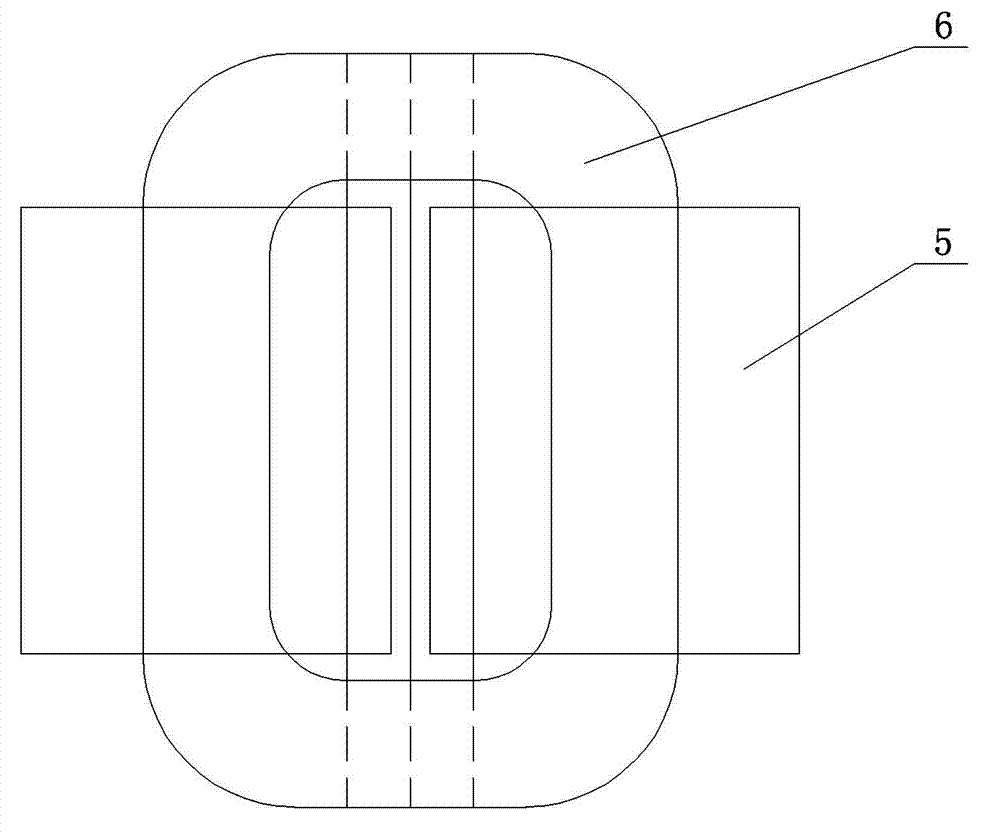

[0031] The main body of the transformer 2 adopts a three-phase three-dimensional wound core. The three-phase three-dimensional wound core adopts the D, yn11 connection group, the third harmonic has a path, and the short-circuit resistance is stronger than that of the Y, yn0 connection group transformer, and the D, yn11 connection group transformer has a certain filtering effect; therefore The quality of power supply is stable and the ability to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com