Method and device by which moulding compound to be processed is kept moist during the production of moulds or cores

A technology for manufacturing molds and cores, which is used in the field of mold materials and equipment for moisturizing to be processed when manufacturing molds or cores, can solve problems such as production stoppage, waste products, and high cleaning costs, and achieve the effect of avoiding drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

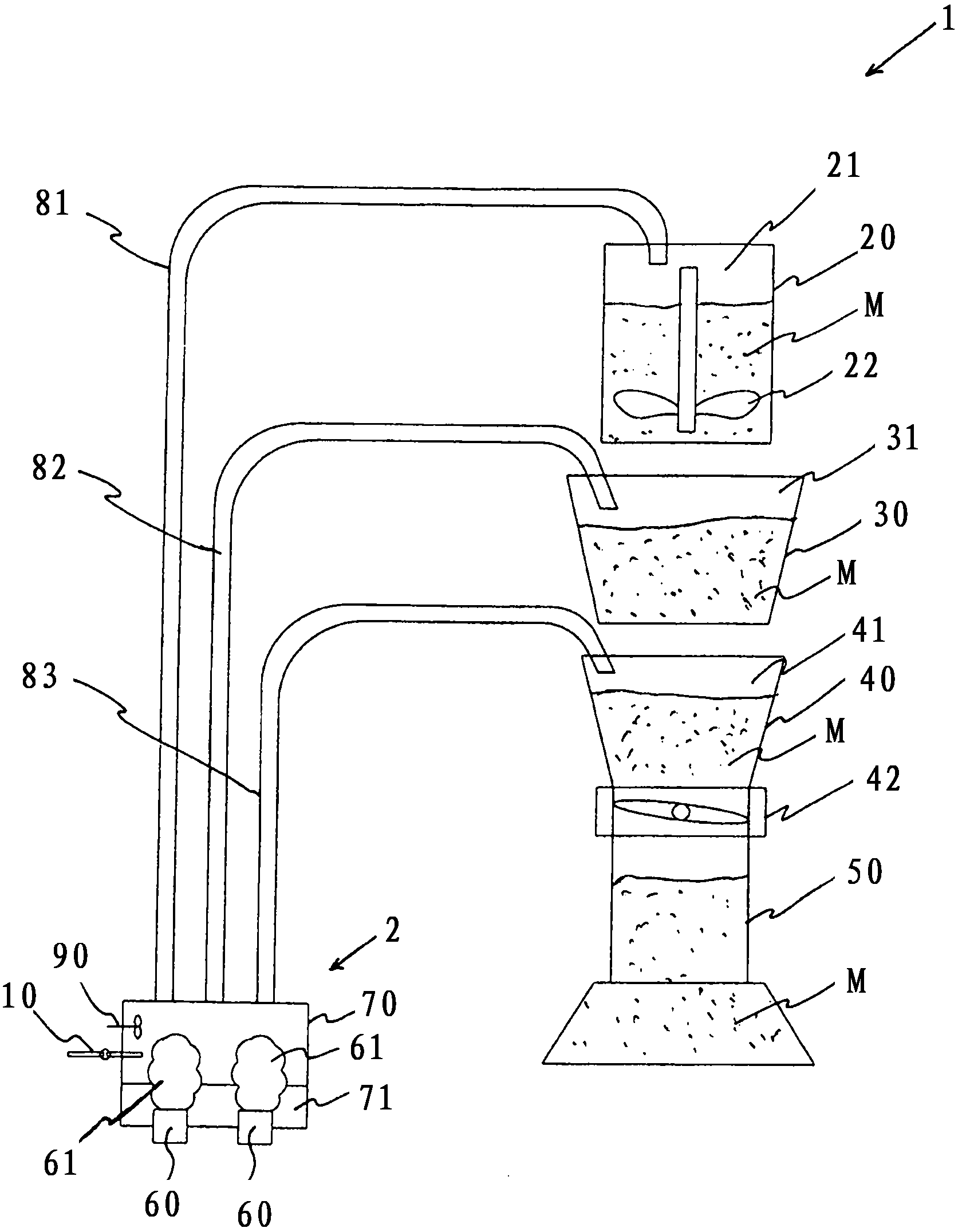

[0022] An apparatus for the manufacture of molds or cores, generally designated 1 , is used in this embodiment for the manufacture of cores for casting purposes, the apparatus having: a mixing device 20 with mixing means 22 for mixing the mold material Or molding sand and a binder to make mixture M; a conveying device 30 for conveying the mixture M to a molding sand storage unit 40 with a locking device 42 and a core or mold making device 50.

[0023] A humidifying device 2 is used to humidify the air in the device 1 , with two ultrasonic nebulizers 60 for water or for a liquid 71 , in particular containing water, and with a liquid container 70 . The liquid 71 can be atomized into fine aerosols by means of these ultrasonic nebulizers 60 . The aerosol is represented in the figure by two cloud bacteria 61 in the interior of the liquid container 70 .

[0024] However, a not-shown embodiment of the device can also provide that three ultrasonic nebulizers 60 are provided, one of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com