Method for operating an internal combustion engine having a multi-stage oil pump

A technology of internal combustion engine and oil pump, which is applied in the direction of engine lubrication, pressure lubrication of lubrication pump, lubrication pump, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

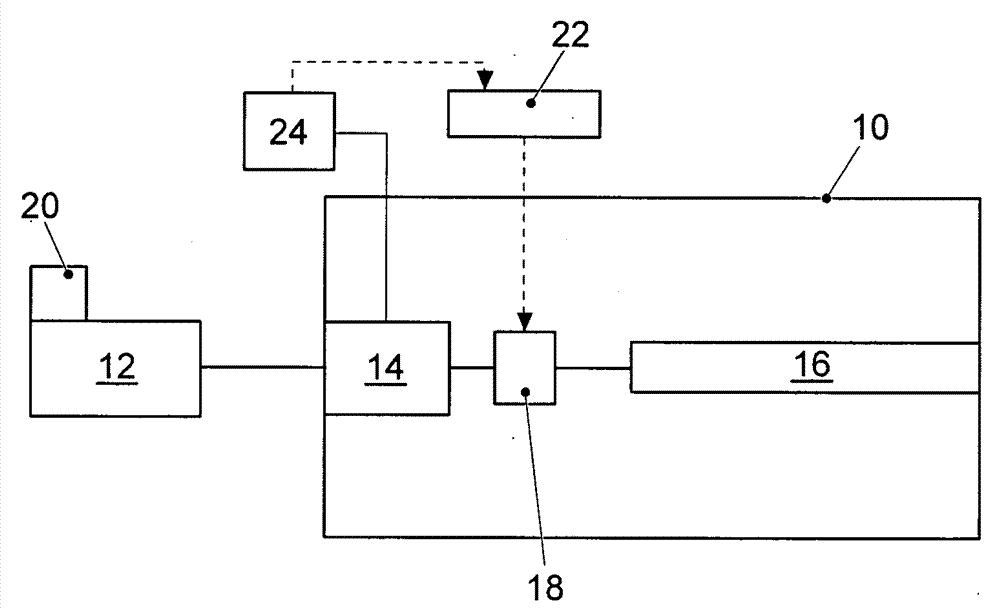

[0019] The present invention relates to an internal combustion engine, as in figure 1 As shown schematically in , the internal combustion engine has an engine block 10 , an oil pump 12 and an engine oil circulation device 14 designed in particular for pressure circulation lubrication. The adjustable hydraulic components, whose operating fluid is required for their actuation, are supplied by the engine oil of the engine oil circuit 14 , are connected into the engine oil circuit 14 for pressure circulation lubrication. The regulation of the fluid flow, that is to say the engine oil flowing through the hydraulic components, takes place via electrical control signals from the electronic control unit 22 . Such an adjustable hydraulic component is a hydraulic camshaft adjuster 18 for adjusting a camshaft 16 having hydraulic valves, which are designed, for example, as solenoid valves. In other words, the actuator for adjusting the camshaft is integrated into the engine oil circuit. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com