Disk brake, in particular for utility vehicles, and seal of a disk brake of said type

A technology for disc brakes, commercial vehicles, applied in the direction of brake components, brake types, axial brakes, etc., which can solve problems such as leakage, loss of pretension, and unprotected contact surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

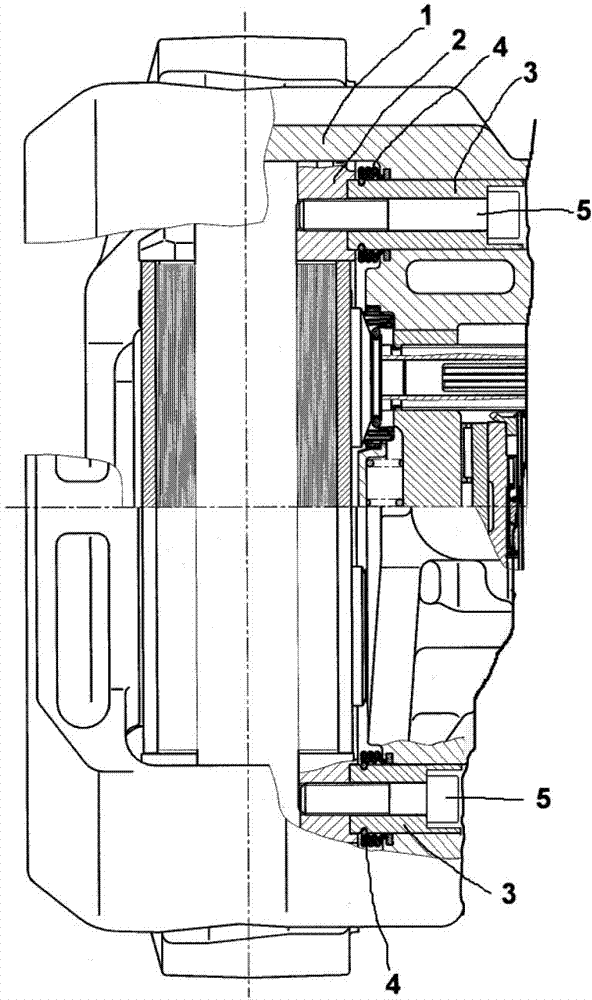

[0030] As already explained above, figure 1 A disc brake is shown with a brake caliper 1 , a carrier 2 , two guide pins 3 , 3 , two seals 4 , 4 and two cylindrical bolts 5 , 5 . Inside the brake caliper there is a pressing device, which is not further explained here, which is realized in the known manner in disc brakes of commercial vehicles by means of an eccentrically acting torsion bar pressing.

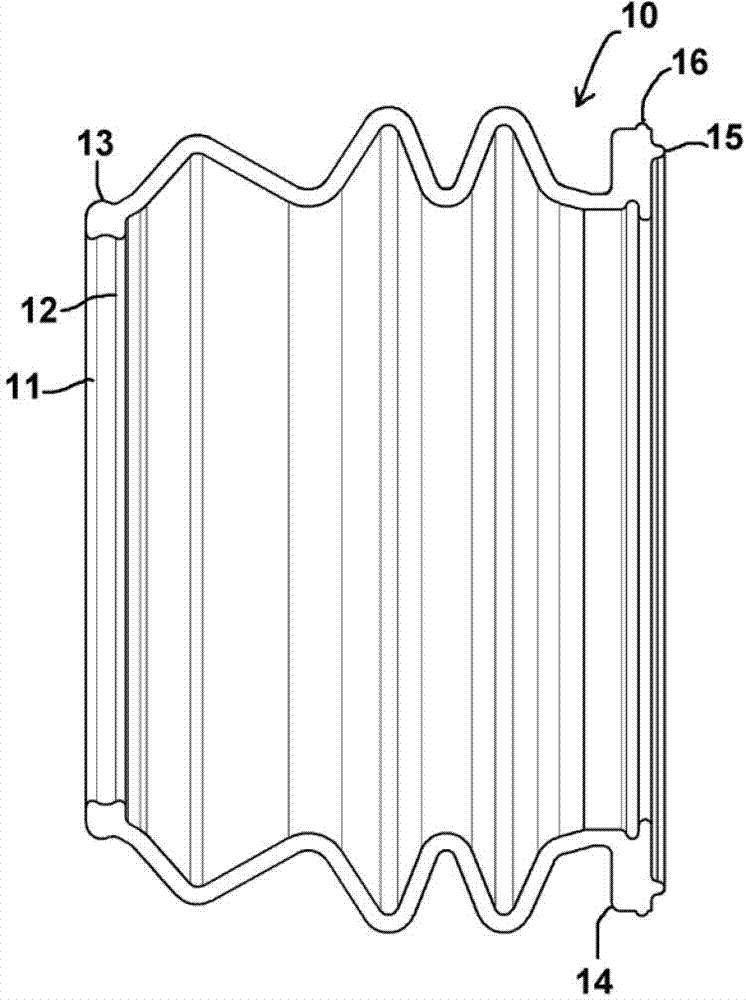

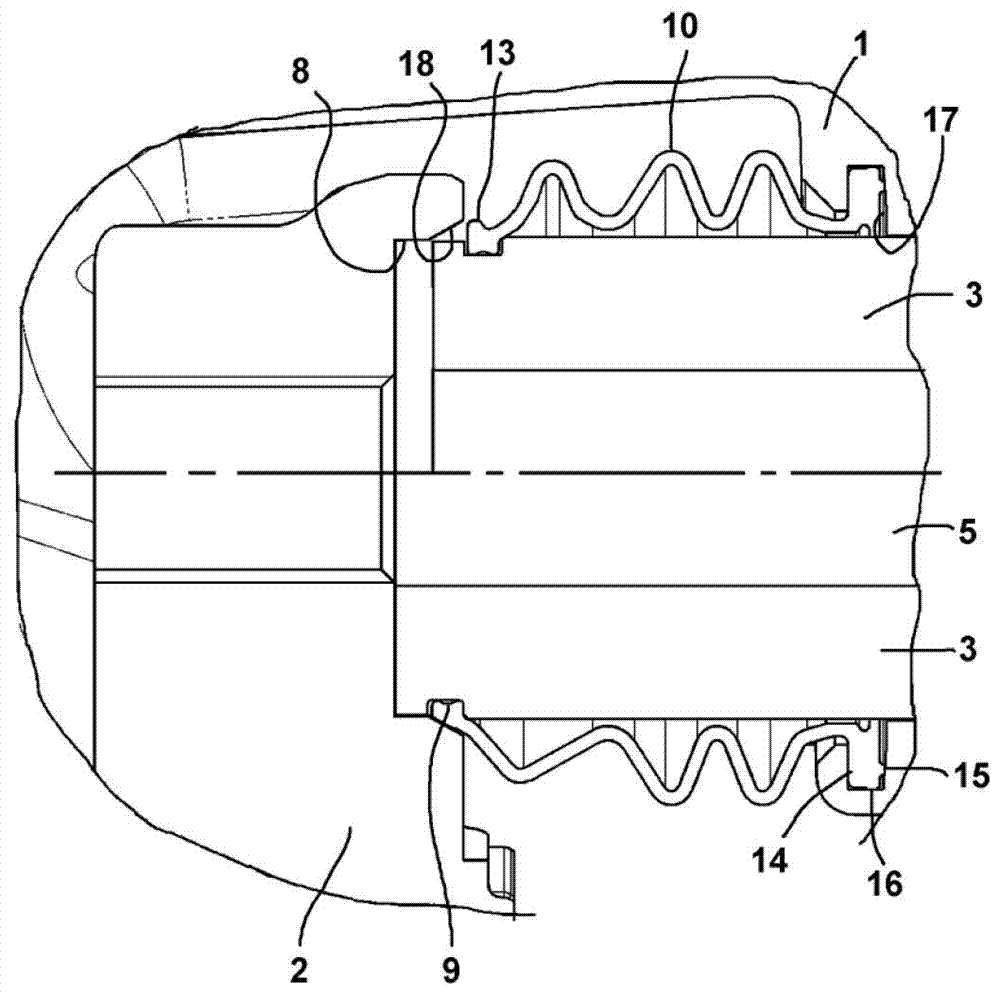

[0031] figure 2 The fixing of the seal 4 is shown in detail. According to this figure, the seal 4 is inserted into the annular groove 6 and surrounds the guide pin 3 in the form of a ring. The seal is elastically pretensioned in the radial direction in this annular groove 6 . Ring 7 is used for safeguarding. The guide pin 3 is inserted into the bead-shaped recess 8 of the carrier 2 with force and form fit and fixed with a cylindrical screw 5 . exist figure 2 The cylindrical bolt 5 for fixing the guide pin 3 in the groove 8 of the bracket 2 is not shown for the sake of clar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com