Wide-temperature heat control device

A warm, heat-conducting block technology, used in cooling/ventilation/heating transformation, modification with liquid cooling, electrical components, etc., can solve problems such as difficulty meeting site requirements and inability to add additional energy, achieving no potential safety hazards and resisting Influence, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

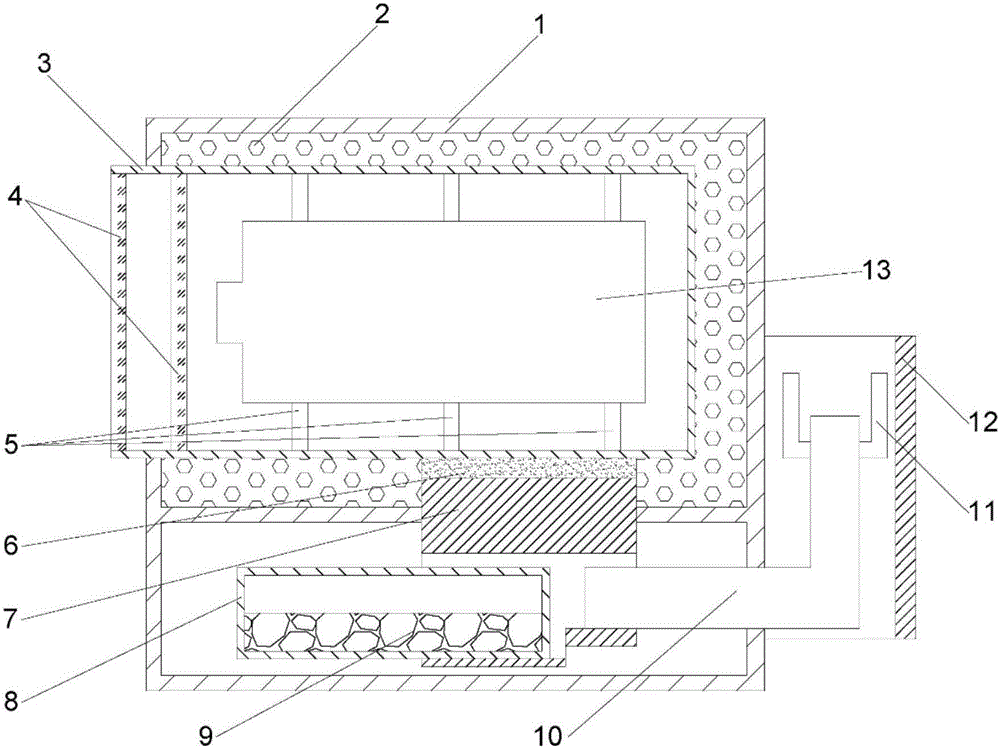

[0008] The wide temperature thermal control device proposed by the present invention has a structure such as figure 1 As shown, it includes an outer casing 1 , an inner casing 3 , a phase-change thermal pad 6 , a heat-conducting block 7 , a composite organic phase-change material box 8 , a thermal diode 10 and a heat sink 11 . The inner casing 3 , the phase change thermal pad 6 , the thermal block 7 , the composite organic phase change material box 8 and the thermal diode 10 are placed in the outer casing 1 . The inner casing 3 is placed in the upper part of the outer casing, and an insulating layer 2 is arranged between the outer casing 1 and the inner casing 3 . A glass window 4 is arranged on a side frame of the inner casing 3 , and the glass window 4 extends out of the outer casing 1 . The electronic device 13 to be protected is placed in the inner casing 3 , and the heat transfer between the electronic device 13 to be protected and the inner casing 3 is realized through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com