Loading and unloading device for a freeze-drying installation

A drying equipment and drying technology, applied in the direction of drying solid materials, dry goods handling, lighting and heating equipment, etc., to improve erection stability and save wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

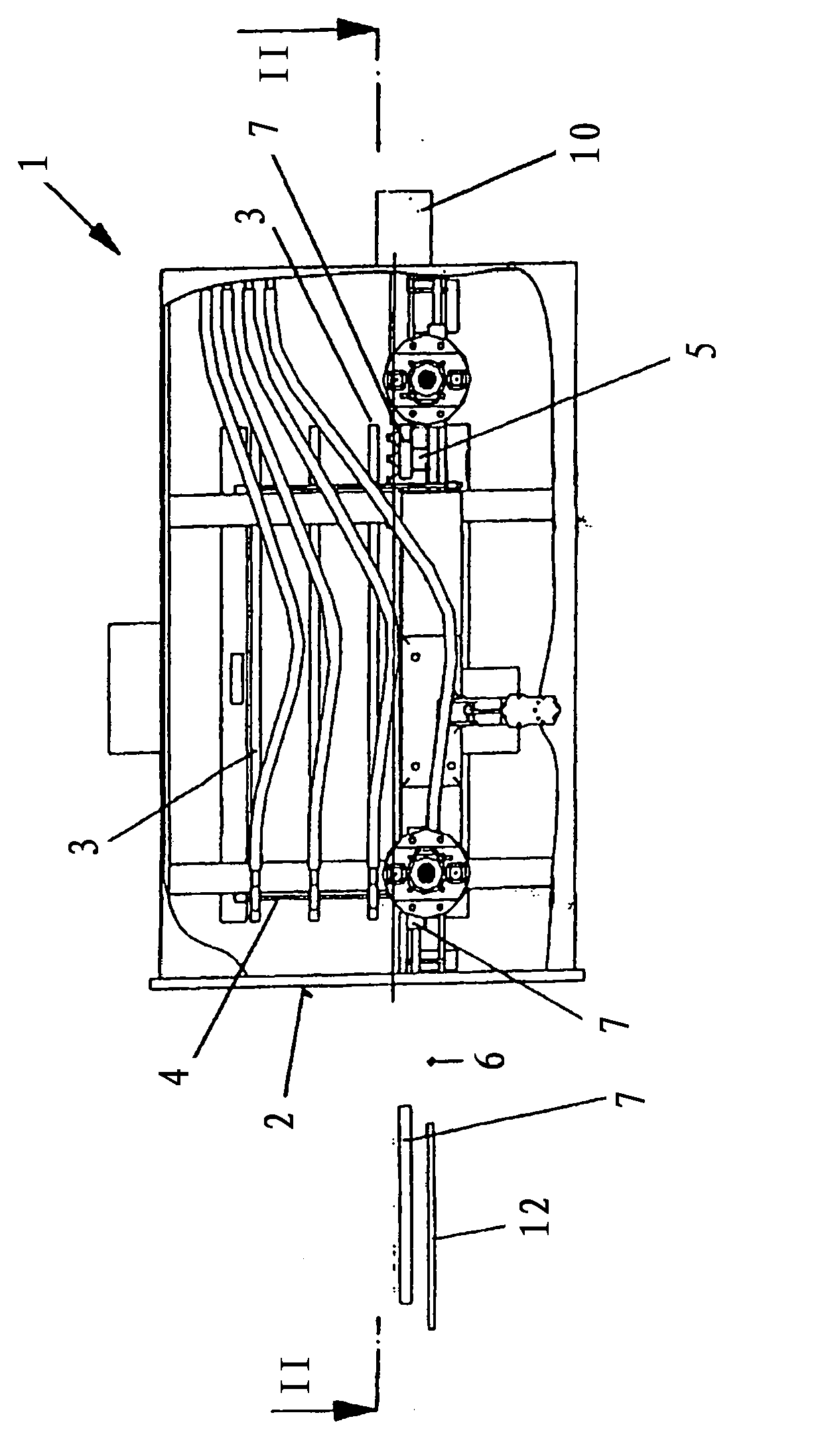

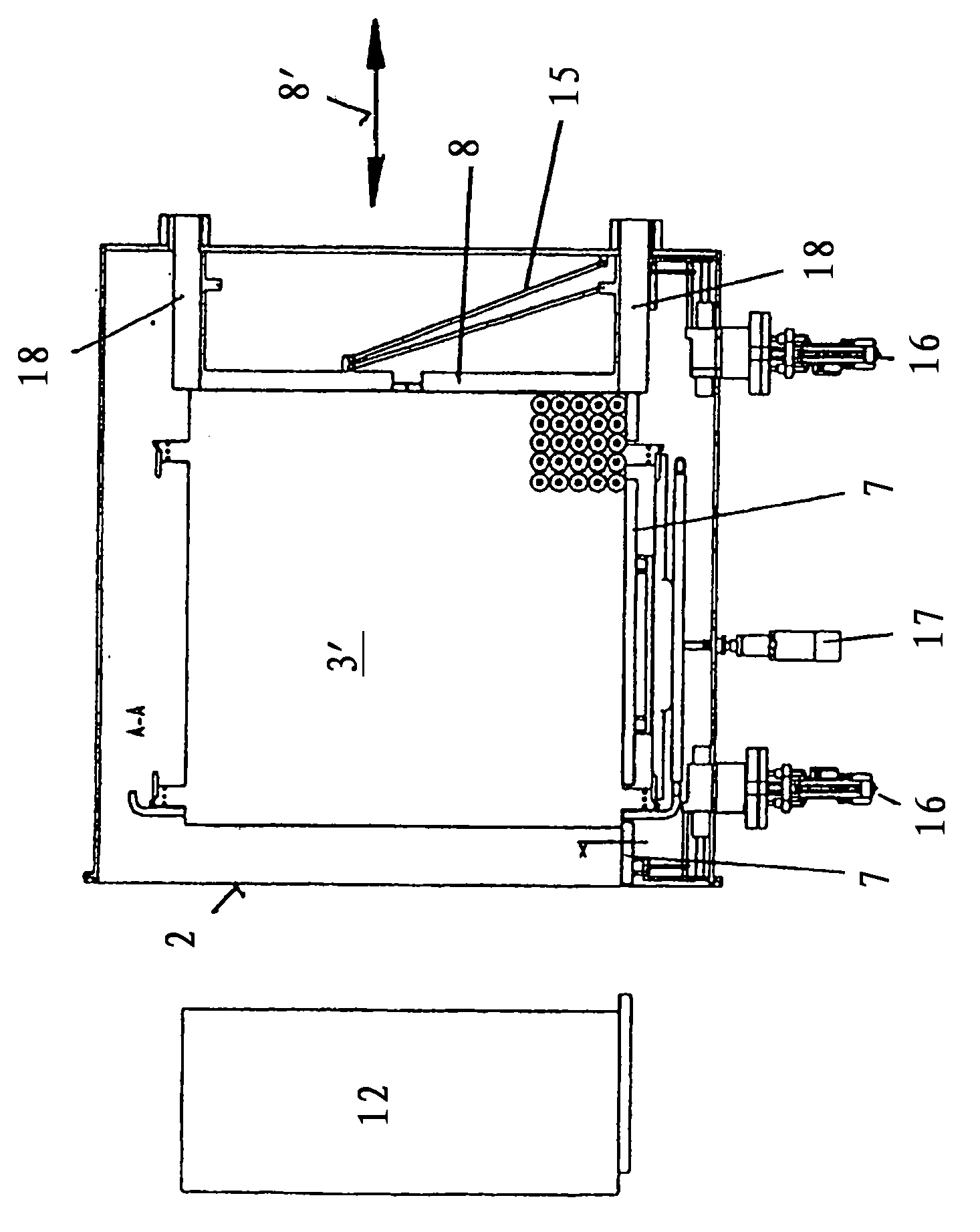

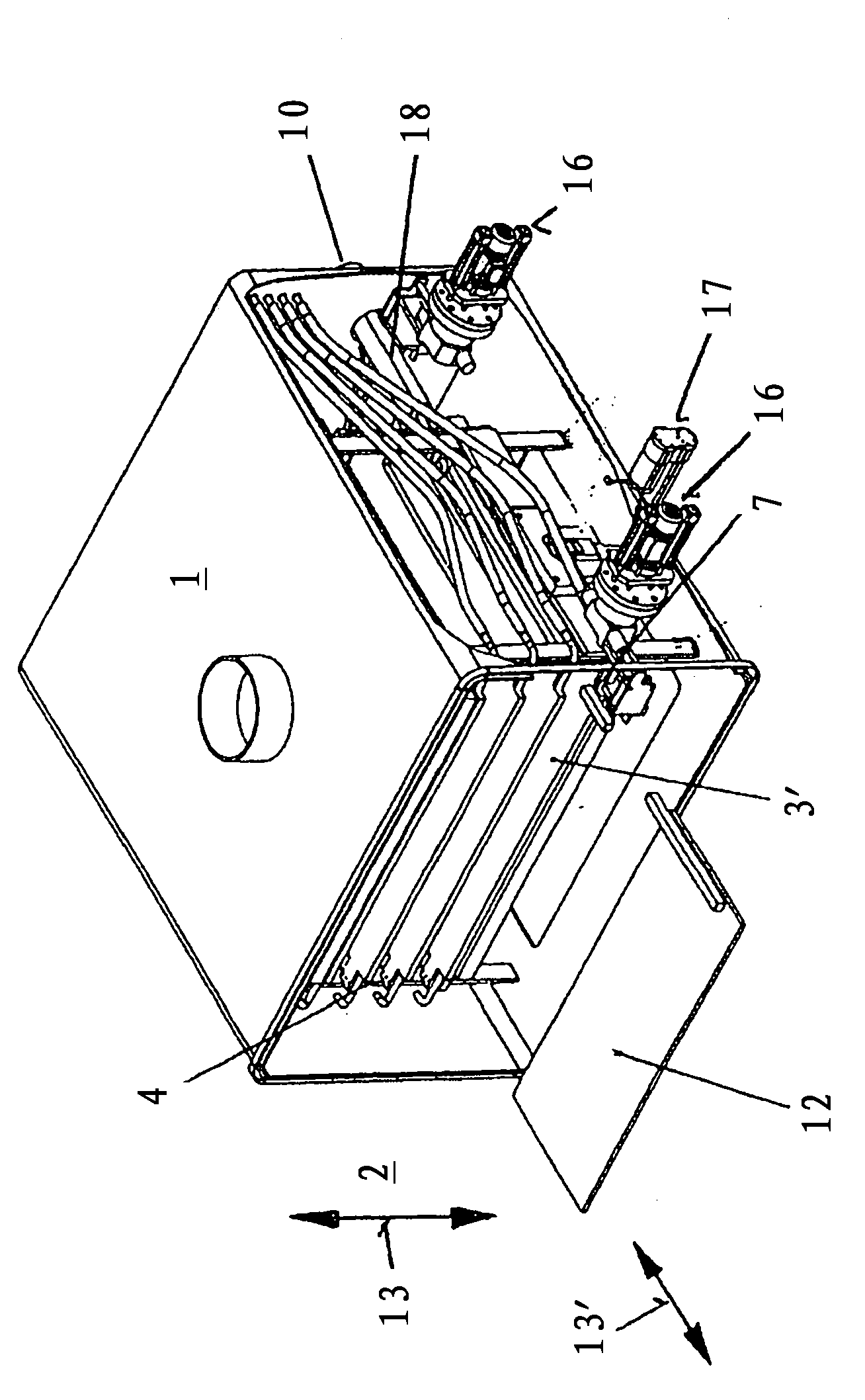

[0030] figure 1 The drying chamber 1 of the freeze-drying plant is shown in section, in whose front side 2 there is a not shown closeable opening for loading and unloading drying containers 5 . The drying chamber 1 is connected to the condenser chamber in a known manner, but will not be described in detail here.

[0031] Located in the drying chamber 1 is an assembly consisting of a rest surface, which is held vertically displaceably in a known manner in a support 4 . The support surface 3 is used for vertically placing drying containers 5 , each containing a drying substance, which can be removed from the drying chamber 1 after the drying process has been completed. The height position of the placement surface 3 ′, which corresponds to the unloading position of this placement surface, is indicated with reference numeral 6 . It is important that the vertical adjustability of all placement surfaces 3 of the support 4 is arranged in such a way that each placement surface 3 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com