Electrode support arm system

An electrode and supporting device technology, applied in the field of electric arc furnaces and boilers, can solve problems such as damage to insulating materials and arcing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

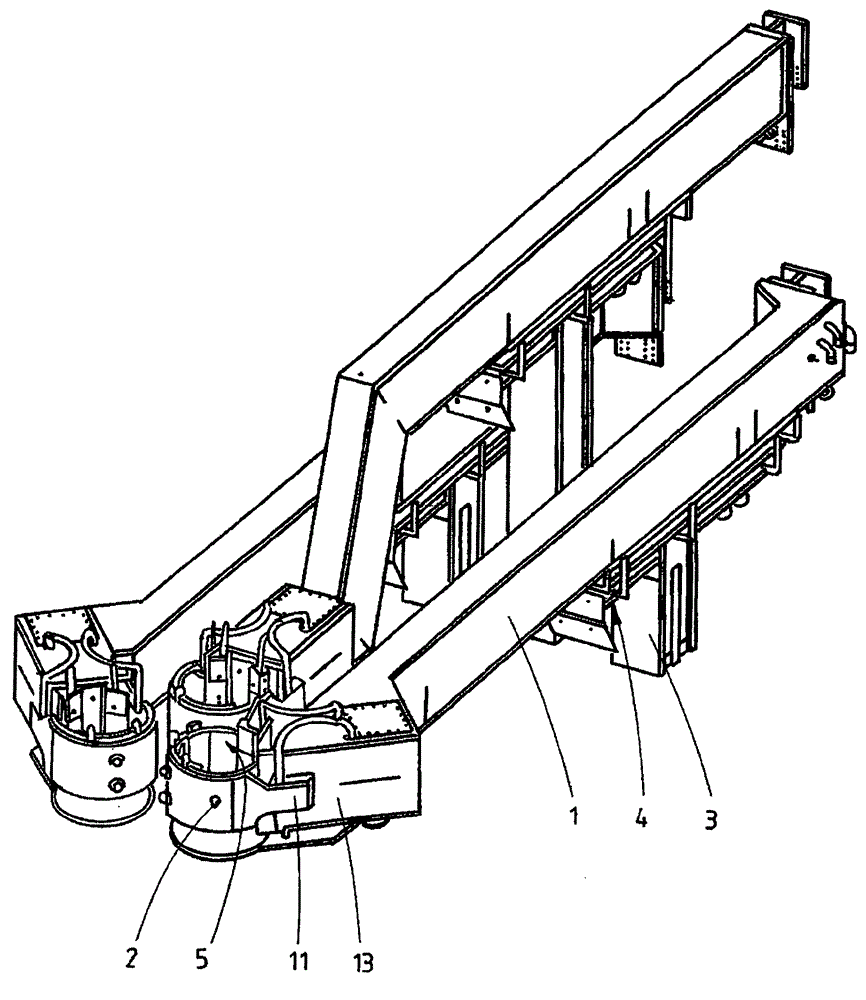

[0024] In the present case, three electrode supports 1 are provided, which essentially consist of welded hollow profiles.

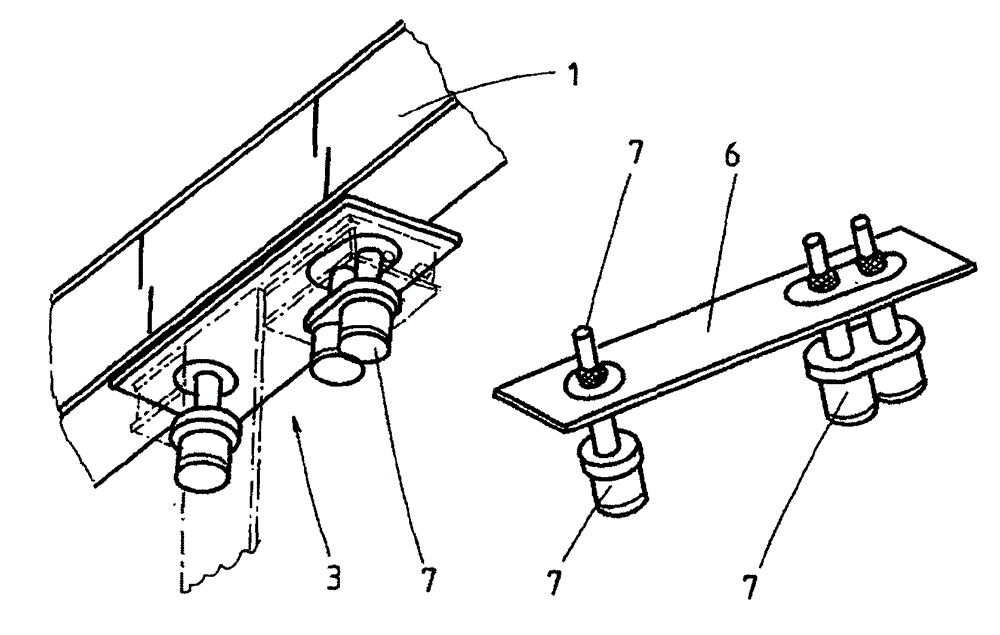

[0025] A guide post 3 is assigned to each electrode arm, the respective electrode arm being detachably connected to its head region. An example for this connection is at image 3 , wherein, here, the separating plate 6 arranged between the guide post head and the electrode support arm is shown. The real detachable connection is produced by the screw 7 made of antimagnetic material.

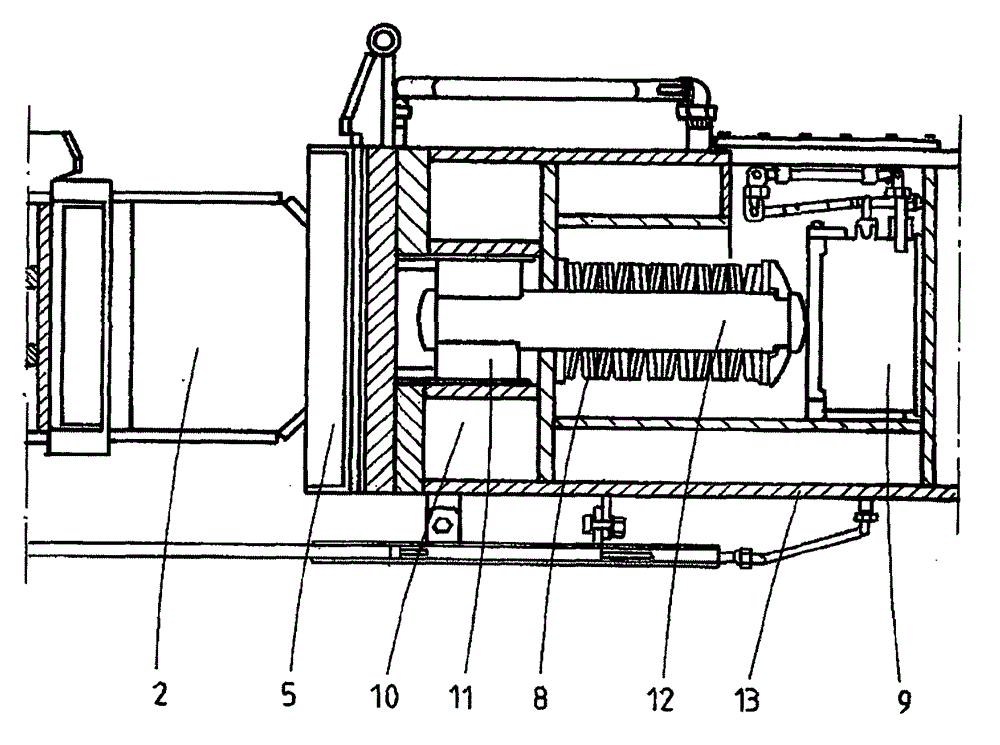

[0026] exist figure 2 The front region of the electrode support arm 1 with the electrode support 2 (ie the electrode support arm head 13 ) is reproduced in detail in .

[0027] The holder 2 surrounds the electrodes (not shown here) over a large part of its circumference and presses them against the contact clips 5 .

[0028] as from figure 2 It can be seen in the cross section that the support 2 surrounding the electrode is in operative connection via the arm 11 with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com