Method for operating a gas discharge lamp and gas discharge lamp system

A technology for gas discharge lamps and driving gas, which is applied to electric light sources, electrical components, lighting devices, etc., can solve problems such as expensive costs, and achieve the effects of low cost, reduced deviation, and low electric strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

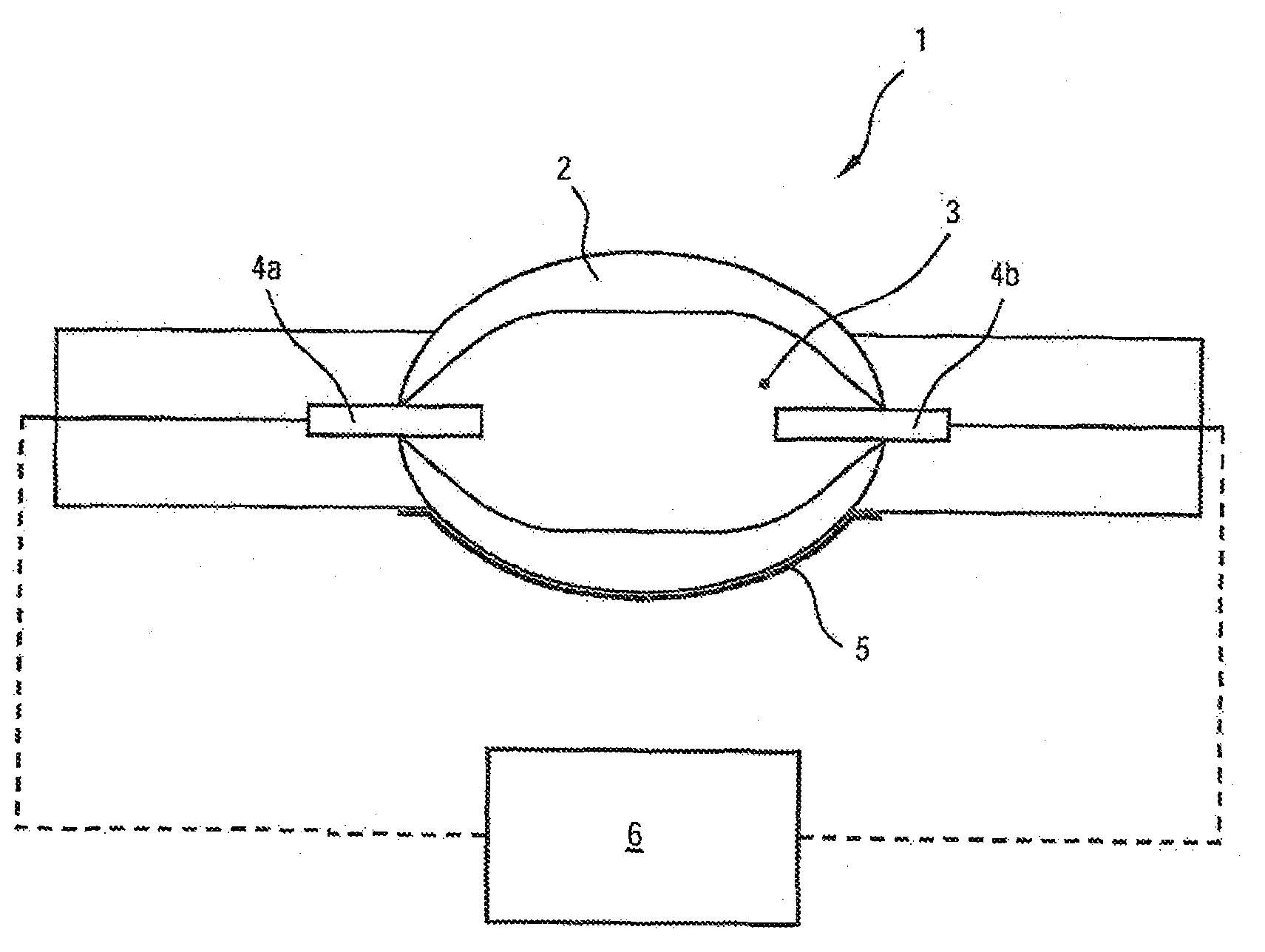

[0028] figure 1 A gas discharge lamp 1 is shown with a discharge vessel 2 in a cavity 3 of which two electrodes 4a, 4b are located and which is filled with a mercury-free vapor filling. Here, a capacitive ignition aid element (“capacitive ignition aid”) 5 is present on the outside of the discharge vessel 2 . The ignition aid 5 forms a capacitance towards each of the electrodes 4a, 4b, which is charged or recharged with each half-wave of the high-frequency alternating voltage. An alternating electric field is thus formed in the cavity 3 , which causes a dielectric barrier discharge of the gas atoms or gas molecules present in the cavity 3 . The discharge generates charge carriers via the electrodes 4a, 4b for completely igniting the gas discharge lamp 1 .

[0029] The ignition aid element 5 can comprise at least one ignition aid layer, an ignition aid wire, a cladding clip, a return wire or the like. The ignition aid 5 can basically form a capacitance with both electrodes 4a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com