Residual accumulator plate coating lead-plaster blowoff and recovery device

A technology for recycling devices and storage batteries, which is applied to the device and coating of the surface coating liquid, which can solve the problems of affecting the appearance of the polar plate, the weight and quality of the polar plate, the difficulty of accurately removing the remaining paste, and the inconvenience of processing, etc., to achieve guaranteed Appearance effect and quality, simplification of subsequent processing procedures, and the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

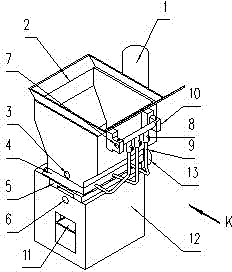

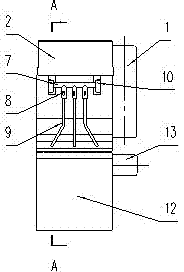

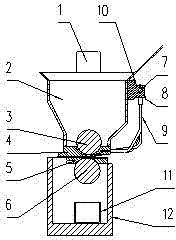

[0022] See Figure 1, Figure 2, image 3 , the present invention is made up of excess paste blowing mechanism and excess paste recovery mechanism, and described excess paste blowing mechanism comprises support 10, air inlet pipe 7, air valve 8, ventilation pipe 9 and upper paste plate 4, and described support 10 is fixed on the side wall of the plaster hopper 2 of the coating machine, the air inlet pipe 7 is installed on the support 10, the air inlet pipe 7 is connected with the high-pressure air source, and a group of air outlets are arranged on the side wall of the air inlet pipe 7, and each An air valve 8 is installed at each air outlet, and the air valve 8 is connected with a vent pipe 9 , and the vent pipe 9 is connected with the upper plaster plate 4 .

[0023] see image 3 , Figure 4 , the upper paste plate 4 of the present invention is located at the bottom of the paste hopper 2 of the coating machine, and the upper paste plate 4 cooperates with the upper paste rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com