Large aluminum alloy wheel hub forging hydraulic press

An aluminum alloy wheel hub and forging molding technology, which is applied in the direction of swaging presses, forging presses, forging presses, etc., can solve the problems of human poisoning, inability to protect the health of workers, and health hazards of operators, so as to prevent injuries, Avoid heat loss, improve safety and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

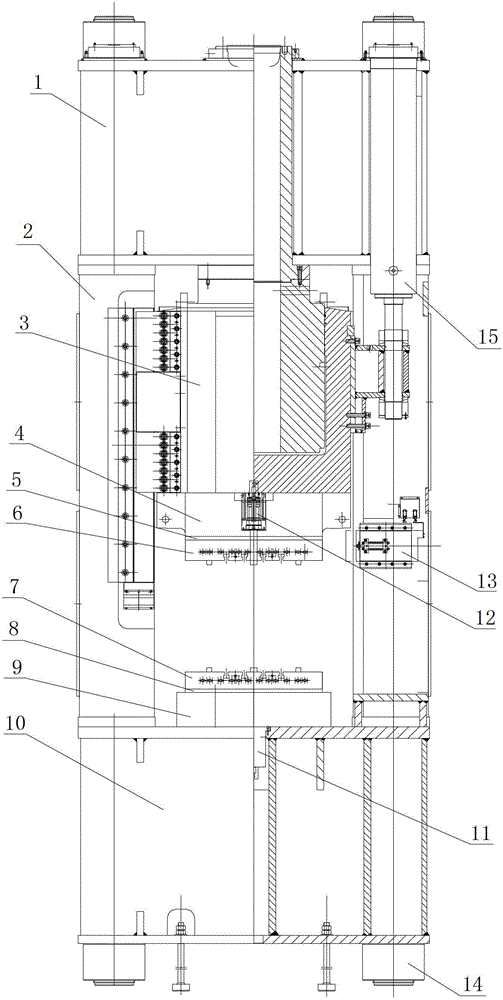

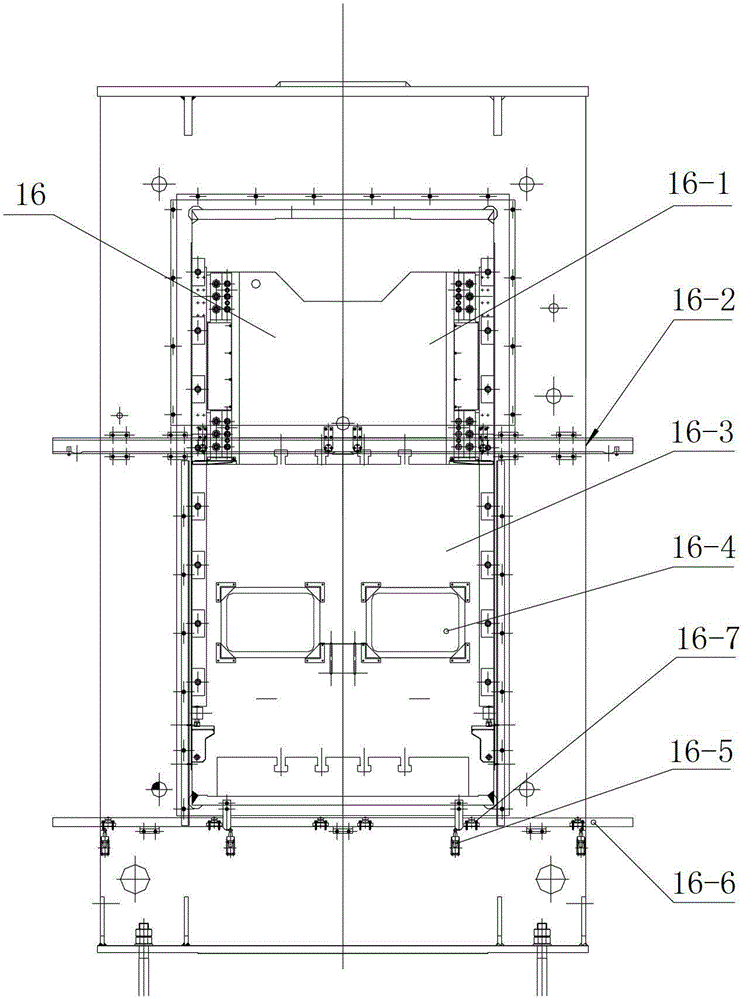

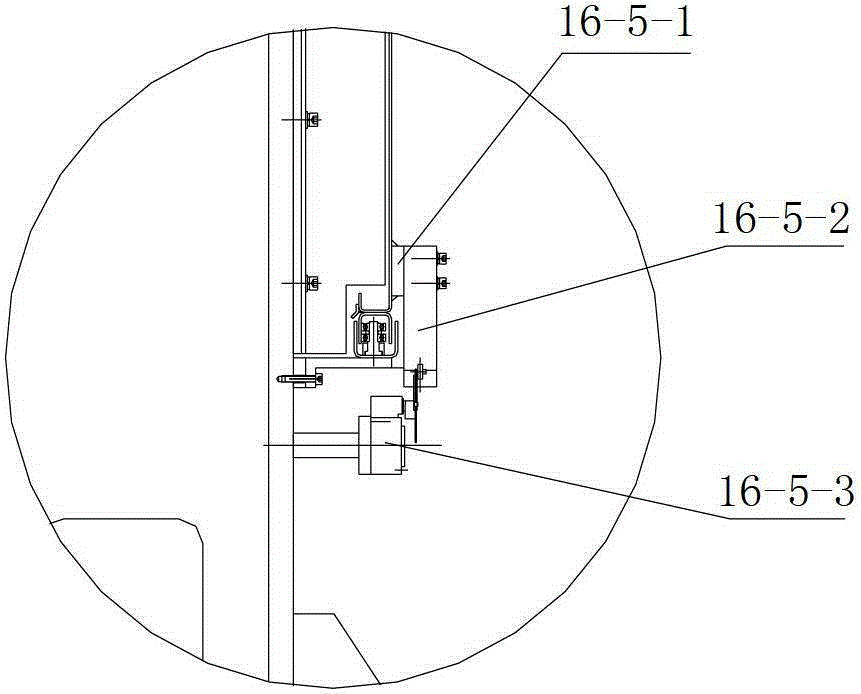

[0025] see Figure 1-Figure 6 , a large aluminum alloy wheel hub forging hydraulic press, including a frame structure fuselage composed of an upper beam 1, a pillar 2, and a lower beam 10 fastened by a tie rod lock nut 14. The upper beam is fixed with a cylinder slider 3 and a return cylinder 15 by fasteners, and the cylinder slider is located in the middle area of the fuselage, and the connecting body and plunger on the cylinder slider are fixed by a lock nut On the upper beam, the pressurization work of the slider can be realized when there is liquid pressure in the slider with cylinder, and the return cylinder 15 for the return of the slider with cylinder is respectively arranged on the left and right sides of the upper beam. The upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com