Circle shear device for both trimming and slitting of aluminum strips

A technology for disc shears and aluminum strips, which is applied to cutters, shearing devices, and accessories of shearing machines, etc., can solve the problems of cumbersome control methods, high costs, and high energy consumption, and can ensure Accuracy, harm avoidance, time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The dual-purpose disc shear device for edge trimming and splitting of the aluminum strip provided by the present invention will be described in detail below in conjunction with the accompanying drawings, an example of which is shown in the accompanying drawings, wherein the same reference numerals always represent the same components.

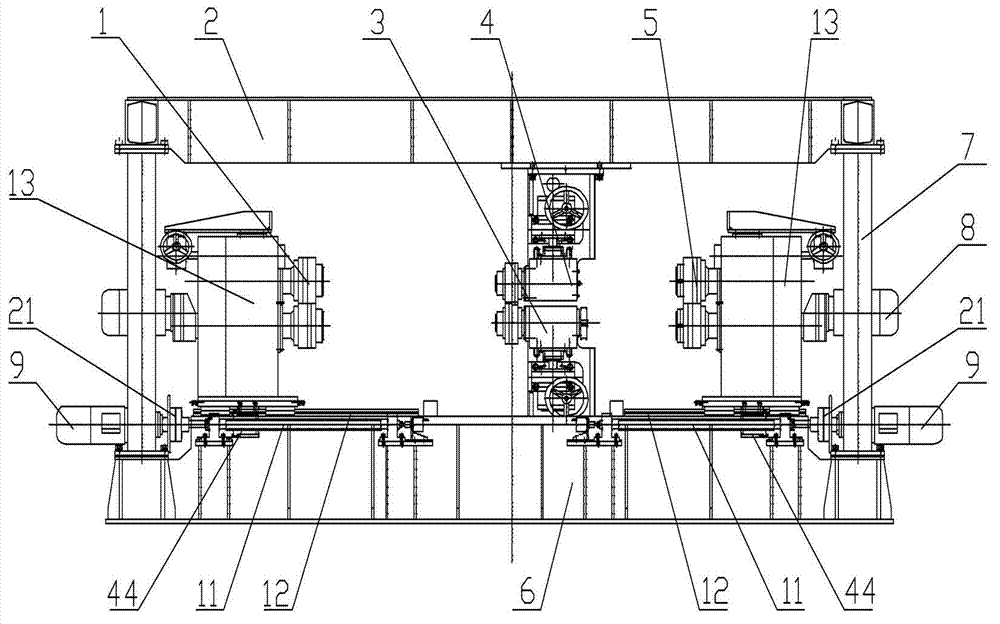

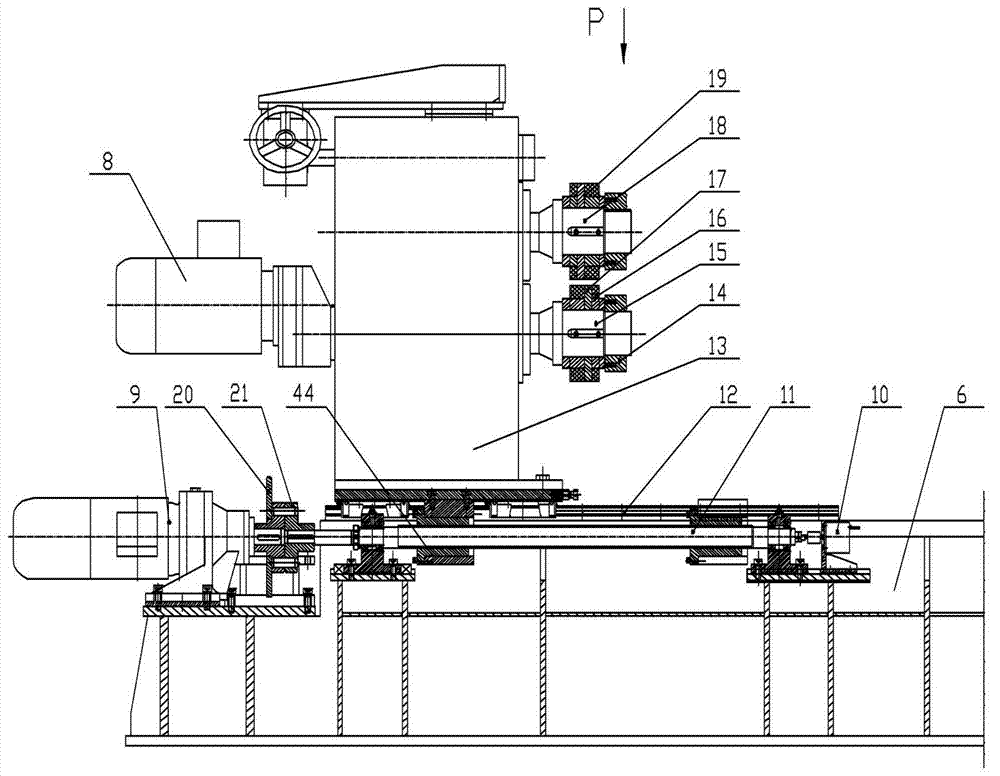

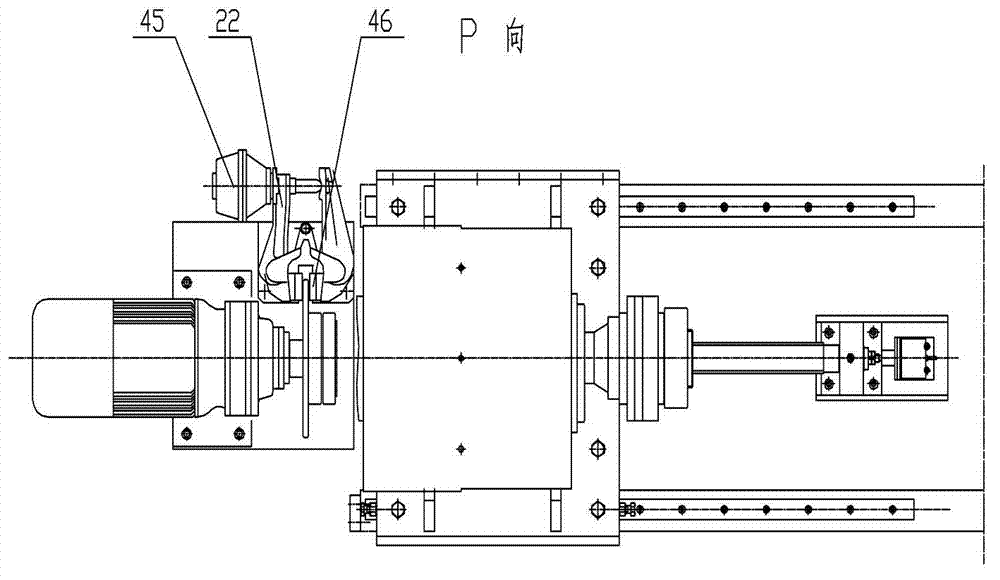

[0028] figure 1 It is the structural representation of the disc shear device provided by the present invention, as can be seen from the figure: the disc shear device comprises an upper shearing device suspension crossbeam 2 positioned at the top of the disc shear device, a base 6 positioned at the bottom of the disc shear device and The box body 13 located on both sides of the disc shear device, the operating side knife rest and locking device 1 and the driving side knife rest and locking device 5 are installed on the respective box bodies 13, and the two box bodies 13 are placed on the linear guide rail 12 Above, the bottom of the two b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com