Umbrella-type inner support clamp for annular welding of elongated cylindrical workpieces

An inner support fixture, a cylindrical technology, is applied in the field of inner support fixtures for circular welding of small-diameter cylindrical workpieces, which can solve the problems of low welding efficiency and poor welding precision, and achieve high welding precision, convenient operation, and reduced The effect of welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

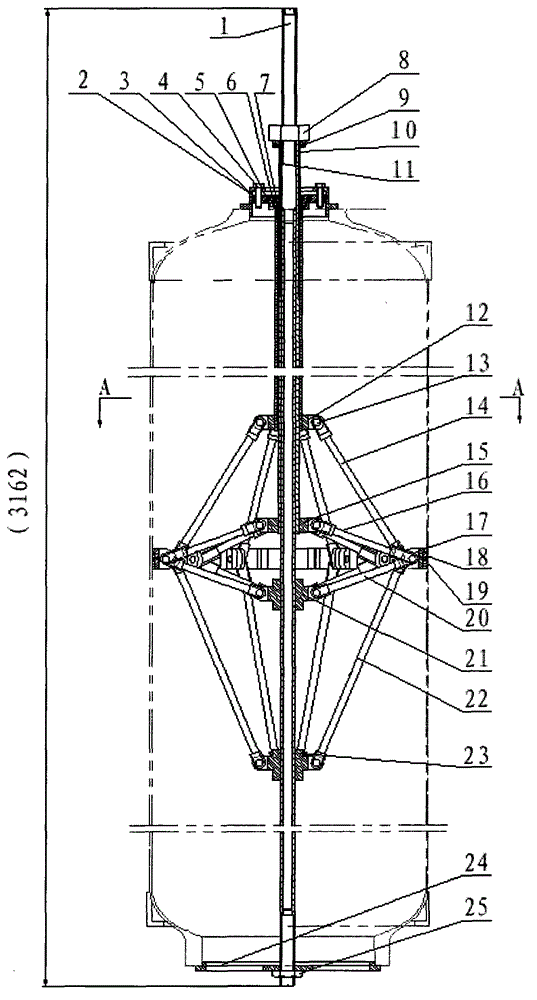

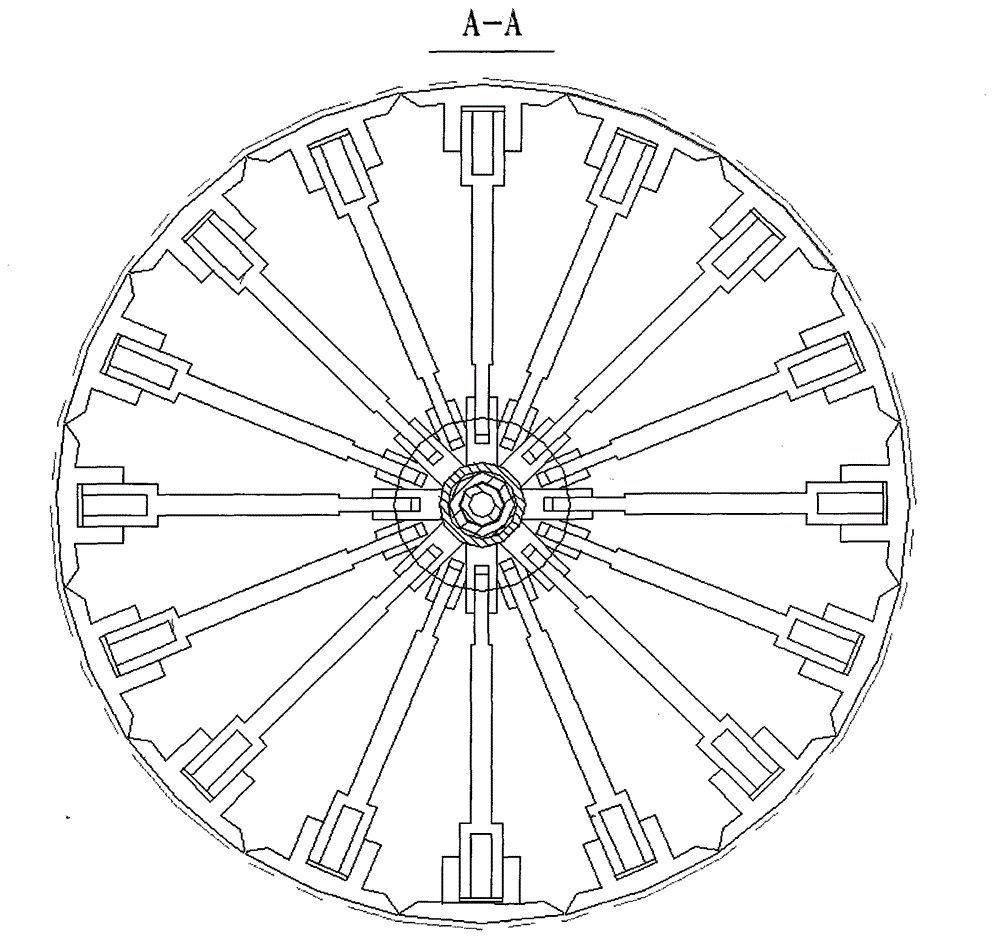

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0026] like figure 1 As shown, the umbrella-shaped inner support fixture for welding is composed of four parts: the main shaft 1, the front-end locking device, the weld seam tightening device, and the rear-end pressing device. The main shaft 1 connects the three major devices into one body. become one. The overall length of the umbrella-shaped inner support fixture is 3162 mm. figure 1 Marked with a double dotted line in is the cylindrical workpiece to be welded.

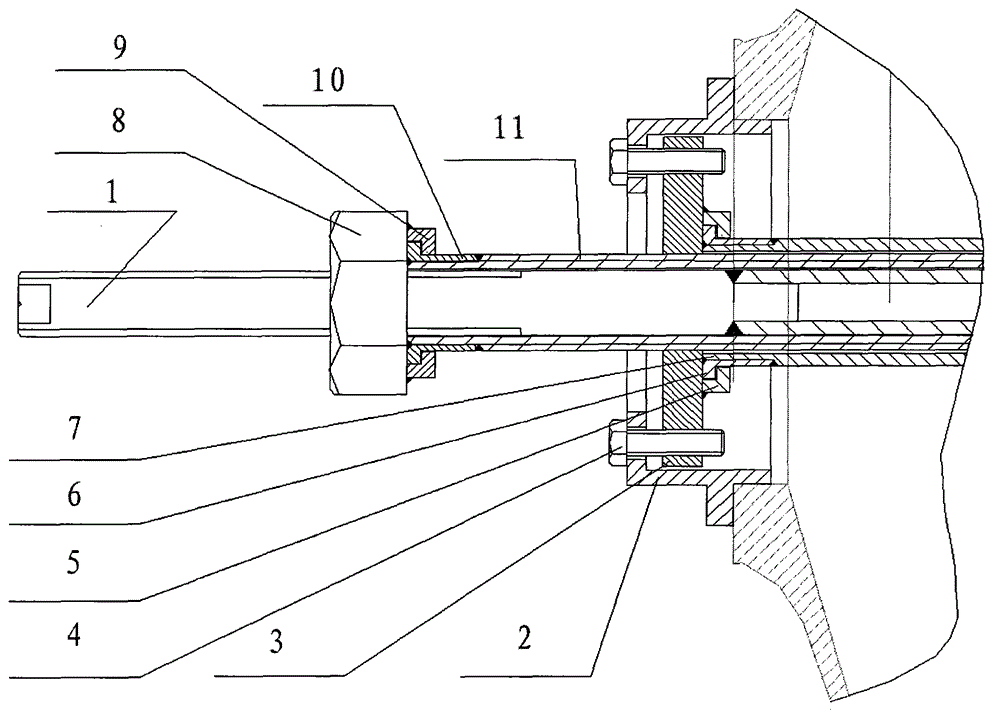

[0027] like image 3 As shown, the front-end locking device consists of front-end cover 2, front plug 3, bolt 4, tension ring I5, load-bearing ring I6, sleeve I7, load-bearing nut 8, tension ring II9, load-bearing ring II10 and sleeve Composition of cylinder II11. Among them, the tension ring I5 is set on the load-bearing ring I6, and is welded together with the front plug 3, the load-bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com