High-speed full-automatic packing machine

A fully automatic packaging machine, high-speed technology, applied in packaging, transportation packaging, multiple packages, etc., can solve the problems of low production efficiency, low technical level, high packaging cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

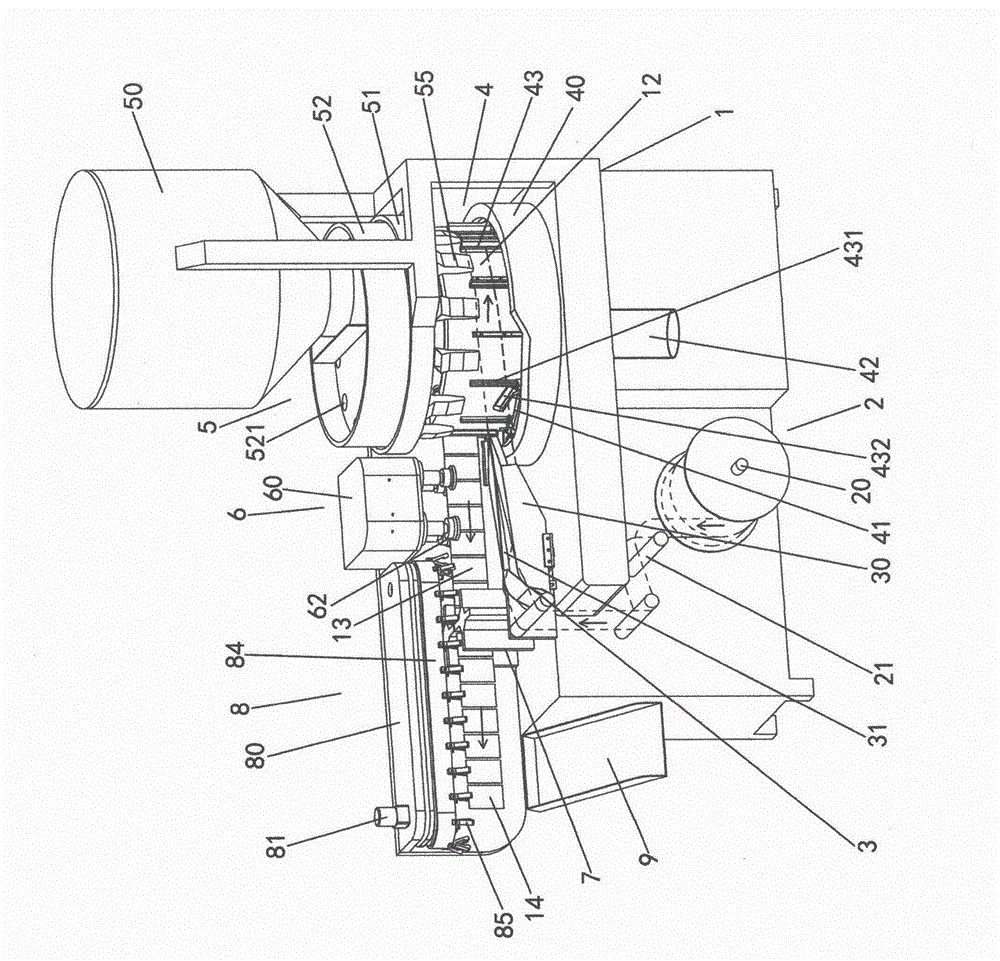

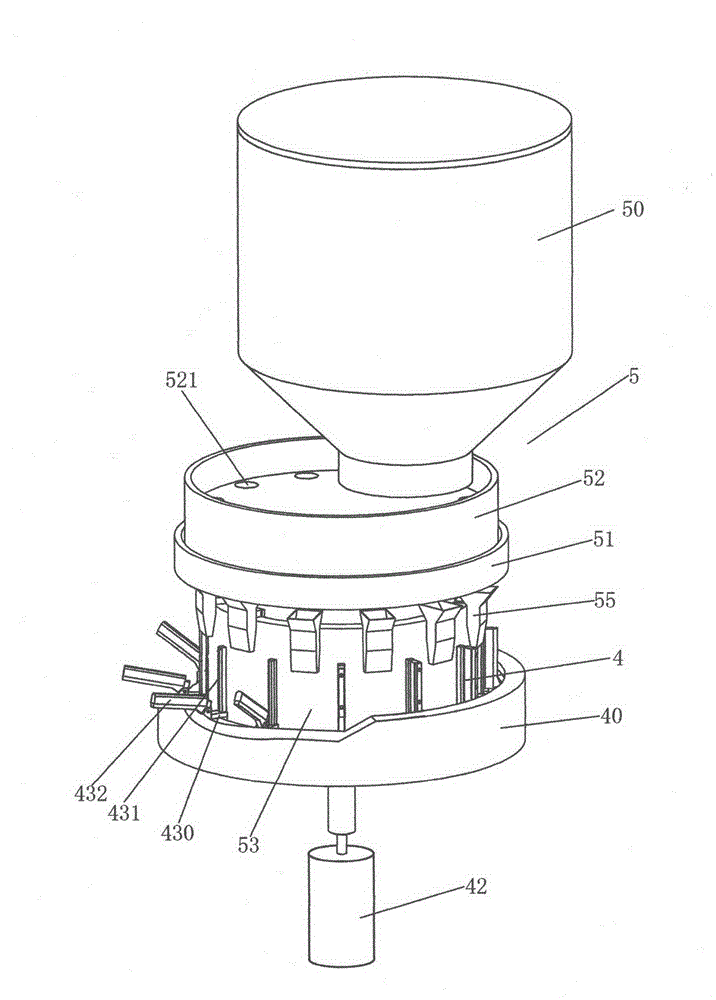

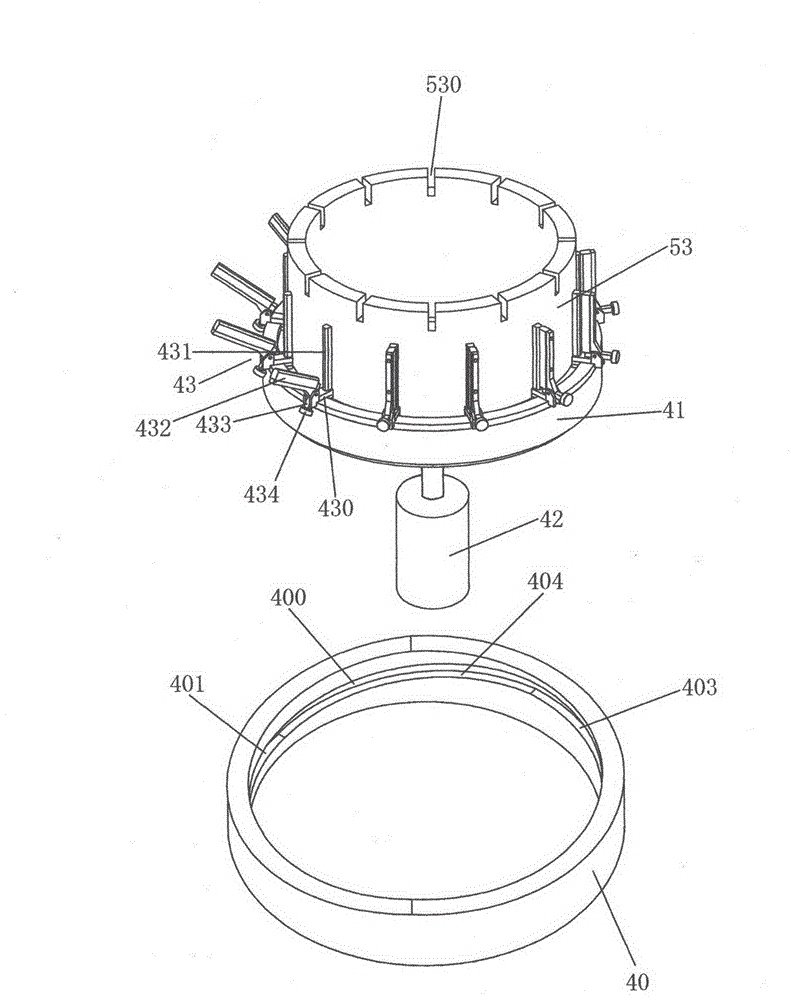

[0055] Such as Figure 1 to Figure 7 As shown, the high-speed automatic packaging machine in this preferred embodiment includes a frame 1 and a film releasing device 2, a packaging bag forming device 3, a longitudinal sealing device 4, a filling device 5, and a sealing device respectively arranged on the frame 1 6. Shearing device 7, bag feeding device 8 and finished product output device 9;

[0056] The above-mentioned film releasing device 2, packaging bag forming device 3, longitudinal sealing device 4, sealing device 6, bag feeding device 8 and finished product output device 9 are arranged in sequence along the conveying direction of the packaging material (that is, packaging film or packaging bag). The device 5 is located above the longitudinal sealing device 4, and the above-mentioned finished product output device 9 is located below the bag feeding device 8;

[0057] The above-mentioned unwinding device 2 includes an unwinding shaft 20 and a plurality of tension roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com