Spliced packing box for liquid crystal glass panels

A technology of liquid crystal glass and packaging boxes, which is applied in the field of packaging, can solve the problems of large space occupation, high transportation costs, and high development costs, and achieve the effects of simple structure, avoiding damage, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

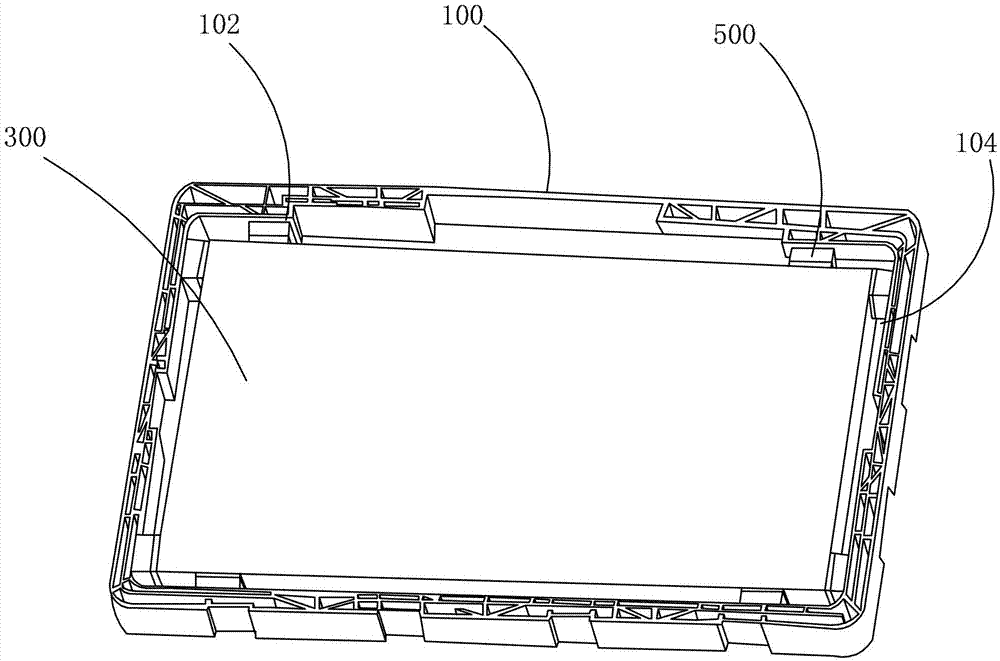

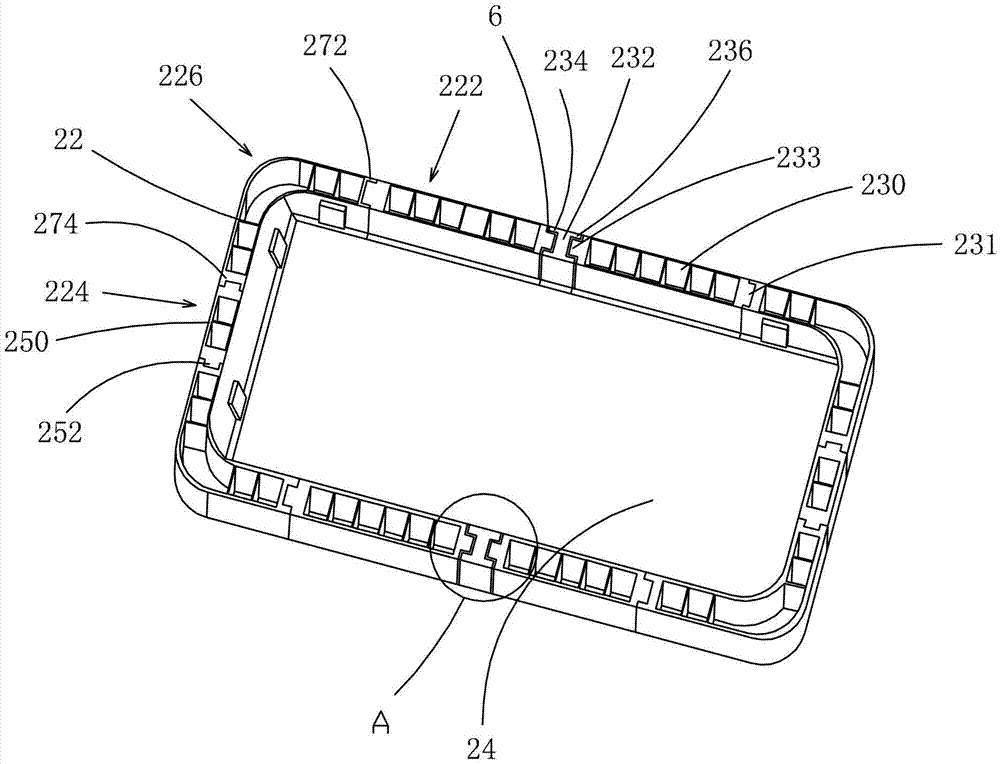

[0028] see Figure 2 to Figure 4 , the present invention provides a splicing type liquid crystal glass panel packaging box, comprising: a box body 2 and several brackets 4 installed on the box body 2, the box body 2 includes a frame body 22 and a hollow body arranged in the frame body 22 plate 24.

[0029] The frame body 22 includes two opposite first frames 222 , two opposite second frames 224 , and four L-shaped connecting frames 226 connecting the first frames 222 and the second frames 224 .

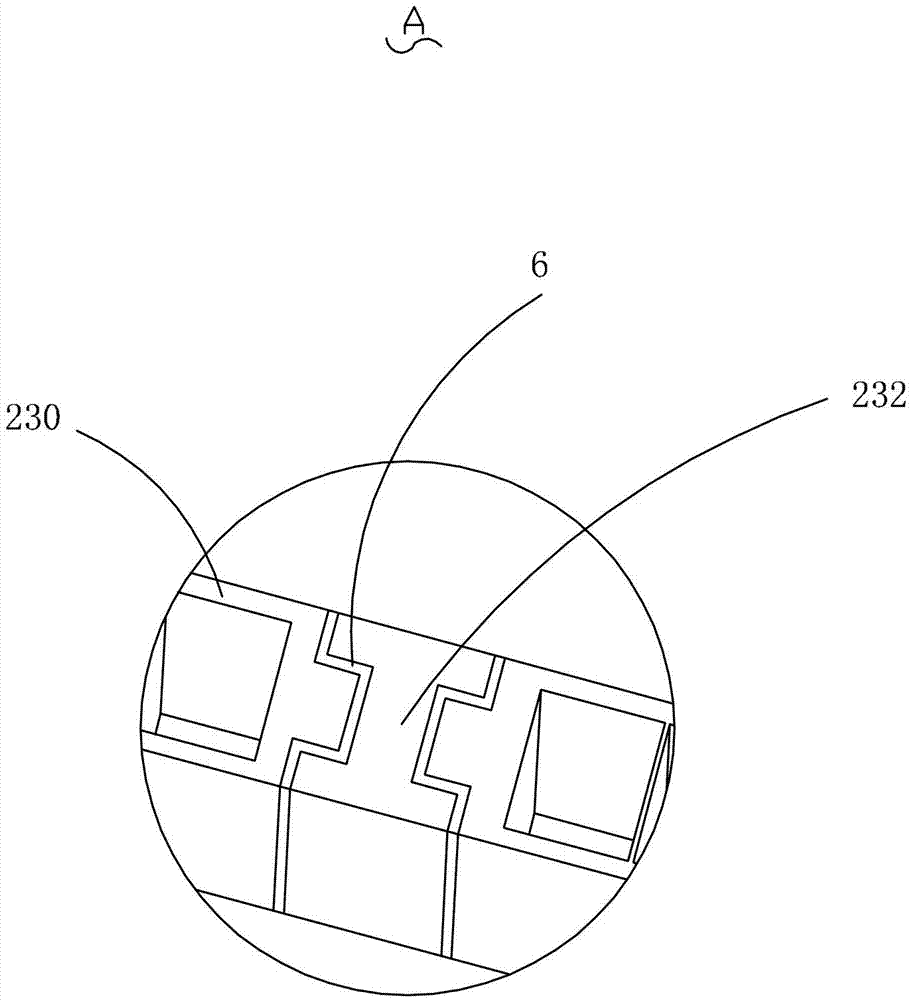

[0030] The first and second frames 222, 224 are in the shape of a line respectively, and each first frame 222 includes several first frame units 230 and several first connectors 232 connected between the two first frame units 230, Each second frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com