Heat storage type lime rotary kiln

A lime rotary kiln and regenerative technology, applied in lime production and other directions, can solve problems such as energy consumption restricting the development of rotary lime kilns, and achieve the effects of reducing lime production costs, reducing energy consumption and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

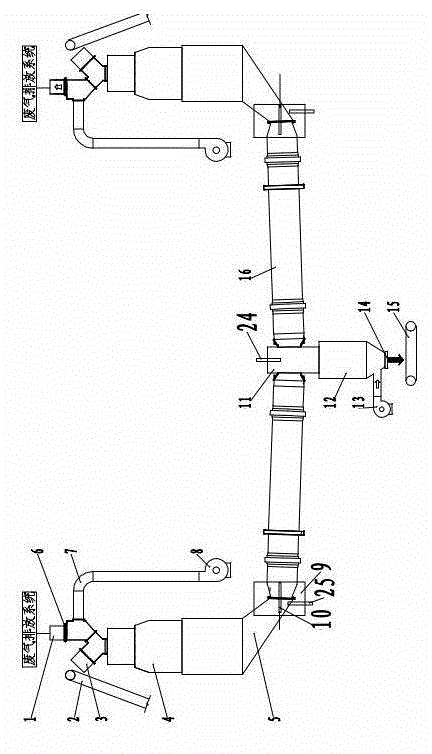

[0021] Regenerative lime rotary kiln of the present invention such as figure 1 As shown, it includes two kiln bodies 16, two preheating chambers 4, kiln tail cover 11, cooling chamber 12, burner 10, blower 8, kiln head 9, cooling fan 13, feeding system 2 and exhaust gas discharge system, A burner 10 is arranged in the kiln head. The two kiln bodies are symmetrically arranged left and right, one end of the kiln body is connected to the cooling chamber through the kiln tail cover 11, and the other end is respectively connected to the outlet of the preheating chamber 4 through the feeding chamber 5. The inlet of the preheating chamber is respectively connected with the feed port 3 and the three-way valve 17 through a three-way pipe 18 . One of the other two paths of the three-way valve is connected to the blower through the air pipeline 7, and the other is connected to the exhaust gas discharge system; the cooling fan is connected to the lower part of the cooling chamber, and th...

Embodiment 2

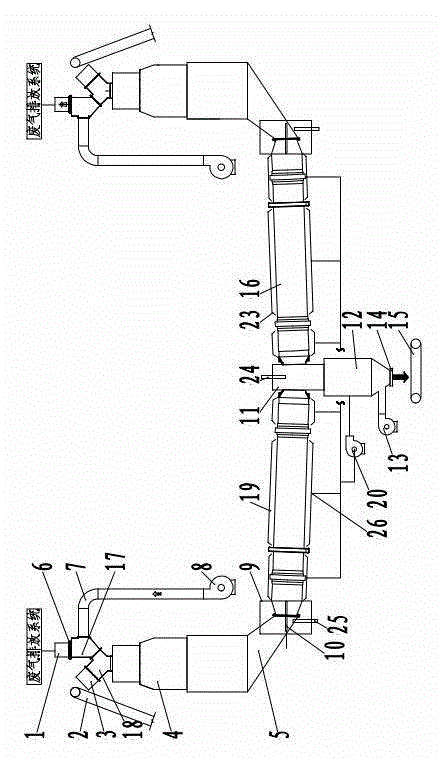

[0026] Another embodiment of the present invention is as figure 2 As shown, the kiln body 16 is provided with a waste heat recovery device 19 and an induced draft fan 20 . The waste heat recovery device 19 is a cylindrical structure, located outside each kiln body of the rotary kiln, and installed coaxially with the kiln body. The waste heat recovery device is provided with an air inlet 23 and an air outlet 26, the air inlet 23 is located on both sides of the waste heat recovery device, the outlet of the waste heat recovery device is connected to the inlet of the induced draft fan 20 through a pipeline, and the outlet of the induced draft fan is connected to the cooling chamber 12 of the middle. The heat emitted by the outer wall of the kiln is recovered by the waste heat recovery device, and the air preheated by the waste heat recovery device enters the cooling room, and the heat of the cooling product is used to continue heating the air. In the cooling chamber 12, the coo...

Embodiment 3

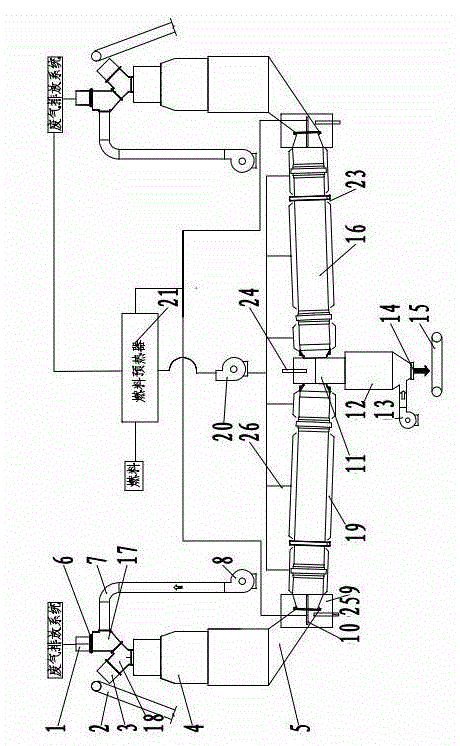

[0028] The third embodiment of the present invention is as image 3 As shown, the outlet of the induced draft fan is connected to the fuel preheater 21, the fuel pipeline passes through the fuel preheater to the burner 10, and the heat recovered by the waste heat recovery device passes through the fuel preheater 21 to preheat the fuel.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap