Processing method and processing device capable of mixing two fibers in spinning process

A fiber and spun yarn technology, used in piecing devices, spinning machines, textiles and papermaking, etc., can solve the problem of long time, improve efficiency, shorten the drawing process, and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The spacing between the output of the two whiskers 16 from the front roller 19 is set to 8mm; the draft ratio of the front roller 19 and the output roller 23 area is 0.8.

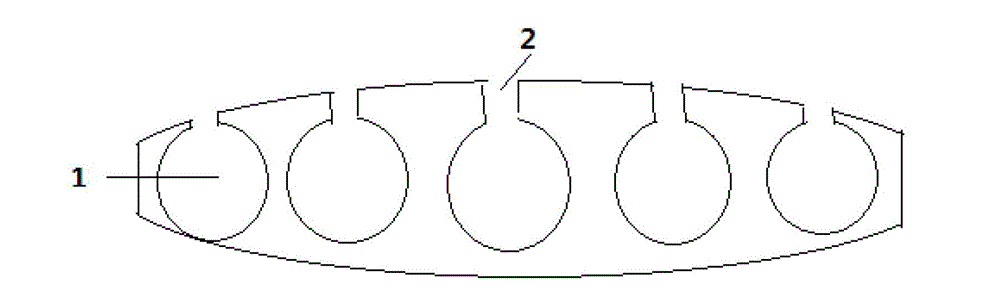

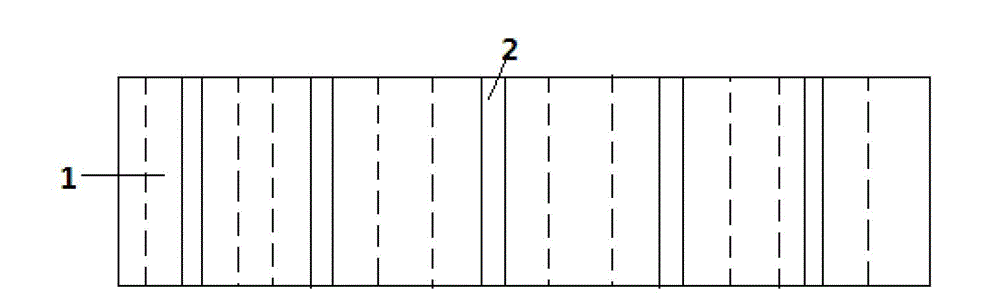

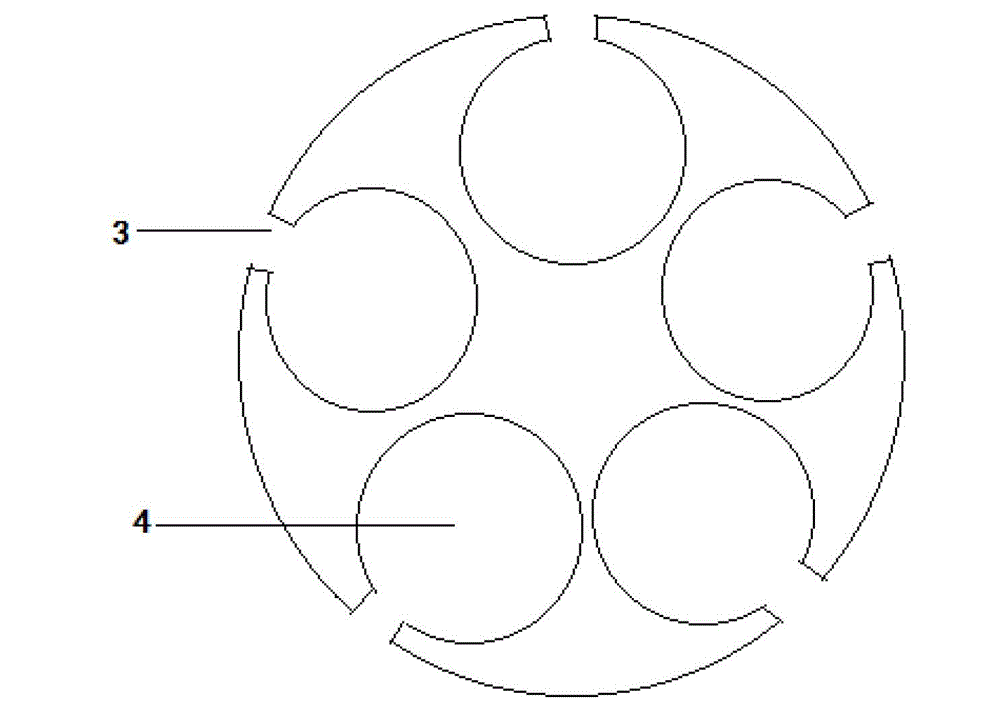

[0035]The five parallel bell mouths 20, five cylindrical five parallel bell mouth openings 1 are arranged side by side, and each opening has a gap with the outside, that is, the five parallel bell mouth opening gaps 2, which are convenient for yarns to enter. The mouth width is 8mm, the height is 1.5mm, and the length is 2mm. The diameter of the opening 1 of the cylindrical five parallel bell mouths is 1mm. The two parallel bell mouths 20 with five openings are positioned at the same angle relative to the nozzle 22 to ensure that the tensions on the two bundles of fibers are basically the same before merging. The five annular bell mouths 21 are cylindrical, with a diameter of 4mm and a length of 2mm. The diameter of each opening is 1.5mm, and each opening has a gap, which is convenient for yarn conne...

Embodiment 2

[0037] The spacing between the output of the two whiskers 16 from the front roller 19 is set to 10mm; the draft ratio of the front roller 19 and the output roller 23 area is 0.9.

[0038] The five parallel bell mouths 20, five cylindrical five parallel bell mouth openings 1 are arranged side by side, and each opening has a gap with the outside, that is, the five parallel bell mouth opening gaps 2, which are convenient for yarns to enter. The mouth width is 9.5mm, the height is 1.75mm, and the length is 2mm. The diameter of the opening 1 of the cylindrical five parallel bell mouths is 1.25mm. The two parallel bell mouths 20 with five openings are positioned at the same angle relative to the nozzle 22 to ensure that the tensions on the two bundles of fibers are basically the same before merging. The five annular bell mouths 21 are cylindrical, with a diameter of 4.25mm and a length of 2mm. The diameter of each opening is 1.75mm, and each opening has a gap, which is convenient fo...

Embodiment 3

[0040] The spacing between the output of the two strands 16 from the front roller 19 is set to 14mm; the draft ratio in the area between the front roller 19 and the output roller 23 is 0.99.

[0041] The five parallel bell mouths 20, five cylindrical five parallel bell mouth openings 1 are arranged side by side, and each opening has a gap with the outside, that is, the five parallel bell mouth opening gaps 2, which are convenient for yarns to enter. The mouth width is 11mm, the height is 2mm, and the length is 2mm. The diameter of the opening 1 of the cylindrical five parallel bell mouths is 1.5mm. The two parallel bell mouths 20 with five openings are positioned at the same angle relative to the nozzle 22 to ensure that the tensions on the two bundles of fibers are basically the same before merging. The five annular bell mouths 21 are cylindrical, with a diameter of 4.5mm and a length of 2mm. The diameter of each opening is 2mm, and each opening has a gap, which is convenient...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com