Weft knitting mechanism

A technology of weft and warp, applied in the field of weaving mechanism, can solve the problems that the service life does not reach the expected effect, damage the physical and mental health of the workers, and can not last for a long time, and achieves the improvement of labor productivity, simple structure and improved weaving quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

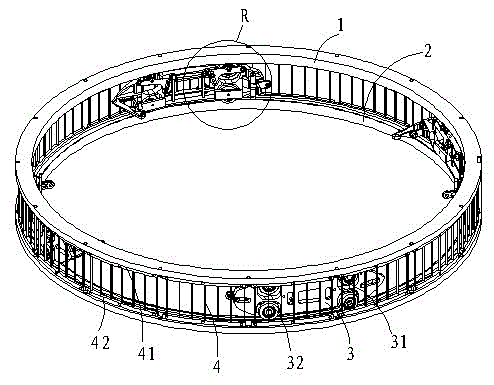

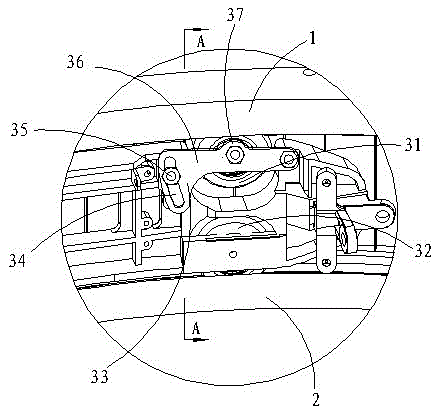

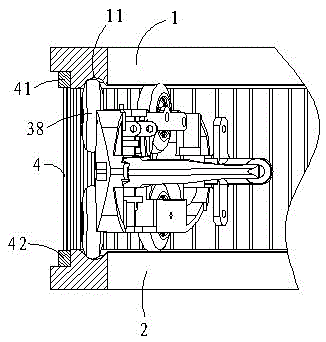

[0022] Example: A weft knitting mechanism, such as figure 1 , figure 2 , image 3 As shown, the upper door ring 1 and the lower door ring 2 are included. The outer edges of the upper door ring 1 and the lower door ring 2 are respectively provided with steps formed by removing materials. The upper door ring 1 is fastened with an upper fixing strip 41 and the lower door A lower fixing strip 42 is firmly connected in the step of the ring 2, and the upper fixing strip 41 and the lower fixing strip 42 are connected by a plurality of dividing strips 4 made of iron wire, and the plurality of dividing strips 4 are arranged in parallel and equidistant, and the upper door ring 1. The opposite sides of the lower door ring 2 are respectively provided with an annular circular arc concave surface 11, the arc concave surface 11 is offset to the inner circumferential surface of the upper door ring 1 and the lower door ring 2, and the circular arc concave surface 11 is respectively opposite to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com