Continuous squeezing force deviation-eliminated roller using atmospheric pressure as squeezing power

A technology of atmospheric pressure and pressing force, which is applied in the processing of textile materials, liquid/gas/vapor textile material processing, liquid/gas/vapor removal by suction method, etc. It can solve the problems of large pollution, high cost, and impact on human health. , to achieve the effect of continuous production operation, good effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

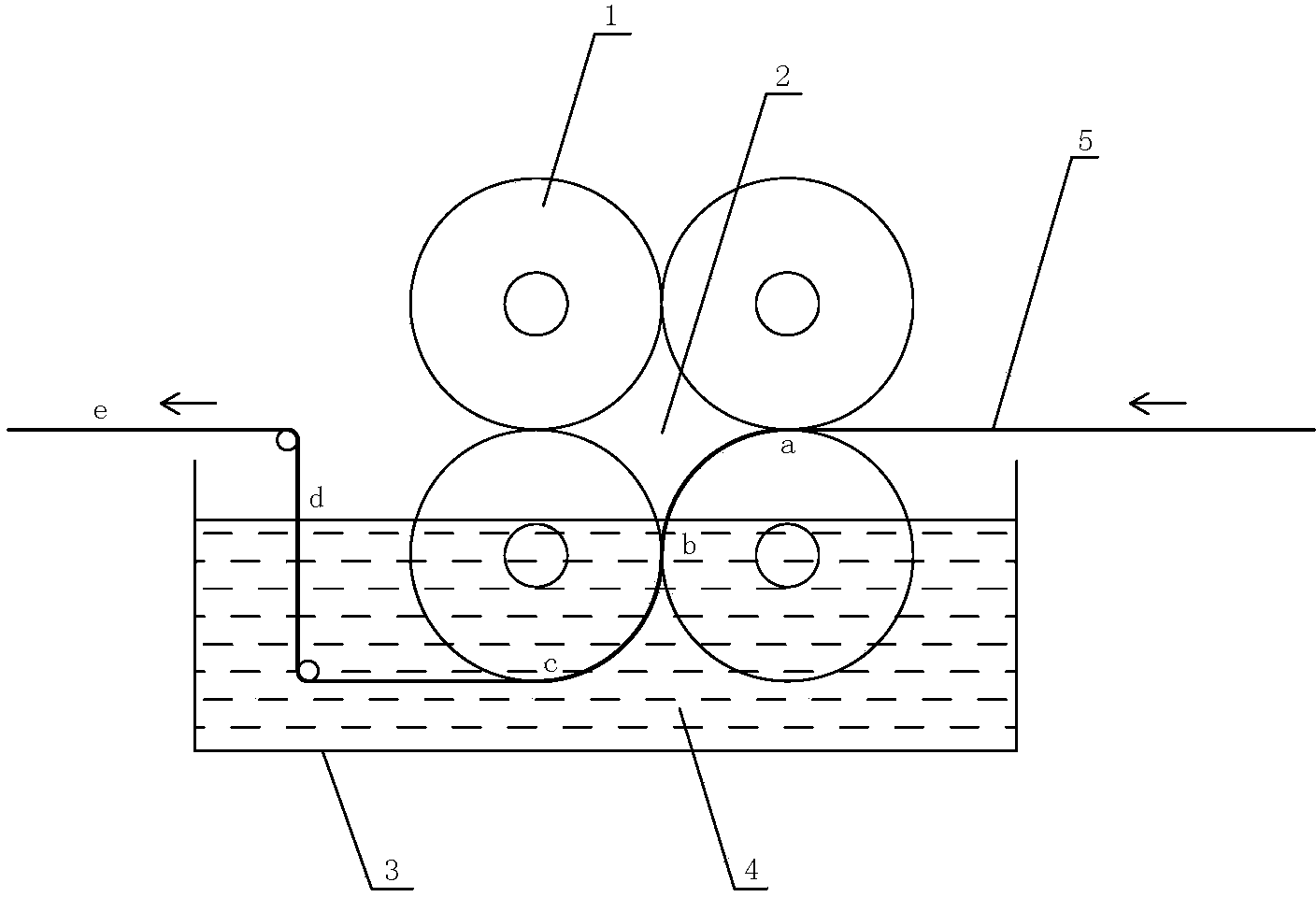

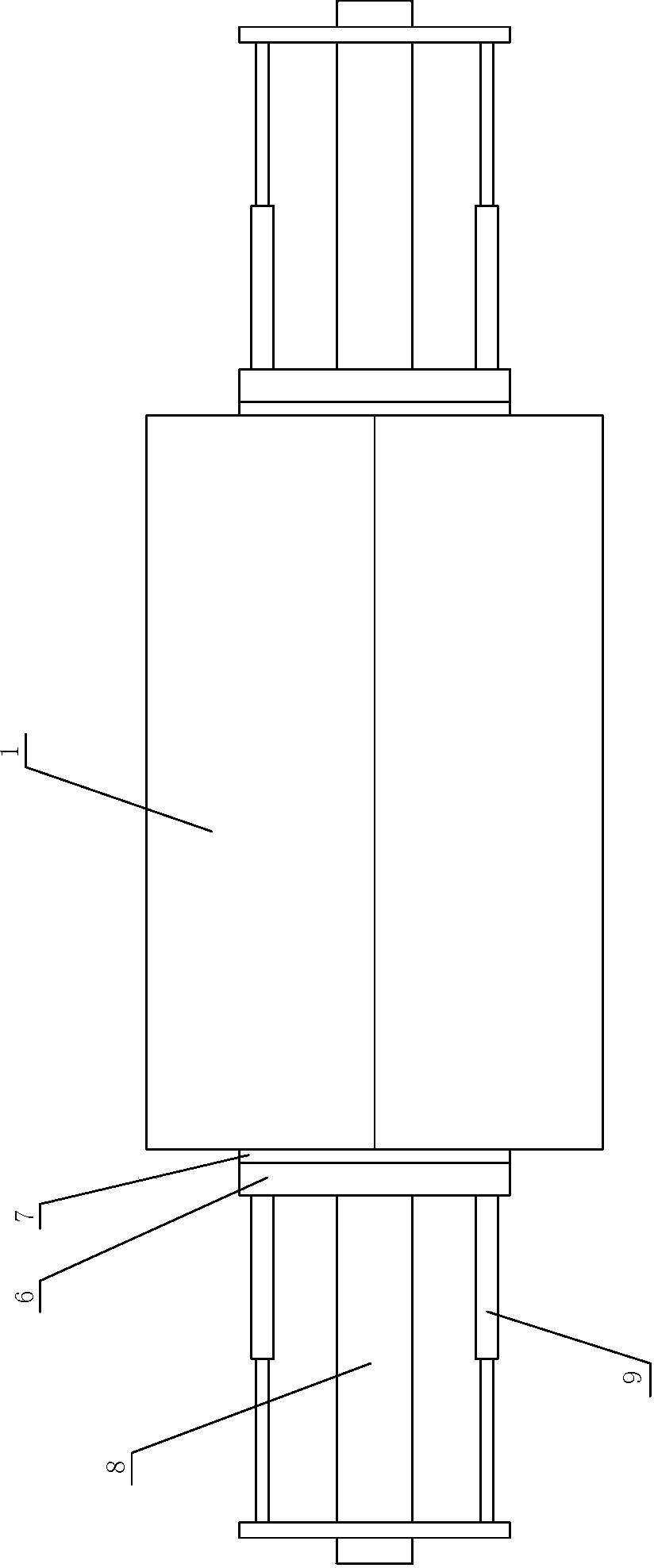

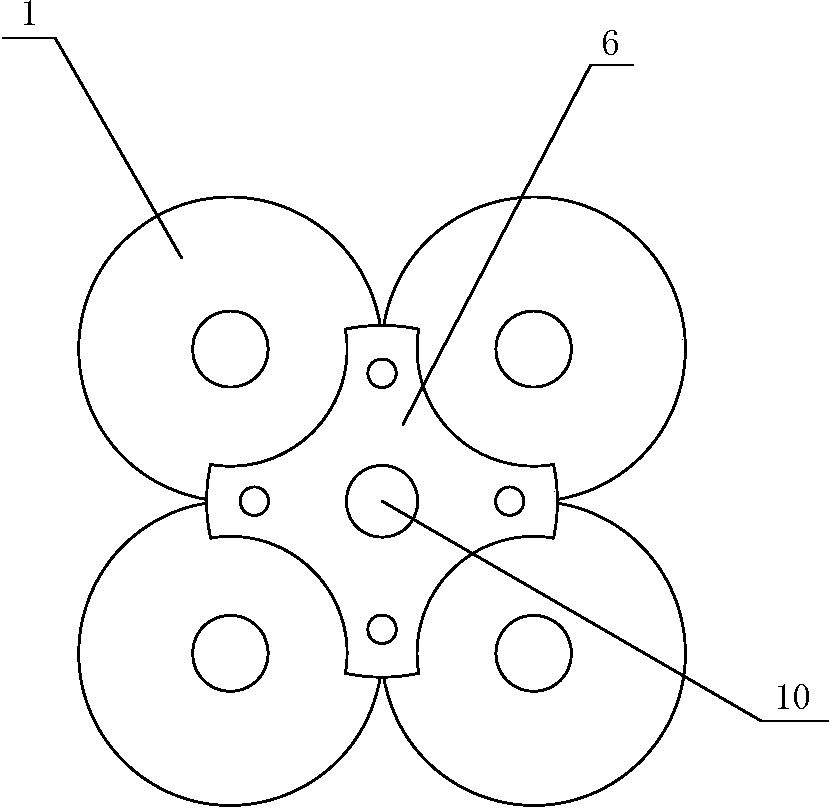

[0027] See Figure 1~Figure 3 The illustrated embodiment, in this embodiment, the continuous non-deviation rolling rolls with atmospheric pressure as the pressing power include at least four rolls 1, the four rolls 1 are arranged in a square, and the two ends of the rolls 1 are respectively provided with sealing baffles 6 A sealed cavity 2 is formed between the roller 1 and the sealing baffle 6, and the sealing baffle 6 on at least one side is provided with an air extraction port 10; the lower part of the roller 1 is provided with a main water tank 3, and water 4 is accommodated in the main water tank 3. The shape of the sealing baffle 6 matches the shape of the cross-section of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com