Composite sheet structure and manufacturing method thereof

A technology of composite board and manufacturing method, which is applied in the direction of building components, building structures, buildings, etc., can solve the problems of poor toughness and strength, and can not better achieve lightweight and structural strengthening, and achieve the effect of strengthening strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following will refer to the related drawings to illustrate the embodiments of the composite plate structure and its manufacturing method according to the present invention. For easy understanding, the same components in the following embodiments are described with the same symbols.

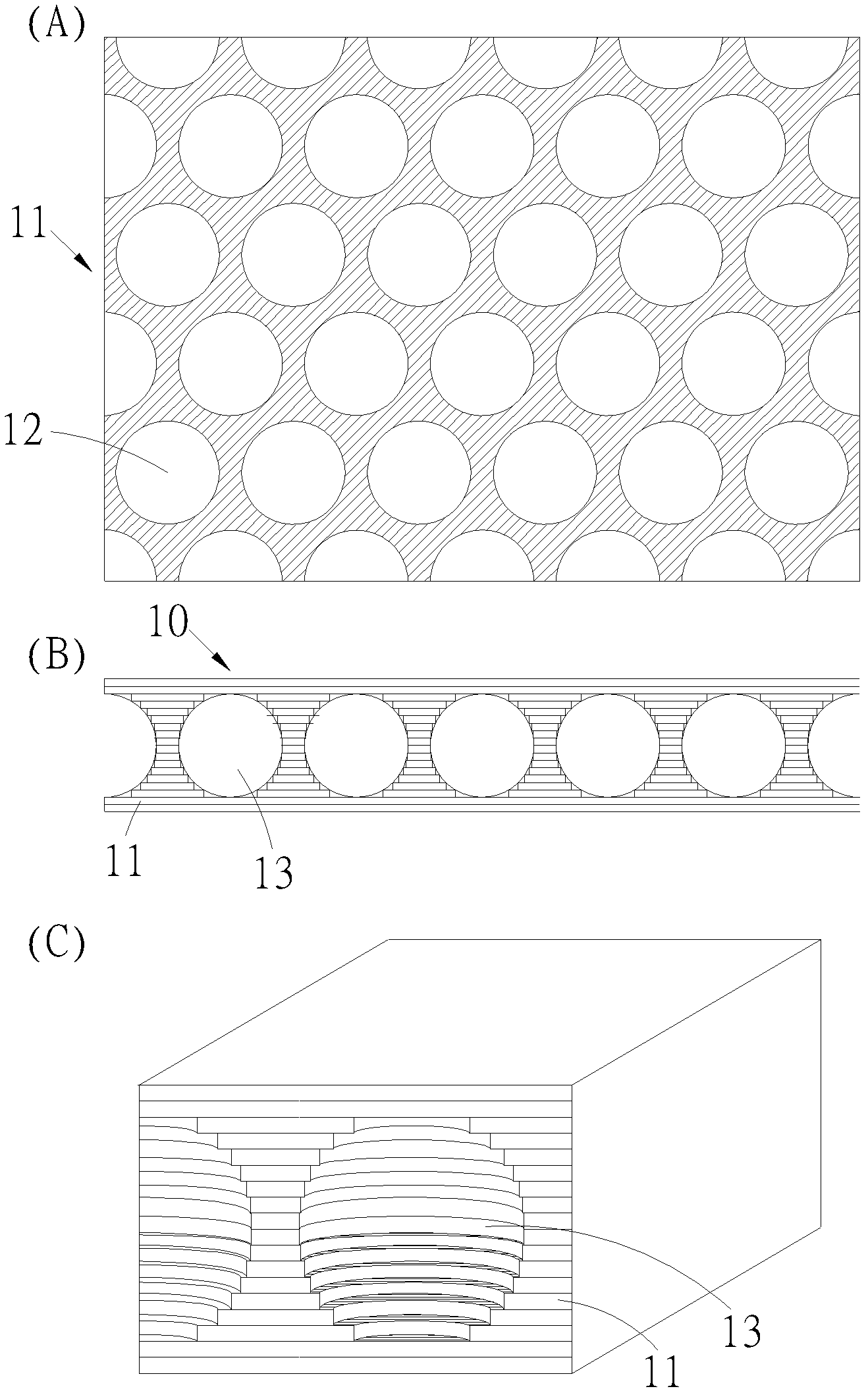

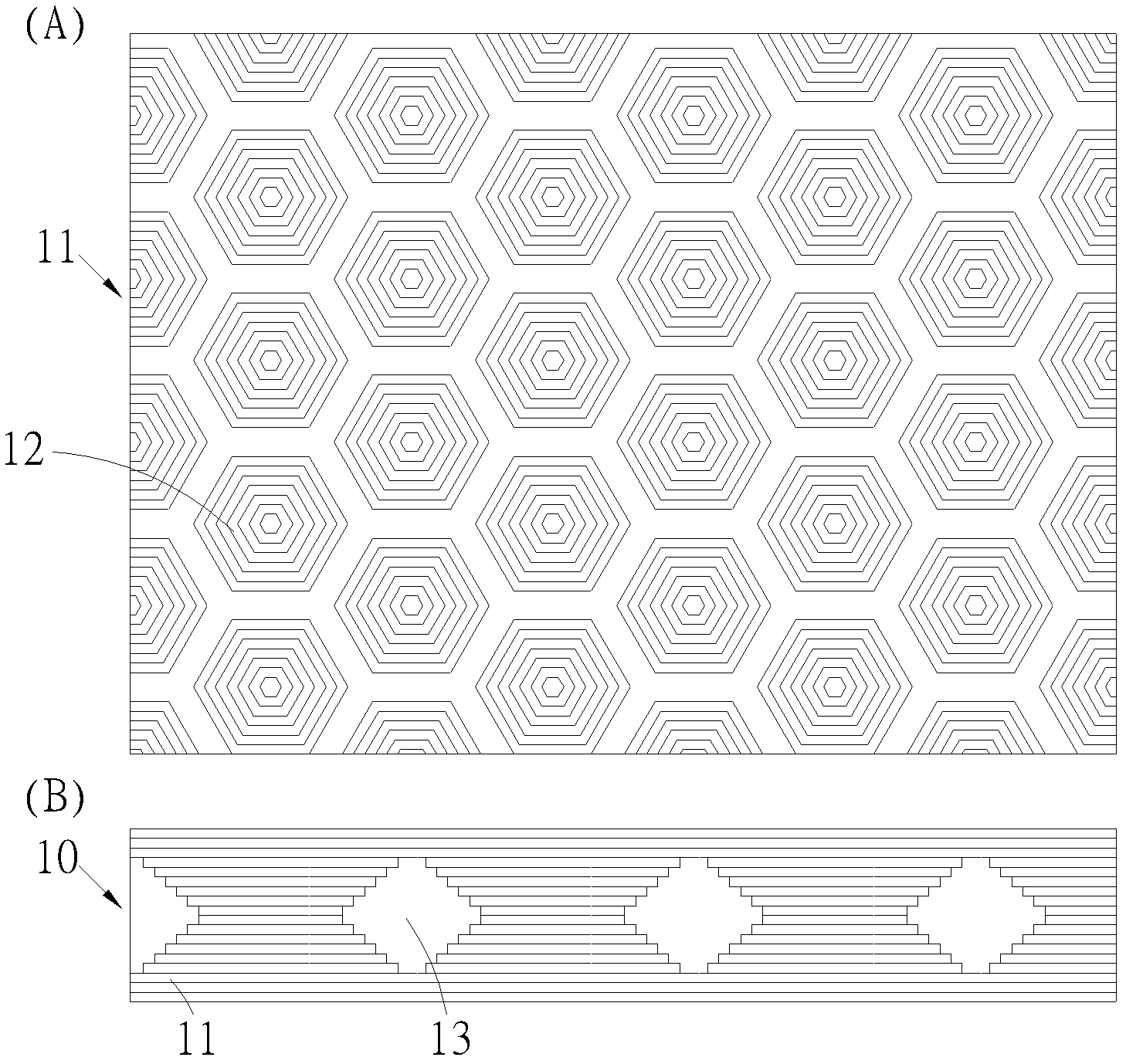

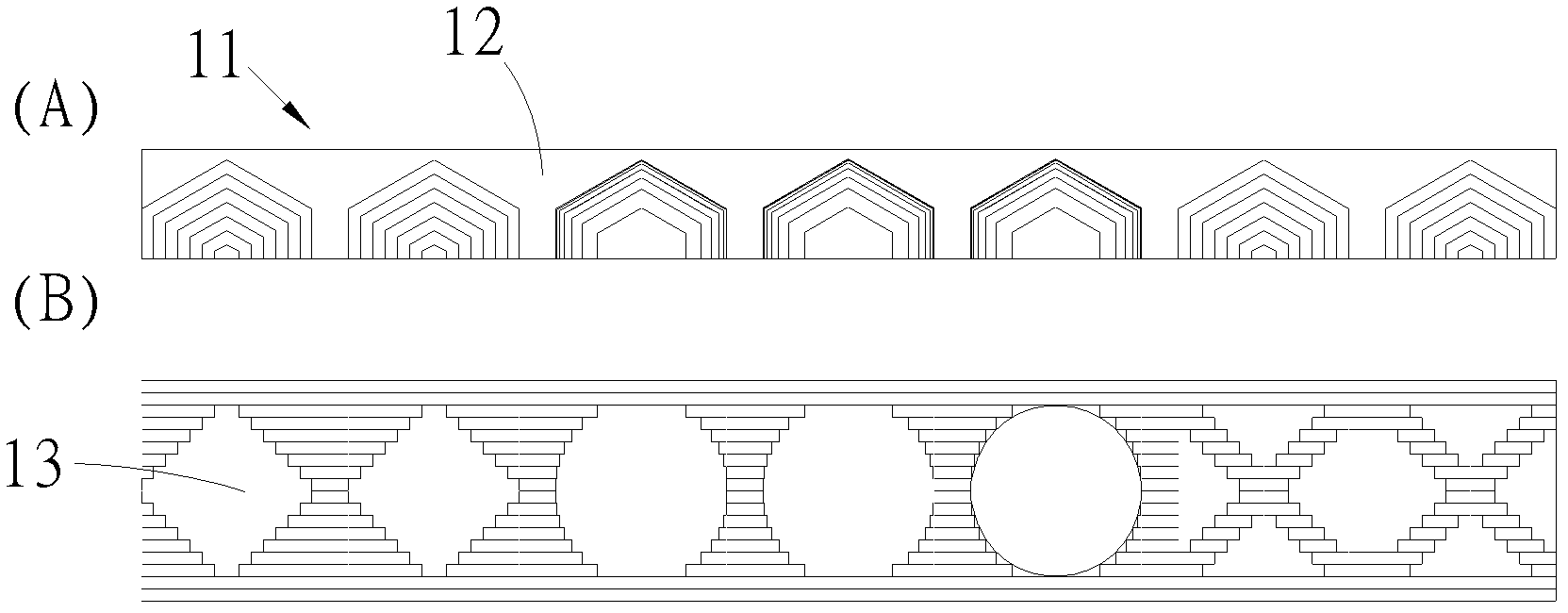

[0041] see figure 1 ,in figure 1 (A) is the schematic diagram of the first embodiment of the plate of the composite plate structure of the present invention, figure 1 (B) and figure 1 (C) are respectively a longitudinal section view and a partial longitudinal section perspective view of the first embodiment of the composite plate structure of the present invention. Such as figure 1 As shown in (A), it is a schematic diagram of one of the plates 11 of the composite plate structure 10 , and the plate 11 has a plurality of holes 12 . exist figure 1 In (B), the composite plate structure 10 of the present invention is formed by stacking a plurality of plates 11 , and the composite plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com