Light source mechanism capable of moving along spherical track

A technology of spherical motion and light source, applied in the field of mechanical structure, can solve the problems of inability to irradiate equipment in real time and guarantee equipment, and achieve the effect of consistent illuminance and flexible positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

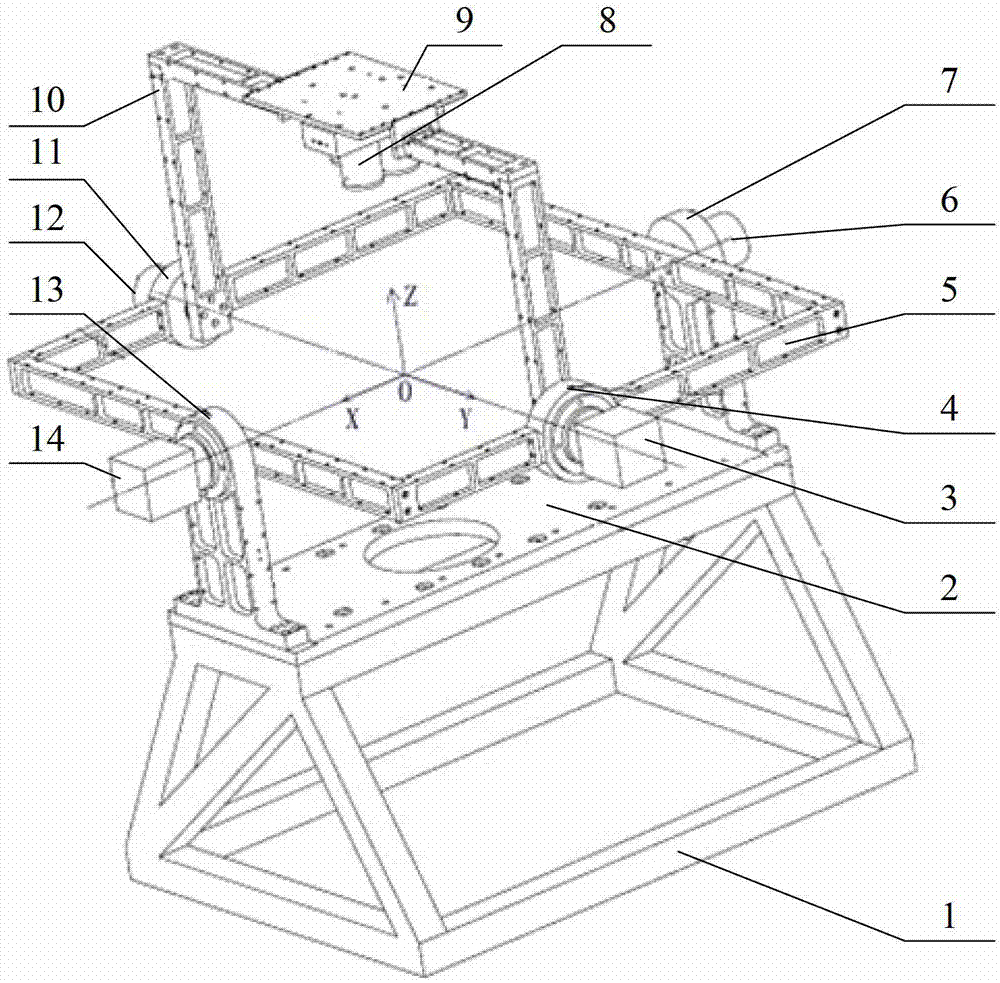

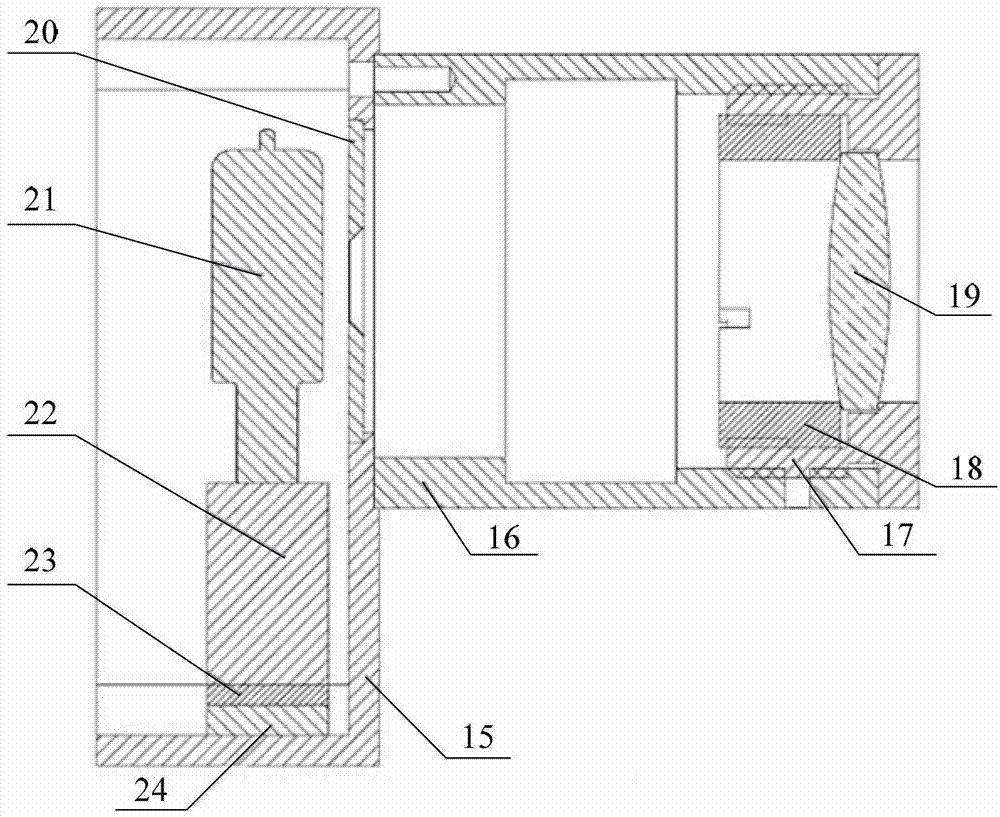

[0020] See attached figure 1 , 2 The light source mechanism of the present invention includes a two-dimensional motion mechanism and a light source assembly 8 capable of emitting parallel light. Frame driven end shaft system 7, outer frame motor-reducer 14, outer frame encoder 6, inner frame 10, inner frame driving end shaft system 4, inner frame driven end shaft system 11, inner frame motor-reducer 3 , an inner frame encoder 12, a light source mounting plate 9; the stage 2 and the bottom bracket 1 are connected by bolts, the outer frame driving end shaft system 13 and the outer frame driven end shaft system 7 are fixed on the object stage 2, The outer frame motor-reducer 14 is fixed on the outer frame driving end shafting 13, the outer frame encoder 6 is fixed on the outer frame driven end shafting 7, and the inner frame 10 passes through the inner frame driving end shafting 4 and the inner frame driven end The shaft system 11 is connected to the outer frame 5, and the ligh...

Embodiment 2

[0025] The outer frame 5 of the two-dimensional motion mechanism is a 630mm×702mm square frame, and the inner frame 10 is a half frame of 650mm×340mm. The inner frame 10 and the outer frame 5 are larger in size, and because the load is smaller, in order to save manufacturing costs, the inner frame 10 and the outer frame 5 are spliced by straight aluminum alloy plates. The four shaft systems of the mechanism all use paired angular contact ball bearings with an outer diameter of 42mm, and the shaft material is 40Cr. The motor-reducer assembly selects a 42-type motor, which is matched with a planetary reducer to achieve a reduction ratio of 100 times and provide a maximum torque of 50N.m. The encoder selects a 14-bit absolute hollow shaft encoder to ensure the accuracy of rotation measurement. During installation, the main and driven end shafting of the outer frame and the main and driven end shafting of the inner frame are assembled first, and then the main and driven end sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com