Semi-automatic device for radiating fin

A detection device and a semi-automatic technology, applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, can solve the problems of high labor intensity for operators, difficulty in increasing production, and easy damage to threads, etc., to speed up inspection time, reduce use, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

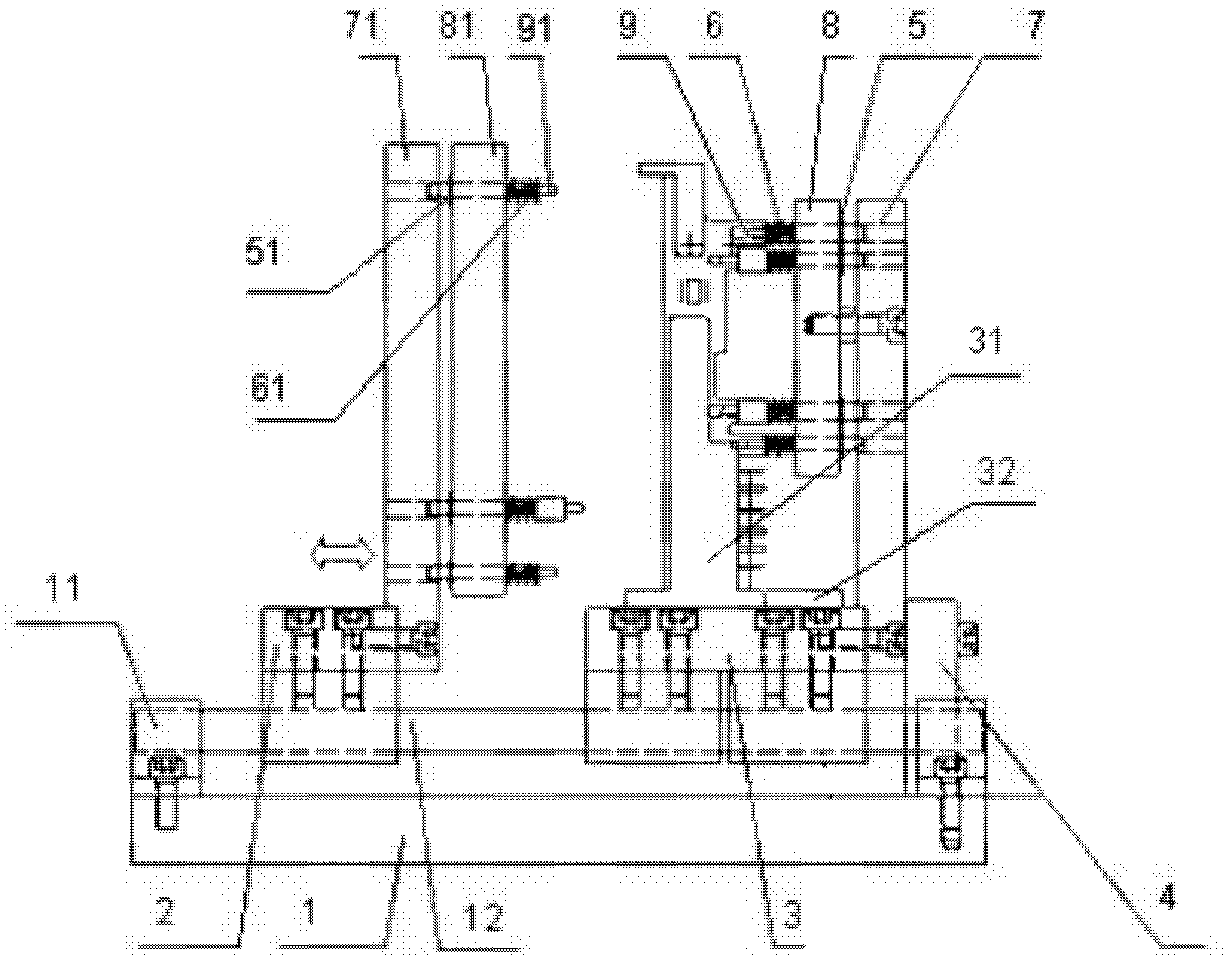

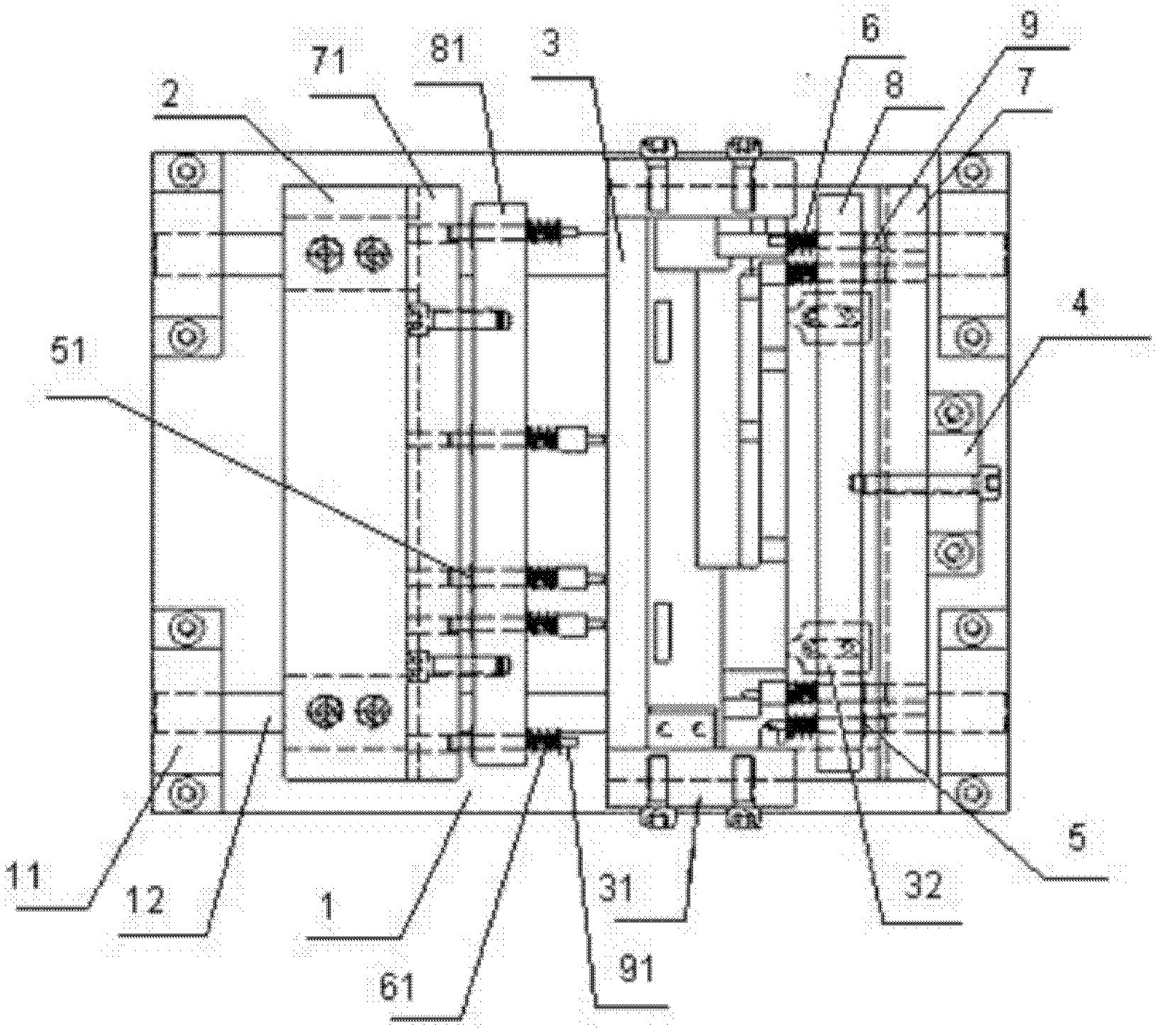

[0021] Such as figure 1 , 2 As shown, a heat sink semi-automatic detection device, the base plate 1 is provided with two pairs of guide shaft support 11, the guide shaft 12 is installed on the base plate 1 through the guide shaft support 11, the mobile base 2 is arranged on the guide shaft 11, the opposite side The support plate 71 on the detection assembly is fixed on the mobile base 2 by screws, and the side of the support plate 71 close to the workpiece base 3 is connected to the reference plate 81 by screws, and the detection column 91 passes through the reference plate 81 and is fixed on the support plate 71. Ring 51 is located on the detection column 91 between reference plate 81 and support plate 71, and is close to reference plate 81, and spring 61 is located on the detection column 91 near column head place, and each detection column is provided with a contact switch, and with An indicator lamp is connected to form an indicator circuit, and the on-off of the indicato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com