Automatic-feed detection device for melt crystal solid and liquid interface position and detection method thereof

A solid-liquid interface and detection method technology, which is applied in the field of crystal manufacturing, can solve problems such as safety hazards and sealing failures, and achieve the effects of high safety, high accuracy, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

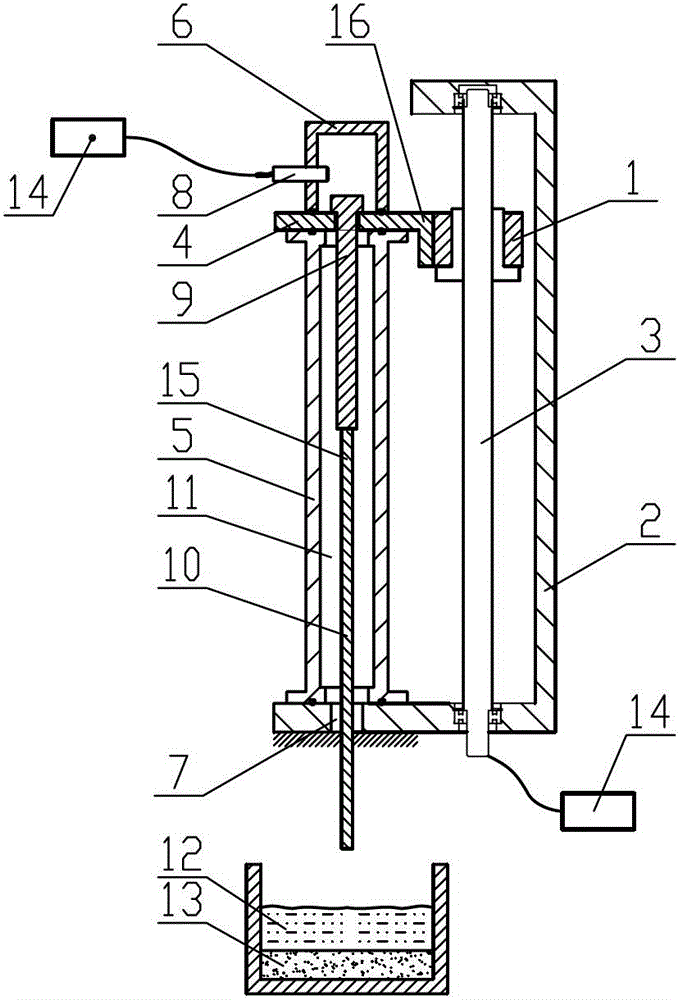

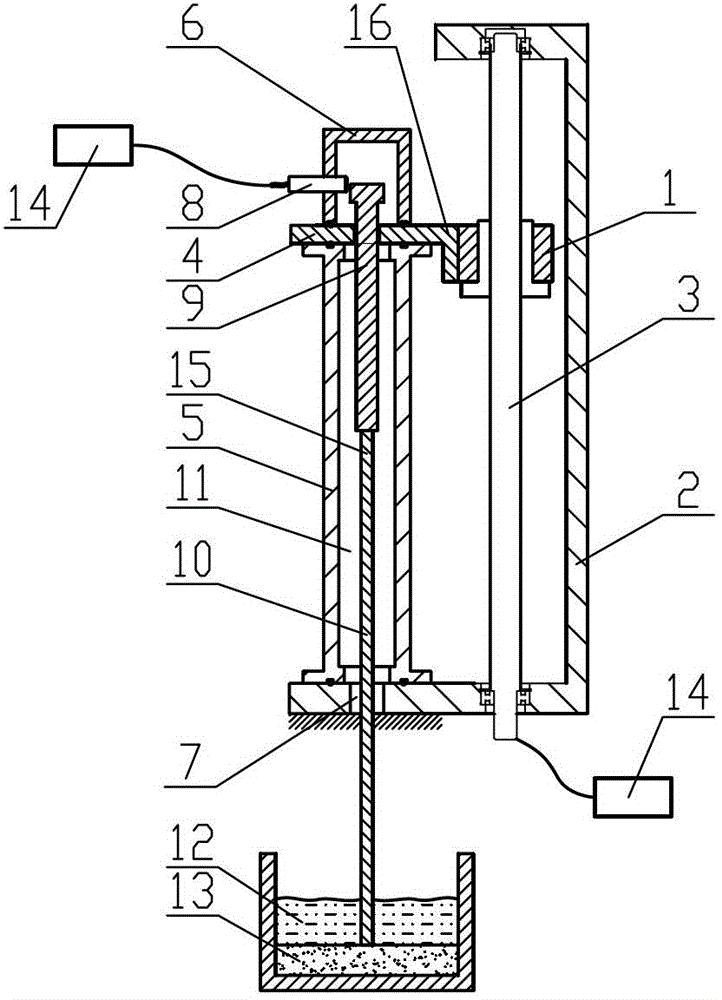

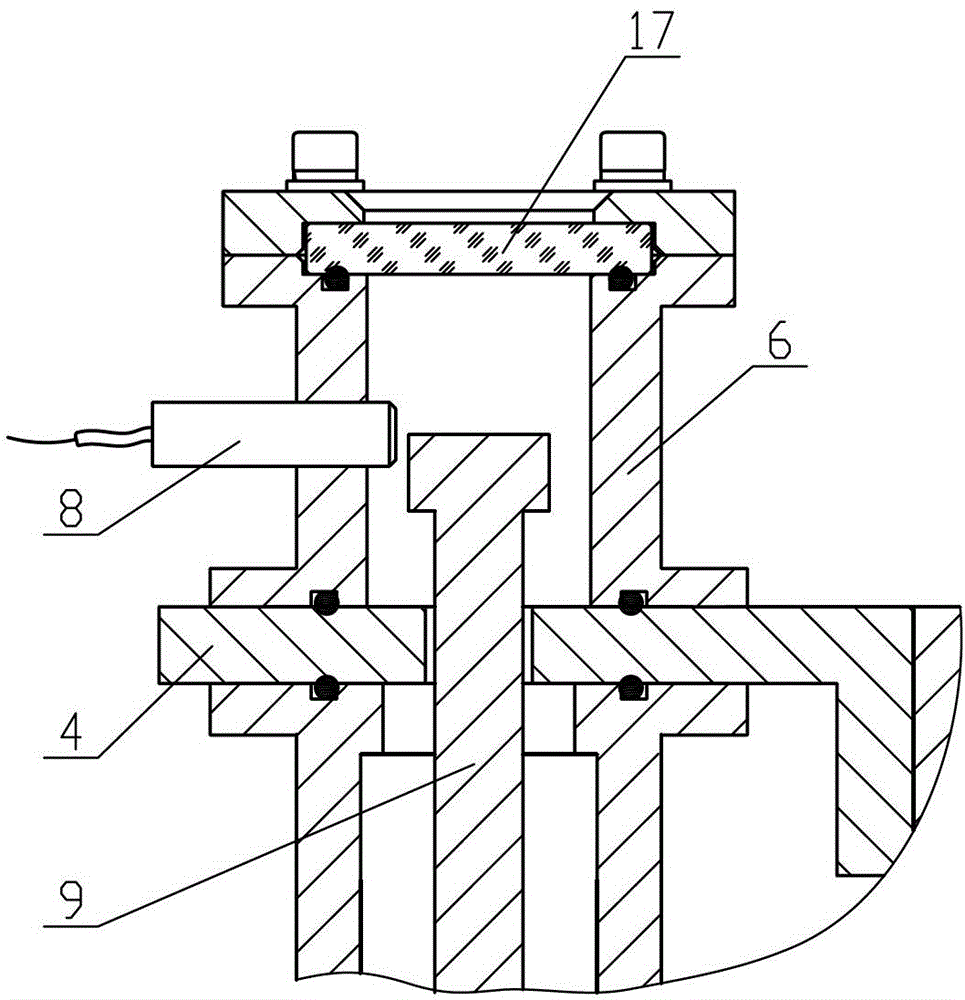

[0026] Such as Figure 1-2 In the detection device shown, the base 2 is equipped with a rotatable drive rod 3, and the drive rod 3 is provided with a slider 1 that moves up and down vertically with the rotation of the drive rod, and one side of the slider 1 is connected to a support linked with it. 4. A measuring stick 15 with the upper part suspended on the support is installed on the support 4. The measuring stick 15 is composed of a detachable rod 9 and a detection rod 10. The rod 9 is in a "T" shape, and the upper part is suspended on the On the support, the lower part is connected with the upper part of the detection rod.

[0027] The bottom of the base 2 is provided with a through hole 7 for the lower part of the measuring rod to pass through; the displacement sensor 8 is linked with the support 4, and a telescopic tube 5 for sealing and isolation is provided between the support and the base. The two end surfaces of the telescopic tube 5 are respectively sealed with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com