Density gradient array

A density gradient and array technology, applied in the field of new density gradient arrays, can solve the problems of time-consuming, laborious and inefficient configuration and calibration, and achieve the effect of improving the preparation efficiency

Active Publication Date: 2013-01-16

INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

View PDF3 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This type of density gradient meter can test one or more samples at a time during use. Since the density gradient liquid needs to be configured separately, the density gradient of each density gradient tube is different, and must be calibrated separately, while th

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

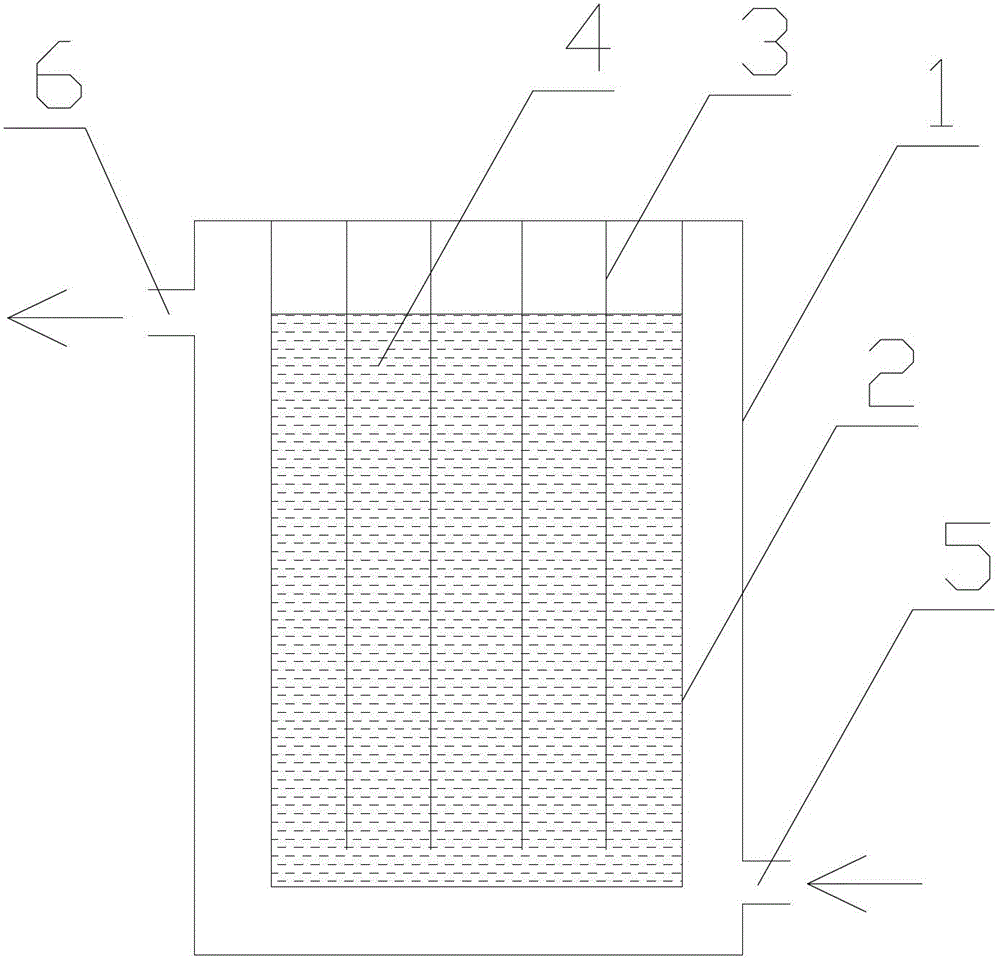

The invention discloses a density gradient array, which comprises a container. Division bars are arranged in a vertical direction in the container, and divide the container into a plurality of small tubular chambers in the vertical direction. The theory of communicating vessels is adopted, and a plurality of density tubes with a completely consistent density gradient can be prepared at one time to form an array, so that the preparation efficiency of the density tubes is greatly improved. The gradients of the density tubes are completely consistent, and the density gradient of the whole density gradient array can be calibrated only by once calibration, so that a calibration process is greatly simplified. The density tubes form the array which is suitable for the rapid measurement of large batches of samples, the density gradients of the density tubes are consistent, and subtle density differences between a plurality of different samples can be easily and intuitively compared, so that the density gradient array is particularly applied to application places with requirements for the precision comparison of densities of the samples, for example, subtle changes caused by changes in a crystallization environment in the densities of the samples in a high-quality crystal development process can be monitored.

Description

technical field [0001] The invention belongs to the field of instrument design and manufacture, and in particular relates to a novel density gradient array. Background technique [0002] The density gradient method is an important method for testing the density of solid materials. Compared with the dipping method and the float-sink method, the density gradient method has the advantages of high measurement accuracy, easy operation and wide measurement range. It is used in biomedicine, chemical industry, etc. field has been widely used. At present, there are corresponding density gradient instruments on the market, most of which are composed of single or multiple independent density gradient tubes. This type of density gradient meter can test one or more samples at a time during use. Since the density gradient liquid needs to be configured separately, the density gradient of each density gradient tube is different, and must be calibrated separately, while the density gradient...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N9/00

Inventor 康彬徐瑞娟姜燕黄辉刘渝马军

Owner INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com