Recovery performance analysis method for car products

An analysis method, the technology of the car, applied in the field of analysis of the recycling performance of the car product, can solve the problems of seldom considering the recycling process of the product, low recycling rate, and poor recycling economy, so as to reduce the design cost and test cost, and shorten the research and development time , Improve the effect of recycling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

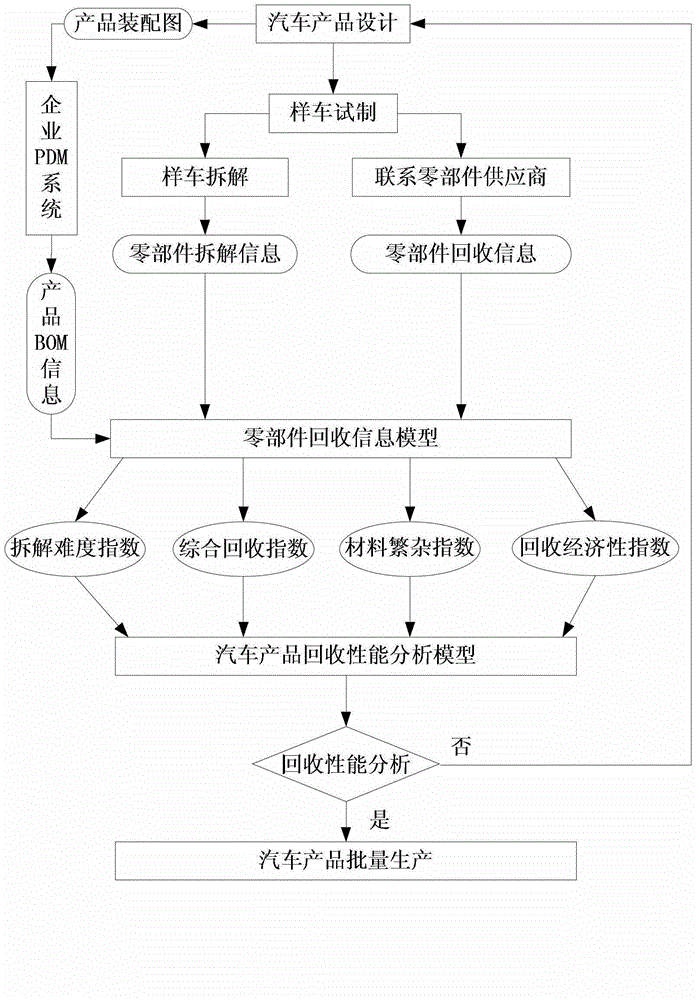

[0030] Through the method in the present invention, after the design of the car product is completed and before it is put into production, that is, in the trial production stage of the prototype vehicle, the recovery performance analysis of the car product can be completed, the design of the product can be improved, the recovery performance can be improved, and the prediction of the recovery performance of the car product can be realized. Change the traditional design and production first and then analyze the recycling performance into parallel design and recycling performance analysis, which shortens the design and development time of car products, reduces the design cost and test cost, and improves the response of automobile companies to foreign market-related access systems and regulations. The ability of relevant domestic regulations and policies.

[0031] Such as figure 1 Shown is a flow chart of a method for analyzing the recycling performance of a car product.

[0032]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com