Fine management method for steel ladles of steel plant

A technology of refined management and steelmaking plant, applied in the field of ladle management in steelmaking plants, it can solve the problems of low ladle turnover rate, confusion, and large number of ladles, etc., and achieve the effect of improving the level of refined management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

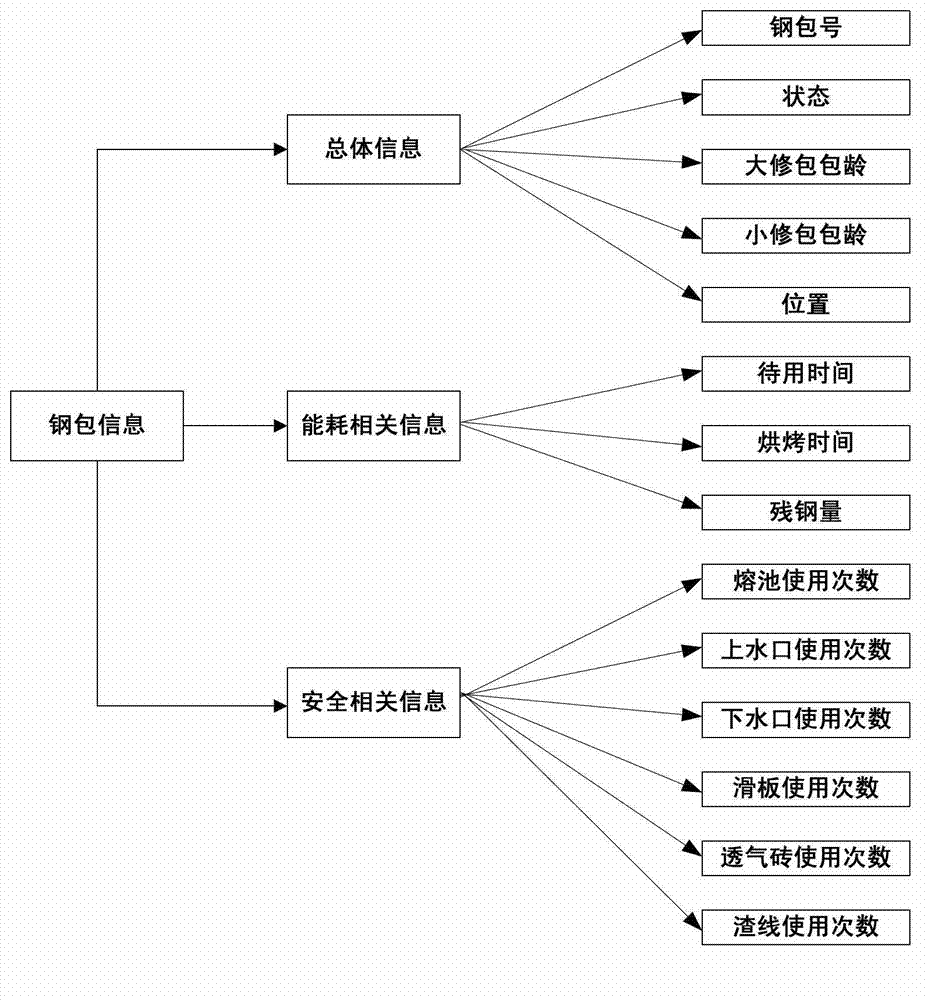

[0077] Production plan and ladle information

[0078] (1) The dispatcher obtains the current production plan, which includes information such as smelting steel type, tapping time and furnace number, as follows:

[0079] steel type

Tapping time

heat number

Is it the first batch

Refining method

MGW800

2012-7-26 12:30:33

12400001

yes

RH

[0080] (2) The dispatcher obtains all ladle information, these states include: running, standby, online baking, offline baking and offline maintenance. Select the standby and online baking ladle as the alternative ladle, as follows:

[0081]

[0082] (3) The dispatcher selects a steel ladle as the running ladle, and sets the upper limit of the use times of the molten pool to 138, the upper limit of the use times of the upper nozzle to 10, the upper limit of the use times of the lower nozzle to 4, the upper limit of the use times of the slide plate to 4, and the ventilation brick Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com