Welding workload calculating method

A calculation method and workload technology, applied in welding equipment, welding medium, welding equipment, etc., can solve problems such as unreasonable production planning, unsatisfactory welding performance, and failure to achieve refined management of enterprises, so as to improve refined management horizontal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand and implement, the patent of the present invention will be described in detail with specific embodiments given below in conjunction with the accompanying drawings.

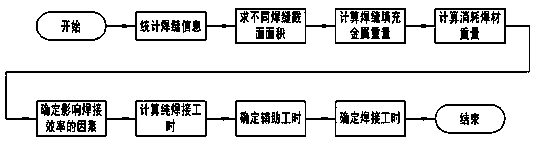

[0026] Such as figure 1 , 2 Shown; a welding workload calculation method, including the following steps:

[0027] 1. Statistics of weld seam information: number the weld seam, determine the identity information of the weld seam, including the identity information of the weld seam; count the shape of the weld groove, the length of the weld seam, the welding process number, the material of the base metal, the thickness of the base metal, Welding position, working environment, and NDT method form the "Weld Statistical Table";

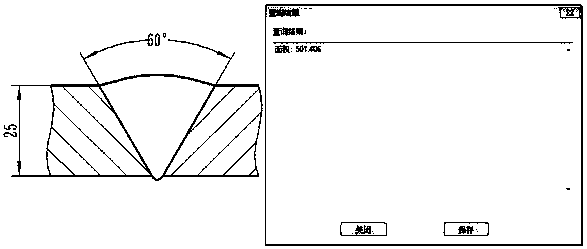

[0028] 2. Calculate the cross-sectional area of the weld: draw all the cross-sectional shapes of the weld through CAD drawing, use the CAD calculation area function to calculate the cross-sectional area of all shapes of the weld, and enter the data of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com