Gas-permeable film, manufacturing method therefore, and packaging bag using said gas-permeable film

A manufacturing method and gas-permeable technology, applied in packaging, wrapping paper, exhaust devices, etc., can solve problems such as the infiltration of seasoning liquid and the disappearance of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

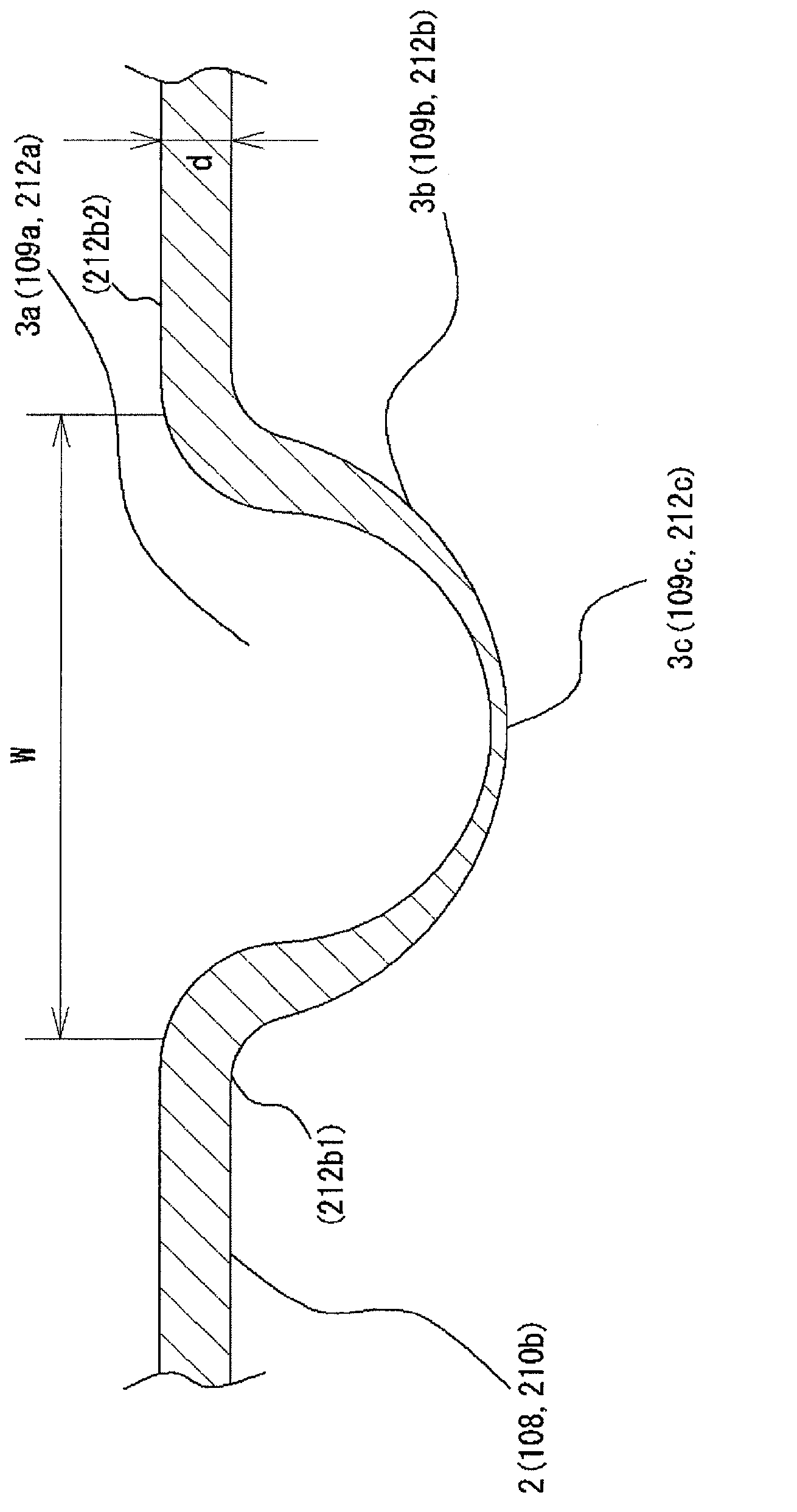

[0271] In the air-permeable film of the present invention, a film substrate including a plastic film having a specific thickness is provided with an air-permeable portion through which gas can pass. The air-permeable part includes a concave part, which is convex from one side to the other side in the length direction of the film substrate, and the bottom is convex from the other side to the outside. The opening portion of the opening gradually becomes thinner toward the bottom and the bottom is formed thinnest. The recess includes a specific shape of a slot or a concave hole or the like.

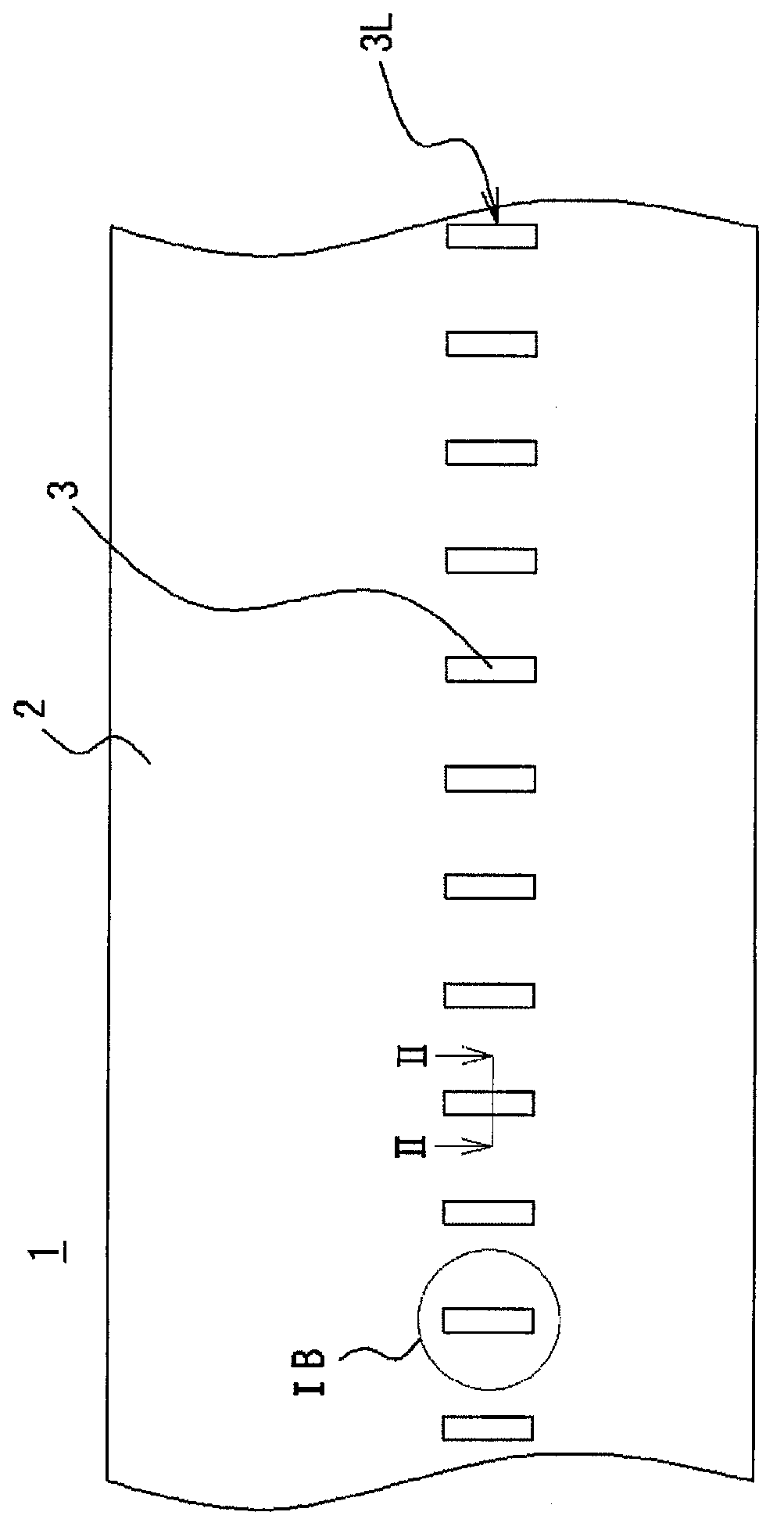

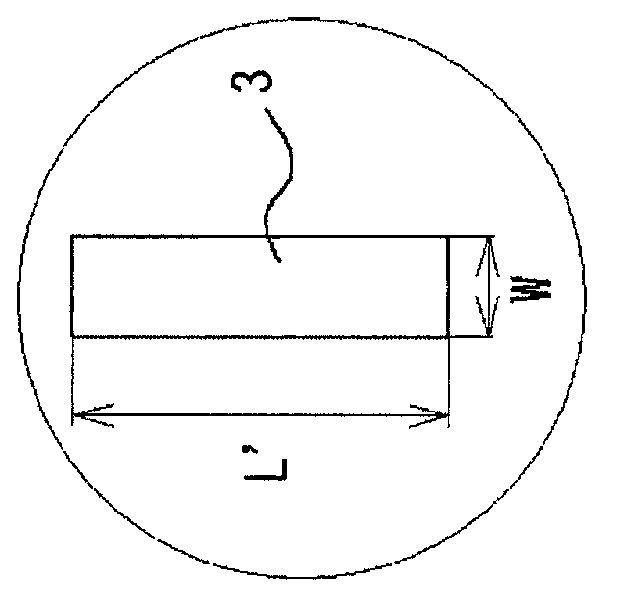

[0272] Below, referring to Figure 1, figure 2 The air-permeable film according to Embodiment 1 of the present invention will be described. In addition, FIG. 1 shows a breathable film according to Embodiment 1 of the present invention, Figure 1A is the floor plan, Figure 1B is an enlarged view of part IB of Figure 1, figure 2 It is a sectional view taken along line II-II in FIG. 1 . ...

Embodiment approach 2

[0294] The air permeable film 1 according to Embodiment 1 of the present invention has been described using a film in which a plurality of slits 3 are arranged approximately in parallel at predetermined intervals, but the present invention is not limited thereto, and other arrangements and shapes are not required. in addition, Figure 5 It is a plan view of the air-permeable film of other Embodiment 2.

[0295] In the air-permeable film 1A, an imaginary line L is drawn in the longitudinal direction of the film substrate 2, and a plurality of slits 3A are arranged at predetermined intervals along the line to form a slit group 3AL. In the air-permeable film 1B, a virtual line L is drawn in the longitudinal direction of the film base material 2, and a plurality of slits 3B are arranged to intersect the line to form a slit group 3BL. In addition, in the air-permeable film 1C, a plurality of mountain-shaped slits are arranged on the imaginary line L at predetermined intervals to f...

Embodiment approach 3

[0297] A gas-permeable film according to still another third embodiment of the present invention and a method for producing the same will be described with reference to FIGS. 6 and 7 . 6 is an enlarged cross-sectional view of a slit portion where other films are laminated on either the front and back surfaces of the film provided with slits, and FIG. 7 is a schematic view of a manufacturing apparatus for manufacturing the air-permeable film of FIG. 6 .

[0298] The air-permeable film 10 is formed by bonding other films with an adhesive to the protruding side of the film 11 provided with the slit S. The slot S has the same structure as the slot 3, and the wall thickness gradually becomes thinner from the upper opening groove 11a to the bottom, and is raised into a mountain shape, so that the bottom protrudes outward from the other surface, and the bottom 11c is the thinnest. As a result, the cross-sectional shape is substantially U-shaped or V-shaped.

[0299] Examples of comb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com