Novel quinacridone pigment composition, and process for production of quinacridone microparticles

A pigment composition, quinacridone technology, applied in the direction of thin material processing, organic dyes, nanotechnology for materials and surface science, etc., can solve the problem of undisclosed methods, transparency, spectroscopic characteristics, and durability characteristics. Appearance, great energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0098] Regarding the present invention, an example in which the following quinacridone microparticles were produced by using the apparatus of the applicant of the present application, which is based on the same principle as that described in Patent Document 3: in the transmission spectrum in the range of 350 to 800 nm The difference between the highest (Tmax1) and the lowest (Tmin) transmittance (Tmax1-Tmin) is more than 80% of quinacridone particles, and the highest (Tmax2) and minimum (Tmin) transmittance in 350-580nm The difference (Tmax2-Tmin) is more than 30% of quinacridone particles, and the difference between the highest (Tmax 1) and the lowest (Tmin) of the transmittance (Tmax1-Tmin) in the transmission spectrum in the range of 350-800nm It is 80% or more, and the wavelength (λmax) at which the transmittance reaches the highest in 350 to 500 nm is less than 430 nm. However, the present invention is not limited to the following examples.

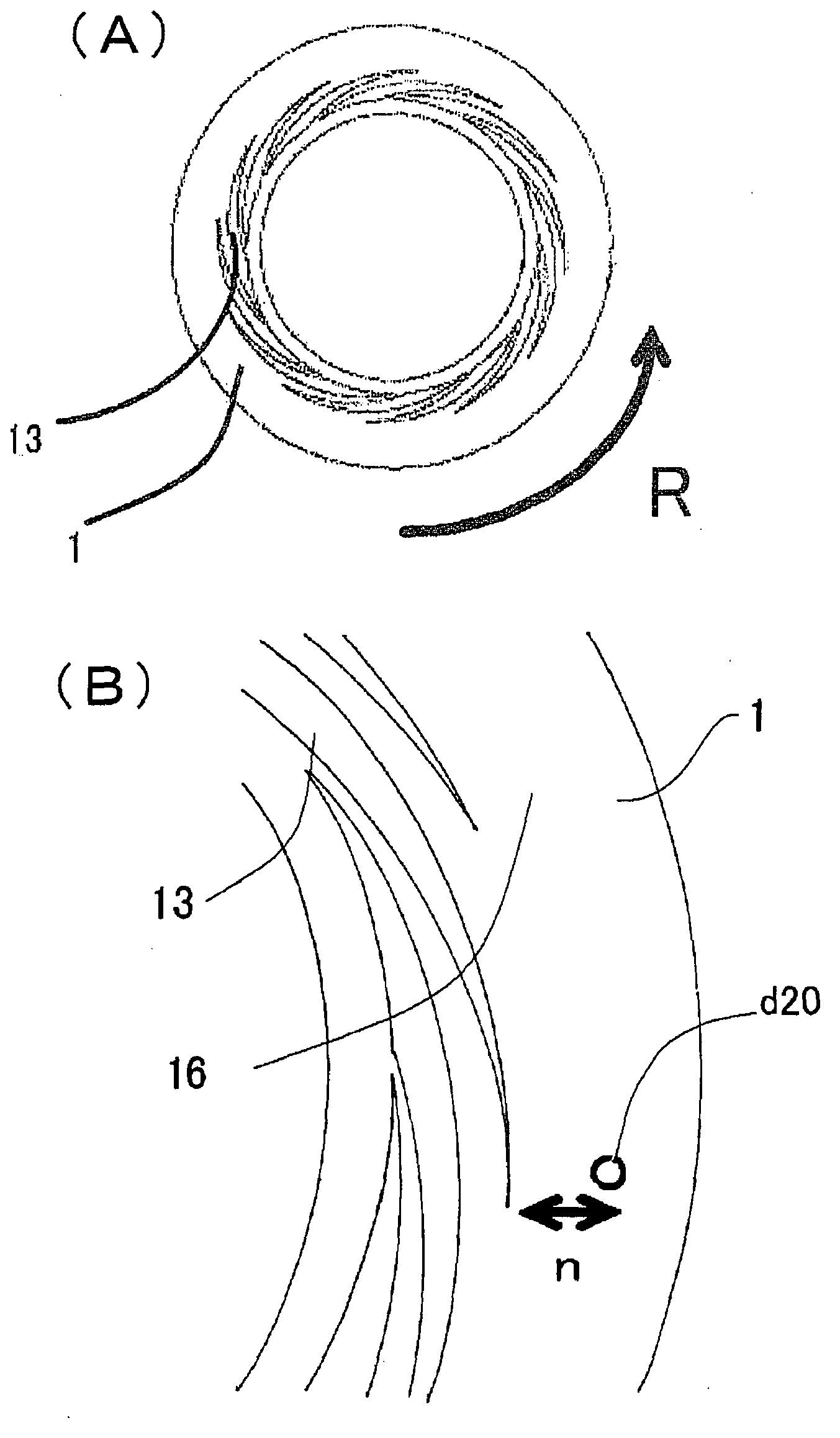

[0099] use figure 1 The dev...

Embodiment (1~5

[0108] While feeding methanol or pure water as the first fluid from the center at a supply pressure of 0.30 MPaG and a rotation speed of 300 to 3600 rpm, dissolve 2,9-bis in concentrated sulfuric acid (98%) as the second fluid. A 2,9-dimethylquinacridone solution of methylquinacridone (HOST PARM PI NK E(-TS): manufactured by Clariant, C.I. Pigment Red 122) was introduced between the treatment surfaces 1 and 2. The 2,9-dimethylquinacridone particle dispersion is discharged from between the treatment surfaces 1 and 2. The discharged 2,9-dimethylquinacridone fine particles were slowly aggregated, and centrifuged (×26000G) to settle. The supernatant after the centrifugation treatment was removed, pure water was added to disperse the 2,9-dimethylquinacridone fine particles, and the centrifugation was repeated again to wash the 2,9-dimethylquinacridone fine particles. The finally obtained paste of 2,9-dimethylquinacridone fine particles was vacuum-dried at 30° C. and −0.1 MPaG. Th...

Embodiment 6~9

[0113] While feeding methanol or pure water as the first fluid from the center at a supply pressure of 0.30 MPaG and a rotation speed of 1700 rpm, quinacridone (Cinquasia Violet) dissolved in concentrated sulfuric acid (98%) was used as the second fluid. R NRT-795D: C.I. Pigment Violet 19) solution of non-substituted quinacridone manufactured by CIBA was introduced between 1 and 2 surfaces for treatment. The non-substituted quinacridone microparticle dispersion liquid is discharged from between the treatment surfaces 1 and 2. The discharged non-substituted quinacridone microparticles were slowly aggregated, and centrifuged (×26000G) to settle. The supernatant after the centrifugation treatment was removed, pure water was added to disperse the non-substituted quinacridone fine particles, and the centrifugation was repeated again to wash the non-substituted quinacridone fine particles. The finally obtained paste of unsubstituted quinacridone fine particles was vacuum-dried at 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com